Smart glasses used to remotely witness technology

Smart glasses used to remotely witness technology

From smart technology to on-site repair and testing, Ventil is committed to providing innovative solutions to improve efficiency and productivity

Ventil is committed to providing innovative solutions that enable valve companies to improve efficiency, productivity, quality and safety, Arthur Baars, Director of Innovation, Ventil, tells OGN.

Industrial values and pressure relief valves (PRVs) are final process elements and play a key role in the operation of every continuously generating process or power plant.

They block the pressure, regulate the process fluid and serve to protect ‘life and property’.

It is, therefore, obvious that integrity, reliability and safety can only be warranted when valves are given the right treatment,

The key elements to a quick and successful turn-around and even optimisation of the assets are, skilled technician and the right tools and test equipment.

Over the past 50 years, Ventil has developed an extended programme of delivery of machines, equipment and training courses, enabling valve repairers to quickly and efficiently turn any valve back to its original quality and working performance.

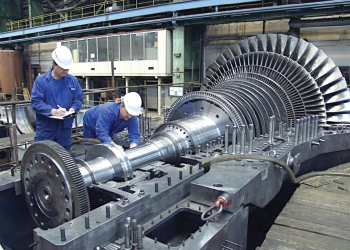

ON-SITE REPAIR & TESTING

When valves fail to perform and are in need of repair, time is of the essence. To reduce expensive plant downtime, full ‘on-site’ service is provided by the use of Ventil transportable valve repair and test containers.

|

Ventil's mobile overhaul container for onsite valves repair and testing |

The 10-ft, 20-ft and even 40-ft containers are fully equipped and prepared for fast track overhaul, repair and testing.

The scope of the transportable valve repair containers is either focused on PRVs or on a more universal character, reconditioning and testing shut-off valves and even control valves.

One large or a set of modular containers can be combined to create a large scale, on-site overhaul facility.

The Ventil containers are prepared for specific climatic conditions, use in potentially explosive atmospheres (Atex) and are certified according to DNV 2.7/EN 12079 for offshore applications.

An even more flexible and new solution is the Ventil Emergency Response Unit—a small size trailer suited for transportation by car or pick-up truck. The trailer is equipped for quick on-site repair and testing of pressure relief valves.

IN-SITU TESTING OF PRVS

The failure of PRVs to function properly can result in catastrophic damage and life-threatening situations. Periodical testing is needed to ensure these valves provide this ‘very important protection’.

The Ventil PreVenTest is an ingeniously-designed system for testing all types of spring operated PRVs, without disturbing the process conditions.

This means no dismantling of the valve, so no plant shut-down and no loss of productivity, and thus no loss of profitability.

The lightweight and portable PreVenTest system enables users to prove the correct performance of the valve or identify PRVs that need repair.

The valves are accurately tested without costly removal from the plant, and there is no need for temperature corrections because high temperature (steam) valves can be tested on site in ‘real’ process conditions.

Recently, the 500th Ventil PreVenTest was put to the test, some 10 years after its launch.

The system has become the system of choice in the valve service industry, being used on all continents by the most renowned valve repairers and valve manufactures.

TRAINING ACADEMY

As the industry evolves and big crew change marches on, knowledge and hands-on experience becomes crucial. Well trained personnel is the key to quick turnaround and assets optimisation.

Ventil has addressed the growing need for valve technicians by launching the Ventil Valve Academy (VVA), a training school for valve experts.

The programme starts with the basics and fundamentals about the common valves types and continues with a variety of courses on specific subjects like, for example valve automation, engineering and selection, valve repair and fugitive emission testing.

The strength of the VVA training courses for any valve manufacturer or brand lays in their great practical character and independent perspective.

ROADMAP TO DIGITAL TRANSITION

The latest development within Ventil is the Industrial Internet of Things (IIoT) and remote witness testing. The company is committed to providing innovative solutions that will enable valve companies to improve efficiency, productivity, quality and safety.

IIoT deployment allows plugging into the vast growing universe of connected equipment to get real time insights, secure data and automated decision making. And remote witness technology enables customers to save time and money by (co)witnessing or inspecting valve test assessments, through smart glasses, smart phone, tablet and stationary monitoring.

In other developments, digital ITPs are an innovative approach to digitally store and validate test data against applicable standards and client specifications. And virtual warehousing, exploring the benefits of automation of order management, expediting and document control (ORM).