Al Hashim ... focus on latest technology

Al Hashim ... focus on latest technology

Using the latest technology, Gulf Industrial Services Company can immediately mobilise for any job in Saudi Arabia and other GCC states, says Managing Director Ahmed Al Hashim

Gulf Industrial Services Company (Gisco), a leading provider of integrated asset management and integrity solutions, claims to be the only Saudi company equipped and capable of doing online tank inspection using advanced robotic systems.

The company recently won the largest contract for online water tank inspection in the Middle East.

Ahmed Al Hashim, Managing Director, Gisco, told Abdulaziz Khattak of OGN the company signed an agreement with Marafiq-Sour Operation and Maintenance Company (Masa) to perform online cleaning, inspection, testing and repair of potable and reclaimed water steel tanks in addition to offline tanks inspection and repair in Jubail.

|

Gisco conducts American Welding Society exam in Al Khobar |

"The three-year contract includes the inspection of more than 52 large storage tanks, ranging from 68-metre diameter to 114-metre diameter using the latest robotic system," he says.

Gisco has already mobilised its team and equipment on site.

Also, last year, Gisco completed several tanks inspection as per the American Petroleum Institute (API) Standard in GCC and the largest ammonia tank in Jordan.

In the arena of tank, pipeline and vessel inspection, Gisco applies the most modern devices and latest innovative techniques to achieve quality results.

One such is the Magnetic Flux Leakage (MFL) Floormap storage tank bottom scanner. The system builds on the success of the software feature of top and bottom defect discrimination, and offers two advanced tools: MFLi (magnetic flux leakage-intensity) for search and verification; and Dynamic Cursor for defect sizing and classification.

"Together these innovative features achieve significant advances in corrosion measurement, with the potential to reduce inspection times and significantly enhance the quality of a tank inspection," says Al Hashim.

"This enables tank engineers to determine the optimum repair strategy and improve the outcome of fitness for service (FFS) assessments, remaining life assessment (RLA), and risk based inspection (RBI) programmes," he adds.

Also used during tank inspection is rapid motion Scanner—a high speed, high accuracy remote access ultrasonic corrosion mapping system designed to evaluate the condition of ferrous structures such as storage tanks, pipelines, pressure vessels and other critical equipment, supporting effective and safe operation.

The system can give 100 per cent coverage in a band up to 1,000 mm wide, significantly increasing probability of detection (POD) of corrosion, enabling engineers to determine the optimum repair strategy and improve risk life assessment, and risk based inspection maintenance programmes.

Established in 1993, Gisco has been in business for over 27 years, covering the entire Middle East region through its offices in Saudi, Dubai, Bahrain and Egypt.

Through strategic partnerships with industry leaders from around the world, Gisco offers clients world-class asset integrity solutions, while placing extreme emphasis on quality, safety, health, and environment.

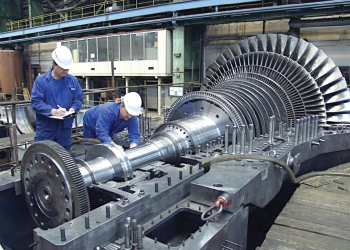

It services extend to various sectors, including offshore, oil and gas, power generation, and water and waste.

In addition to tank and vessel inspection, it does pipeline and tube and advanced inspection, and training and certification, while also offering underwater repairs, cleaning and coating, and engineering services.

An advantage of employing Gisco is its ability to mobilise immediately for any job in Saudi Arabia and other GCC, says Al Hashim.

For tube inspection, Gisco employs the latest technology. For example, the Ectane2 test instrument is approximately 10 litres in volume and weighs 6.8 kg, making it about three times more compact than other legacy test instruments. And its eight hours of battery power eliminates the need for an external power.

To inspect ferrous and non-ferrous tubing in heat exchangers, Gisco uses the methods such as eddy current, remote field eddy current, IRIS (ultrasonic), MFL, and magnetic bias.

|

Gisco carried out offline inspection of the largest ammonia tanks in Jordan |

For pipeline inspections, Gisco uses EMAT technology—an ultrasonic non-destructive testing method that relies on electro-magnetic acoustic interaction for elastic wave generation.

Also used here is long range ultrasonic testing (LRUT) to detect defects and imperfections some distance away from the ultrasonic source in a range of components.

This technology is particularly suitable for inspecting pipes that are insulated and buried, as a significant length of pipe can be inspected by uncovering a small amount of the pipe at a single location. In ideal conditions, 200 m of pipe can be screened from a single test location.

Gisco performs ships class survey according to ABS, DNV, Lloyds and BV classifications. Its hull survey inspections include but are not limited to special periodical surveys, intermediate surveys, load line surveys, and dry-docking surveys.

On the training side, Gisco has completed one of the largest events in the region for conducting training and exam for Sabic and Saudi Aramco technicians engineers related to both the American Welding Society certification and the American Petroleum Institute (API) in Al Khobar, Saudi Arabia.