Khonaini ... manufacturing locally

Khonaini ... manufacturing locally

After undergoing major expansion, effectively doubling capacity, Global Pipe Company now aims to launch an IPO

Global Pipe Company (GPC), Saudi Arabia’s leading LSAW (Longitudinal Submerged Arc Welded) pipe manufacturer, which recently received a major purchase order from EPCI company McDermott for the supply of approximately 200 km of pipes for the kingdom’s mighty Marjan offshore oilfield development, is considering an initial public offer (IPO) soon.

Completing a major expansion through which a major second line is now in place, GPC has effectively doubled its plant’s nominal capacity to 400,00 metric tonnes (MT) and can work on two projects simultaneously.

'Now, after we have completed the investment plan for the company, we are planning to start the IPO process soon,' says Ahmed Hamad Al Khonaini, Shareholder and Managing Director of the company.

This will be a significant milestone and the next highlight in the short history of GPC, which has just completed a SR150-million ($40 million) upgrade at its Jubail facility.

The company had changed in January 2017 its legal status from 'Limited' to 'Closed Joint Stock', he explains.

'The closed joint stock status is an intermediate status on the way to an IPO,' Khonaini tells OGN in an exclusive interview.

The shareholders are thus considering listing GPC on the stock exchange in the near future.

|

Maher Fkaier, GPC General Manager, signing the MoU with Justo Acedo, CEO of Windar Renovables |

Meanwhile, GPC says the Marjan contract will encompass the production of about 101,000 MT of steel pipes for sour service application – in diameters ranging from 24 to 36 inches, and wall thicknesses from 20.61 mm to 38.1 mm.

'We are very proud to provide locally manufactured pipes for this prestigious national offshore project,' he says.

Going forward, GPC also plans to develop its international exports and explore new opportunities in the wind energy sector in the kingdom.

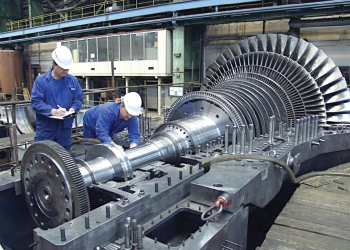

Like its first manufacturing line, GPC’s new line includes machines from well-known German suppliers. The equipment in the forming area was provided by German-Swiss company Haeusler.

A three-roll-bending machine was selected as forming machine for the new line. This machine is the right machine to roll pipes with big diameters and lower thickness.

The forming area also comprises a tack-welding machine from the German-Swiss company. The expander and the hydrostatic testing machine for the new line were provided by the German machine supplier SMS MEER.

The UT machines for weld inspection before and after pipe expansion were sourced from GE Inspection Technology located in Cologne in Germany.

The X-Ray equipment for the new line and a pre-bending machine were provided by the company AWS Schaefer, also a German machine supplier. The pipe transportation system connecting all these machines to a powerful manufacturing line was also provided by Haeusler.

Khonaini maintains that 'inspired by Saudi Arabia’s localisation policy and Saudi Aramco’s IKTVA program to increase the local content, we have selected machine suppliers maintaining local entities in the kingdom. We have also insisted that the contract for erection and commission of the equipment is signed with the local Saudi entity. This allows us not only to increase the local content, but also to secure local support for the new manufacturing line in the future'.

With the new manufacturing line, GPC has not only doubled its yearly average capacity, but also optimised the manufacturing processes increase productivity.

|

Three-roll bending machine in operation at the GPC mill |

Khonaini explains: 'For the first manufacturing line established with the company’s inception, we have selected a JCO-Press as the forming machine. The JCO machine is flexible to cover the whole diameter range from 16 inches to 62 inches and wall thickness ranging from 9.53 mm to 50.8 mm. However, this machine is slow in the forming of big diameter pipes. The new roll-bending machine is faster in this diameter range. Our plan is to run these pipes on the roll-bending machine in the future. By using the most efficient machines for each pipe size, we will be able to optimise our output and improve the quality of our products.'

With its expansion project, GPC optimised also the first manufacturing line by adding a pre-bending machine for pipes of heavy thickness. The trial runs performed with this new machine yielded good results. This allowed GPC to increase its approval range for heavy thickness pipes for Sour Service application for Saudi Aramco projects to reach 1.5 inch (38.1 mm).

The new line will also allow GPC to maintain its technology leadership in the LSAW manufacturing in the region.

The new manufacturing line is equipped with state-of-the-art machines and the most advanced technology for roll-bending, welding and full-body pipe expansion. The UT machines are equipped with Phased Array probes for best inspection results. The X-Ray equipment is ready for digital inspection mode.

The expansion of GPC’s mill and the resulting capacity increase will allow the company to serve the Marjan project in other packages also.

Khonaini says that the negotiations about the Non-Sour portion involving 72,000 MT of the same project are still ongoing.

'With our new manufacturing line and the increased manufacturing capacity, we are in the position to cover the whole quantity required in line with the expected project schedule. We are very keen to provide locally manufactured pipe products for this prestigious national project,' he says.

Khonaini reveals: 'While we have already submitted our bids for package 1 of the same project awarded to the EPC company McDermott, we are also very keen to provide welded pipes for package 2 of this prestigious project awarded to the EPC company Subsea7.'

Khonaini explains further: 'Our limited capacity before the expansion limited our participation in projects in the past and forced our customers to split the scope of the project by considering GPC only for a part of the project. It was also our common practice to decline bidding for new projects once we got a big project awarded. With the new capacity in place, we are very confident that we have solved all the capacity issues faced in the past. We are in a position to offer the full quantity for major projects. With two manufacturing lines, we are also in the position to work on two different projects simultaneously.'

Export development is also one of the major objectives that GPC is targeting with this expansion project. Even though the company executed the first export major job in 2017, its export contribution was very limited. The main reason behind this was the limited capacity.

Khonaini elaborates: 'In line with the strategy of the kingdom to raise the export of non-oil products from 16 per cent to 50 per cent by 2030, GPC’s board has decided to increase the manufacturing capacity of the company and allocate about 25 per cent of the yearly average capacity for export business. The increased capacity will allow GPC to serve projects outside the kingdom without losing focus on the local market which remains GPC’s highest priority.'

The first major export job for GPC was supplying about 28,000 MT to the TAPI project.

TAPI project is a cross-country pipeline connecting Turkmenistan, Afghanistan, Pakistan and India with a total length of about 1,900 km of 56' pipes in wall thickness ranging from 20 mm to 29 mm and X70 material grade.

GPC is working now to file a bid for the portions in Afghanistan and Pakistan. The company has already received a Letter of Intent (LOI) from the Saudi Industrial Development Fund (SIDF) for the financing of these portions.

GPC is also looking at export opportunities in Iraq. It is interested to supply pipes for projects of the Basra Oil Company (BOC).

GPC has worked since its inception to diversify its product portfolio. 'Today I am pleased announce that GPC will add wind towers to its product catalogue.'

The first of these farms is already under construction. GPC plans to fabricate wind towers locally to increase the local content at these wind farms. Most of the equipment required for the fabrication of sections for the wind towers is already available in GPC’s mill in Jubail. GPC on December 12, 2019 signed a Memorandum of Understanding (MoU) with the Spanish wind tower fabricator Windar Renovables SL. The target of this MoU is to develop a cooperation model for both companies on a wind tower project in the kingdom. Khonaini says: 'With WINDAR we have found a strong partner on our side to explore opportunities in the wind energy sector in the kingdom.'

Both parties have agreed to start the process to get GPC qualified as the first vendor for wind towers in the kingdom.

The cooperation between GPC and WINDAR is on exclusive basis and will cover, not only the steel fabrication of wind towers, but also coating services and secondary steel installation.