.jpg) GPIC signed an agreement with Saipem in 2020 to study production increase

GPIC signed an agreement with Saipem in 2020 to study production increase

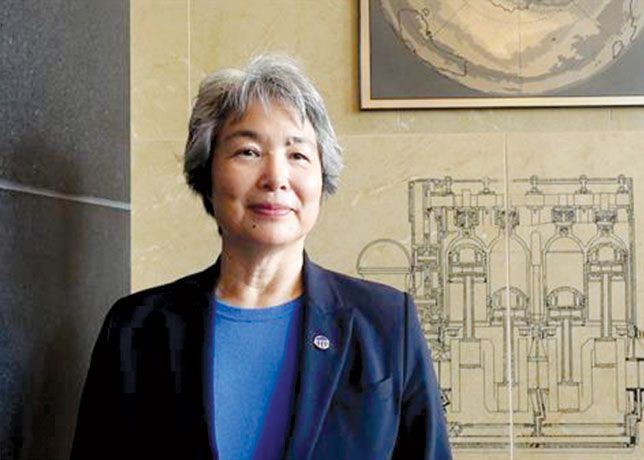

Discussions with Saipem to evaluate the proposal for increasing daily production at the urea plant are in the advanced stages, Dr Abdulrahman Jawahery, GPIC President, tells OGN

Despite the challenges posed by the Covid-19 pandemic, the Gulf Petrochemical Industries Company (GPIC) was able to turn 2020 into a successful year in terms of production, safety, health, environmental protection and reliability of its plants.

In an interview with Abdulaziz Khattak of OGN, Dr Abdulrahman Jawahery, GPIC President, highlighs the developments in the past year and future plans.

• Last year, GPIC tasked Saipem to study the feasibility for three projects. What is the latest on these studies and projects?

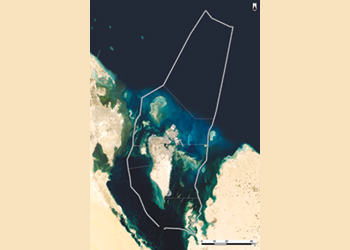

The MoU signed with Italian oilfield services company Saipem is part of the Gulf Petrochemical Industries Company’s (GPIC) strategy to expand operations and build on recent successes, by studying the viability of implementing new projects within its industrial complex at Sitra and to leverage the discovery of Bahrain’s largest shale oil and gas reservoir at Khaleej Al Bahrain.

|

Jawahery ... GPIC scored a productive 2020 |

The agreement will enhance GPIC’s ability to increase production and expand its contribution to the Kingdom’s economy in line with the directives of His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince Prime Minister.

Technical discussions and communications with Saipem are underway and we are currently in the advanced stages (engineering stage) to evaluate the proposal to increase daily production of our urea plant.

With regards to the mega ammonia/urea plant, we are still waiting for the results of new shale gas discoveries at Khaleej Al Bahrain.

The Minister of Oil, Shaikh Mohamed bin Khalifa Al Khalifa, has highlighted GPIC’s proven excellence in production and marketing, assuring full support of both the government and GPIC’s shareholders to the company’s expansion.

• How has GPIC’s shareholders impacted the company in terms of transfer of technology and knowhow?

No doubt that one of our strengths is our shareholders; Saudi-based SABIC Agri-Nutrients Investment Company and Kuwait-based Petrochemical Industries Company (PIC) are both global giants in the fields of petrochemical, fertiliser and chemical manufacturing.

PIC started manufacturing petrochemical products very early in the 1960s and has successfully diversified its business through numerous successful joint ventures worldwide. SABIC on the other hand has established itself as a leading global chemical and petrochemical beacon. This was further strengthened by its takeover by Saudi Aramco with majority shares in SABIC.

The futuristic vison of these shareholding companies, human capital investment and strategic enhancement of research and development merited them this status and equipped them with unique capabilities to become industry leaders today.

|

GPIC's dedicated workforce continues to make the company a pioneer in |

We at GPIC have established an extraordinary and mutually respectful relationship with our shareholders, and have further solidified this by working together as one team and exceeding each other’s expectations in terms of world-class performance and international achievements. This relationship and professionalism opened the doors of SABIC and PIC to our teams to interact with their counterparts in events, congregations and conferences.

Every CEO of SABIC and PIC and almost all their executive team members have visited GPIC and treated it as one of their local affiliates, and hence extended all their services, facilities and knowledge to our staff members in fields such as operation, technical services, safety, environment, audit, turnaround, IT and many other areas of operation.

For example, our implementation of SAP (ERP) systems was done using SABIC’s methodology and experience. Our IT team visited SABIC implementation team prior to finalising our project and the result was a smooth, cost-effective and fast implementation.

GPIC employees attend Noga, SABIC and PIC technical forums, special events, and marketing meetings. We even invite each other to celebrations and milestone achievements to share moments and key learnings.

The GPIC’s Board of Directors is keen on sustaining this level of cooperation between the three shareholding companies for its positive impact on sharing knowledge, reducing cost and bringing people closer to each other.

• GPIC's carbon dioxide (CO2) recovery (CDR) plant was the first of its kind in Bahrain. How has that helped the company in its sustainability goals?

GPIC is one of the first petrochemical companies in the Middle East to embark on a carbon dioxide recovery (CDR) project to cut down greenhouse gas (GHG) emissions and to improve overall efficiency of natural resources through enhanced production of methanol and urea in its complex.

GPIC’s CDR unit utilises state-of-the-art and commercially proven technology from Mitsubishi Heavy Industries, Japan, to recover CO2 from the methanol reformer flue gas stack. It has helped in substantially minimising CO2 emission into the atmosphere. The unit captures 450 tonnes of CO2 per day, resulting in emissions reduction by 165,000 metric tonnes annually.

The recovered CO2 has been used in our plants to increase annual methanol production by 44,000 metric tonnes (MT) and urea production by 55,000 MT. The project was completed successfully in December 2009 ahead of its planned schedule. Since 2009 GPIC’s CDR plant has captured more than 1.4 million tonnes of CO2. By doing this, GPIC is contributing to the UN 17 sustainable development goals (SDGs), mainly SDG 13 (Climate Action) and SDG 12 (Responsible Consumption and Production).

• What was GPIC’s total production target for 2020, and how much of it was achieved?

GPIC’s total production target for 2020 was around 1.5 million tonnes (mt). Of this, the urea production target was 651,100 mt, ammonia 425,200 mt, and methanol was 412,360 mt.

The company exceeded those production figures. Accordingly, urea production reached 718,793 mt, ammonia 463,875 mt, and methanol was 450,097 mt.

• Will GPIC increase its production capacity in 2021?

GPIC’s production capacity (target) for 2021 also sits at around 1.5 million tonnes. Of this, the production target for urea is just over 650,880 mt, Ammonia 429,080 mt, and methanol is 414,510 mt.

The lower production target in 2021 compared to 2020 is due to a scheduled major turnaround in November 2021 after four years of continuous operations.

• How much capex has GPIC allocated for 2021, and what will it be used for?

GPIC’s capex is directly linked to its scheduled maintenance turnaround cycles, which typical run every 30 to 36 months. Last year was supposed to be a planned turnaround but due to the Covid-19 pandemic, that was deferred to 2021. Most of the anticipated capex for 2020 turnaround year was successfully sourced and completed.

Since 2022 is a non-turnaround year, the capex will hence commensurate with general safety, reliability and HSE compliance projects.

• How did GPIC deal with the Covid-19 pandemic?

In response to the crisis, we at GPIC quickly focused on our most critical needs and the safety and sustainability of the plants and production. We streamlined our procedures and for as many employees as possible we rapidly embraced a work from home and remote meeting culture to speed up decision-making, policy discussions, technical assistance, and training.

Despite all the challenges posed, we have been able to turn 2020 into a successful year in terms of safety, health, environmental protection and reliability of plants. Our resilience to overcome this year’s challenges is attributed to our incredible board of directors, GPIC team, and employees, who through their loyalty, discipline and professionalism have contributed significantly to these remarkable achievements. The ideas, the skills and the dedication of our workforce, continues to make GPIC a pioneer in best practice and sustainability for the past 41 years.

We kept our employees continually updated with the situation and issued directives and memos to keep them aware of the situation and what was expected of them on subjects such as Covid-19 health precautions, overseas travel and isolating directives, measures to control Covid-19 spread, closure of GPIC recreational facilities, reducing the number of employees in communal areas, virtual and home-working protocols, Covid-19 shift roster, GPIC employee Covid-19 testing, establishing a Covid-19 crisis management team, and Covid-19 vaccination information.

We also launched a short animated film for all staff to illustrate our expectations once they returned to work, to ensure we keep everyone safe while maintaining a sustainable operation.