A sulphur pit

A sulphur pit

Endress+Hauser’s 80 GHz radar sensor with steam jacketed nozzle improved reliability, enhanced safety, and significantly reduce maintenance costs Buildup inside a pipe

When a North American refinery faced operational challenges with its sulphur pit level transmitters, it turned to Endress+Hauser to implement an 80 GHz radar sensor paired with a steam-jacketed nozzle to enhance safety and increases productivity.

A sulphur pit is a storage facility typically constructed from concrete and located below grade in a refinery’s Claus Unit.

Its primary purpose is to temporarily hold sulphur extracted from the sulphur recovery unit (SRU) and maintain it in a molten state using steam coils submerged in the sulphur.

This molten sulphur is then transported to clients via trucks, railcars, trains or barges.

Molten sulphur often contains dissolved hydrogen sulfide (H2S) and other gases that need to be purified and removed from the process before transportation.

This purification process, known as degassing, is accomplished by sweeping the pit with air. The H2S and other impurities are then sent to treatment systems such as incinerators and thermal oxidisers.

The said refinery’s sulphur pit had, at least, one pump, often two for redundancy, to pump molten sulphur to transport equipment when there is demand and to circulate molten sulphur back to the pit when not pumping out.

|

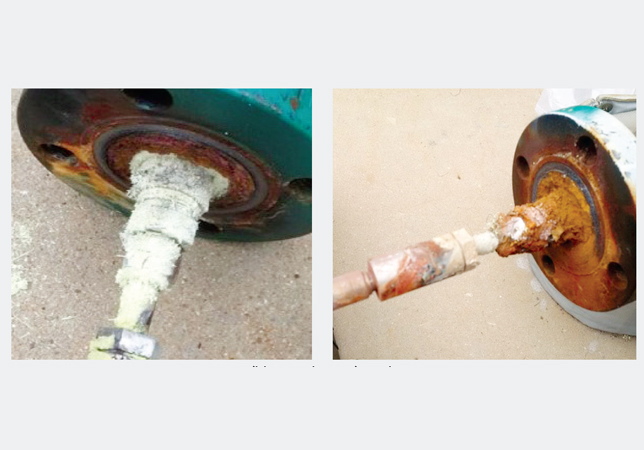

Hardened sulfur inside a valve |

The spray nozzles return the molten sulphur back to the pit, assisting with the degassing process.

However, as the sulphur disperses in the vapour space, it can form a residue on equipment and instrumentation such as free space radar cones, guided wave radar rods, thermowells and ultrasonic flowmeter probes.

This residue negatively impacts the accuracy of the measurements. Engineering control methods are required to prevent, eliminate or minimise the buildup, combined with good maintenance practices to ensure safe, accurate and reliable operation of the instruments.

Molten sulphur operates within a narrow temperature bandwidth, and its temperature must be controlled between 239-320 deg F (115-160 deg C) using saturated steam (10-75 psi, ideally 35-40 psi). If molten sulphur operates outside this range, it will solidify.

|

Buildup inside a free-space radar nozzle |

Based on field observations, two aspects were noted: Sulphur tended to form residue or fines below 239 deg F.

Above 310 deg F, its viscosity increased exponentially, making it so hard that pumps cannot flow or struggle to operate.

Therefore, maintaining uniform temperature distribution and tight temperature control is critical for ensuring equipment reliability.

The refinery had two 26 GHz radars on a sulphur pit that required frequent corrective maintenance due to sulphur solidifying on the nozzle. This posed three types of challenges:• Frequent maintenance: The sulphur pit radars frequently appeared on the refinery’s bad actor list, necessitating unplanned work orders that negatively impacted reliability KPIs.

• Safety risks: Manual cleaning of the radars exposed maintenance crews to hazardous sulphur vapour, requiring extensive coordination between maintenance, safety and operations.

>.jpg) |

Buildup on ultrasonic probes |

• High costs: Over a decade, the refinery spent more than $400,000 on sulphur pumps, with roughly $200,000 attributed to poor level measurement due to sulphur buildup on radar cones affecting measurement accuracy.

SOLUTION

To address these issues, the refinery performed a root cause analysis (RCA) and collaborated with Endress+Hauser and industry experts to implement an 80 GHz radar sensor paired with a steam-jacketed nozzle.

The RCA results included:

• Insulating all nozzles to prevent heat dissipation.

• Tracing all nozzles to prevent sulphur buildup.

|

Buildup on ultrasonic probes |

• Moving nozzles to locations further away from spray nozzles.

• Reviewing and upgrading level measurement technology.

The client reviewed various technologies, including capacitance probe guided wave radar, 26 GHz radar, and 80 GHz radar.

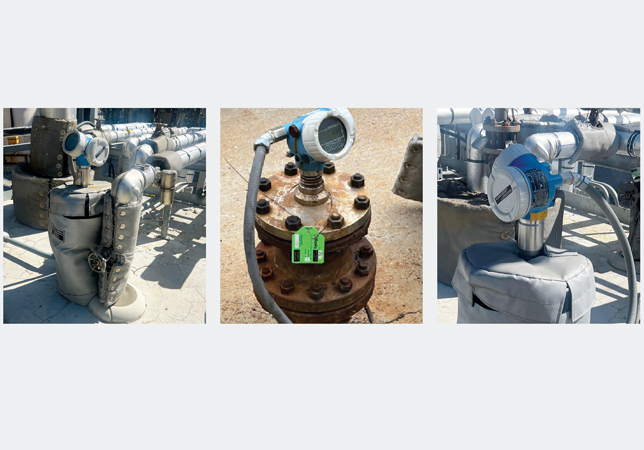

Ultimately, the refinery elected to use the 80 GHz radar sensor combined with a steam-jacketed nozzle for ideal heat distribution. This innovative solution provided several benefits:

• Improved reliability: The 80 GHz radar sensor offers high signal focusing with a 3-degree beam angle, allowing longer nozzle heights and reducing the impact of internal obstacles.

• Enhanced safety: The steam jacket prevents sulphur buildup, eliminating the need for frequent manual cleaning and reducing safety risks.

• Cost efficiency: Since the installation, the refinery hasn’t encountered challenges with buildup associated with sulphur pit level transmitters, significantly reducing maintenance costs.

RESULTS

The implementation of the 80 GHz radar sensor with a steam-jacketed nozzle has yielded promising results for the refinery.

Since the instruments were installed more than a year ago, there has yet to be any reported challenges with sulphur buildup, indicating a significant improvement in reliability and maintenance efficiency.

The elimination of manual cleaning has reduced the need for frequent cleaning, which has lowered the maintenance cost.

|

Endress+Hauser’s Micropilot FMR62B 80 GHz radar sensor on site at a North American refinery |

The reduction in maintenance requirements and the prevention of pump damage due to inaccurate level measurements have resulted in substantial cost savings.

The refinery has avoided the high costs associated with frequent repairs and replacements of sulphur pumps.

Additionally, the improved accuracy and reliability of the level measurements have enhanced the overall operational efficiency of the sulphur pit.

The refinery can now better manage the sulphur levels, ensuring optimal performance of the pumps and other equipment.

The investment in quality engineering and products has proven to be a successful formula, providing long-term benefits in terms of safety, efficiency and cost effectiveness.

The refinery’s proactive approach to addressing the challenges has set a benchmark for best practices in sulphur pit management.

'The most important result from this is the impact on safety and improved reliability,' said the customer.