The Faccin HAV rolling machine ... one of the largest in the region

The Faccin HAV rolling machine ... one of the largest in the region

The Faccin HAV machine is one of the largest in the Middle East and sets the Saudi company to become the point of reference in the market for the manufacturing of super heavy-duty steel plates, Federico Bonfogo of Faccin tells OGN

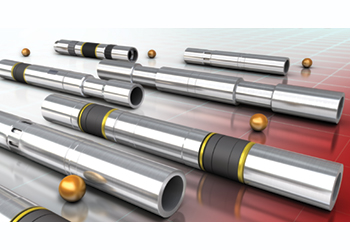

Faccin has delivered one of the largest heavy-duty plate rolling machines to a leading manufacturer in the Kingdom of Saudi Arabia to boost its production capabilities.

The Saudi holding company, which operates in several businesses and leads in the production of pressure vessels, columns and reactors, heat exchangers and process equipment, is the new house for a 5,000-tonne force Faccin HAV rolling machine.

According to Federico Bonfogo, Faccin’s Group Senior Technical Sales Manager: "This machine is believed to be one of the largest, if not the most powerful, in the whole of the Middle East and sets the Saudi company to become the point of reference in the market for the manufacturing of super heavy-duty steel plates."

The oil and gas market has gone through important changes over the recent past becoming more competitive on a global scale. One of the main goals of Faccin’s R&D department has historically been to provide oil and gas equipment manufacturers with advanced solutions to their rolling needs with the aim to get the maximum accuracy and productivity especially when rolling heavy and super heavy-duty steel plates.

"Thanks to Faccin’s experience in the construction of super heavy-duty forming machines, the continuous innovation, the prompt after sales service and indeed its presence in the Gulf market, Faccin has been the choice for this challenging project," says Bonfogo.

A three-roll motorised Faccin HAV plate rolling machine with a total force of 5,000 tonnes is able to bend plates over 300 mm, and is a perfect combination of power and precision, and ideal for job shop and heavy duty applications. It is suitable for:

• The widest range of thicknesses for maximum versatility.

• Accurate pre-bending with minimum material waste.

• Heavy-duty rolling.

• High tolerances calibration after welding for maximum quality.

The machine was supplied with the advanced Siemens CNC Numerical Control PGS Ultra — the first revolutionary system for automatic circular and conical rolling — as well as the new Capacity Planner software, which helps the operator to manage the machine capacities and jobs feasibility.

Also included was the Faccin AP package, an advanced hydraulic system aimed to increased productivity and precision thanks to the simultaneous movement of the rolls rotation and position, with the finest positioning of the same.

Finally, the innovative Cloud Remote Service Management, with a track record of 90 per cent cases solved in a few hours, always ensures a prompt service assistance (with a track record of 90 per cent cases solved in few hours.

The HAV model, produced by Faccin since the 1980s and with of thousands of successful installations, are machines with a proven optimised design featuring a heavy-duty oversized structure, three motorised rolls for full traction of the plate, and a minimum offset of the rolls for extra-short flat edge after pre-bending.

This innovative machine is nowadays the perfect answer to any heavy-duty steel plate rolling production challenge.

Faccin is part of the reliable and powerful Faccin Group, a leading global metal forming machine manufacturer that provides a wide range of bending machines and can count more than 30,000 units successfully installed all over the world.

The group is focused on the production of plate rolling machines, angle rolls, dished head lines and special solutions serving several industries.

The company has a corporate headquarter in Italy, branches in the US and Germany, and sales offices in Spain, China and the Asia Pacific in order to provide prompt assistance to all customers globally.

For more information about Faccin heavy duty rolling machines, write to info@faccin.com.

.jpg)