A tank battery at Tatweer ... investments in digitalisation have contributed to efficiency

A tank battery at Tatweer ... investments in digitalisation have contributed to efficiency

The firm is conducting sophisticated technical studies to identify potential oil and gas reserves and is exerting great efforts to attract foreign oil companies to invest in projects in Bahrain, James Kenneth Eastlack, CEO of Tatweer Petroleum, tells OGN

Despite the many challenges the oil and gas industry has faced over the years, Tatweer Petroleum continues its strong performance, as the national oil and gas operator in the Kingdom of Bahrain strives to meet the rising demands of the Kingdom’s energy requirements.

The company continues to use new technologies, strategic planning and the development of knowledge and expertise to unlock additional petroleum reserves both onshore and offshore.

In an interview with Abdulaziz Khattak of OGN, James Kenneth Eastlack, CEO of Tatweer Petroleum, gave an overarching view of the company’s endeavours in maintaining Bahrain's oil and gas production levels and its future plans.

|

Eastlack ... exploring for new resources |

What are Tatweer Petroleum’s plans for this year? Are there any big project announcements in 2021?

The company is actively exploring for new resources while developing proven reserves. In addition to the appraisal programmes for the new discoveries in Khaleej Al Bahrain and Pre-Unayzah (Deep Gas), there are a number of exploration activities targeting potential oil reserves both onshore and offshore, including the upcoming exploration drilling operations with Eni in the North of Bahrain.

The exploration projects are not only limited to drilling wells; the team at Tatweer Petroleum is conducting a large number of sophisticated technical studies to identify potential oil and gas reserves. A huge effort is also being made to attract foreign oil companies to invest in projects in Bahrain.

Tatweer Petroleum is also continuing with ongoing projects on-shore in the Bahrain Field to maintain oil and gas production rates, despite the disruption caused by the Covid-19 pandemic, through the commissioning of new facilities and efficiency improvements/redundancy management through debottlenecking exercises.

From a technical perspective, we successfully introduced a unique complex stimulation approach to low-temperature carbonate formations. These shallow formations in the Bahrain Field have huge oil reserves in place (around 1.2 billion barrels), but have not been developed due to the complex nature of the rock. The approach used is a rare case worldwide when it comes to pumping large treatments using 12/20-mesh proppant in a shallow carbonate environment.

|

From a commercial and business development perspective, Tatweer Petroleum started a new era of partnership with top oil service companies by developing a new Risk-Reward Business Model. Service companies will invest jointly with the company in specific projects by providing unique and customised technologies to unlock reserves at maximum allowable risked rates and will be incentivised based on agreed key performance indicators (KPIs). This concept was successfully piloted last year with Schlumberger in the Ostracod-Magwa Risk Reward Project.

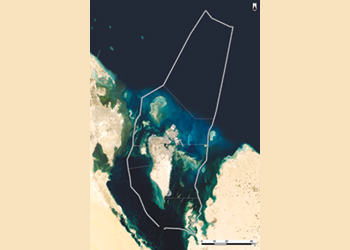

What are Bahrain’s prospects of developing reserves at Khaleej Al Bahrain?

Tatweer Petroleum is planning and preparing for an extensive appraisal programme for the Khaleej Al Bahrain basin in 2022. This programme will provide important information regarding productivity and marks the path towards developing the resource.

We will also continue reaching out to foreign investors and to sign additional joint studies, MoUs, and technical evaluation agreements and provide access to virtual data rooms and conduct roadshows. Our goal is to realise the leadership’s vision and maximise production of this valuable national resource. Apart from that, various new and existing projects will continue to maintain production rates in the Bahrain Field, using innovative technologies being employed across various reservoirs, and technical assessments and depletion plans put in place.

What was the total production in 2020, and how will Tatweer Petroleum maintain those levels?

The production of crude and condensate averaged 43,200 bpd, which is an increase of 800 bpd over 2019, while black oil production averaged 39,100 bpd for the year. The production of non-associated gas (NAG) was at around 1.7 billion standard cubic feet per day, meeting the Kingdom’s average and peak demands for energy. Tatweer Petroleum will continue to administer full field development projects to boost production.

|

What are some challenges the industry faces?

Aside from the rising energy demands of the Kingdom, the main challenge for the oil and gas industry is oil price. However, with advanced proper planning, we can adapt to the extreme volatility of the market.

Despite the major drop in oil prices in 2015 and the subsequent drop due to the Covid-19 pandemic, Tatweer Petroleum did not delay major projects and continued to produce at sustained production levels with slight increases.

Another challenge is the profitability of projects especially in mature fields, where expensive technology is required to unlock reserves in challenging complex subsurface environments, all the while optimising operational costs to increase the life of the field.

How much did Tatweer spend on contracts in 2020?

During 2020, the Supply Chain Management Department processed 2,179 commitments valued at approximately BD600 million ($1.59 billion) to cover the next 3 to 5 years of operations.

GAS

Can you brief us on Tatweer Petroleum’s drilling of new wells to increase gas production?

Natural gas demand in the Kingdom is expected to see robust growth in the coming years due to increasing demand for power and water, rising manufacturing sector consumption, and increased gas injection requirements for oil production in the Bahrain Field. As a result, Tatweer Petroleum began a major drilling campaign in the Khuff reservoir (the primary and dominant gas source in the Kingdom) to increase gas throughput from the Bahrain Field, and is also planning for a major reform in its upstream operations by installing wellhead compression and low pressure GDUs to maximise recovery from indigenous sources.

Additionally, Tatweer Petroleum has plans to develop tight gas formations and drilled a couple of wells in the deeper gas zones this year.

|

What is the latest on the mapping of Tatweer’s underground gas distribution network?

Apart from upstream development, Tatweer Petroleum is planning a paradigm shift in its gas distribution operations. The gas distribution network will undergo a major revamp to accommodate the increase in gas supply from the Bahrain Field.

Under the Gas Distribution Network Enhancement Project, Tatweer Petroleum aims to create additional pipeline capacity and flexibility to handle different types of gases of different pressures and flow regimes. In addition, we have commenced several projects to upgrade existing pipelines and to upgrade major distribution points.

Furthermore, these projects will integrate the recently commissioned LNG import terminal with the main distribution points to ensure all gas customers have access to LNG supply in the future.

TECHNOLOGY & ENVIRONMENT

How is Tatweer utilising technology to maximise value?

Tatweer Petroleum has strived to develop a culture that embraces technological changes and developments given the importance of technology to improve our efficiencies and provide solutions to the technical and operational challenges we face (whether in our existing or new fields).

Our professionals work closely with key global industry players to develop the required knowledge and experience to understand, pilot and implement technologies, which yield improved productivity and efficiencies.

What is your take on digitalisation and what is Tatweer’s strategy in this regard?

Breakthroughs in the fourth industrial revolution (IR4.0) have redefined a number of industries, and the E&P is not an exception; no industry can afford to stand still.

Tatweer Petroleum’s investments in digitalisation have contributed significantly to continuing operations during the Covid-19 pandemic. Our ‘Oil and Gas 4.0’ vision aims to re-imagine Tatweer Petroleum’s operations in terms of efficiency, with continuous commitment towards digital transformation, AI, and cloud computing.

The key areas where digitalisation can help optimise operations include exploration, drilling, and production operations. However, there are interesting digitalisation opportunities in supply chain, finance, and other business functions as well.

What is Tatweer’s policy regarding emissions control, environment protection, and carbon capture?

One of Tatweer Petroleum’s core values is to make efficient use of all natural resources, minimise waste, and reduce pollution.

The company has invested in many environmental projects targeting emission controls. These include the installation of numerous compression stations, which have resulted in the reduction of natural gas flaring and the retrofitting of several units with catalytic converters. We conduct routine emission tests from all stacks and the results are communicated to the Supreme Council from Environment (SCE).

In addition, our contracts make adherence to environmental laws and regulations mandatory.

As well as this, we constructed solar power plants (1 MW and 3 MW) in line with the Bahrain Government’s national renewable energy target of 5 per cent by 2025. Other environmental initiatives include engineered design facilities for managing different types of waste. We are also in the process of the construction of the Al-Hunayinah Sanctuary where we explore the potential use of produced water as irrigation media.

With regards to carbon capture, Tatweer Petroleum is exploring its use within our operations. The technology can be used in enhanced oil recovery and offers us the potential to increase production rates and maximise reserves. We are in the assessment phase working with sister companies under the National Oil and Gas Authority to utilise this technology in our operations.

How did Tatweer deal with the Covid-19 pandemic?

Tatweer responded swiftly by forming a Covid-19 Response Committee in the early stages to ensure employees and contractors followed all health and safety guidelines. Proper isolation and robust contact tracing in the event of positive Covid-19 cases kept the company’s infection rate tremendously low.

A hotline number was created to bolster communications with employees and contractors and ensure a prompt response to any reported case. This was in addition to awareness campaigns and publications aimed to curb the spread of Covid-19.

What programmes does Tatweer offer to upskill the Bahraini workforce?

Tatweer Petroleum maintains a high Bahrainisation rate (over 86 per cent in 2020) and continues to develop Bahrainis through leadership training programmes in order to prepare them for future roles. Additionally, all Bahraini employees follow individual development plans to train and develop them in their respective fields of responsibility.

.jpg)