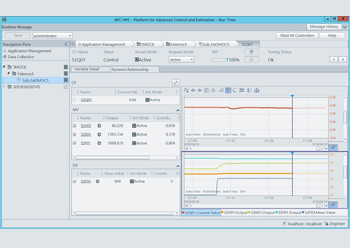

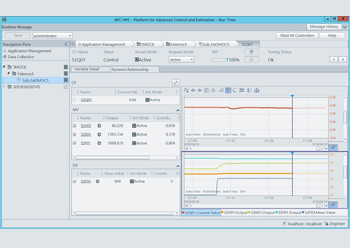

Platform for Advanced Control and Estimation R5.02

Platform for Advanced Control and Estimation R5.02

The R5.03 is an asset operations and optimisation solution that improves plant systems interoperability and security through support of the OPC UA communication standard, says a company spokesman

Yokogawa and Shell have jointly developed a software platform for advanced control of continuous plant processes in the oil, petrochemical, chemical, gas, and other industries

The Platform for Advanced Control and Estimation R5.03 will be released on June 2 as a solution under the OpreXTM Asset Operations and Optimization family.

Yokogawa has continued to enhance this suite in response to changing customer requirements. The release of version R5.03 meets urgent industry needs for enhanced plant systems interoperability and security.

“The software suite brings together Shell’s advanced plant process control technology and Yokogawa’s real-time control technology to help customers improve productivity by increasing product yield and reducing energy consumption,” says a company spokesman.

The version upgrade supports Open Platform Communications Unified Architecture (OPC UA), the latest version of a communication standard that improves plant systems interoperability and security, and provides the basis for digital transformation to help customers transition to industrial autonomy.

OPC UA is recognised as a communication standard for Industry 4.0, benefitting from high security and scalability without hardware or OS dependence.

According to the spokesman, advanced process control (APC) systems improve product yield and reduce energy consumption by maintaining temperature, flow rate, pressure, and other process values within a set range and keeping them as close as possible to their optimal set points. Such systems are increasingly used in facilities such as oil refineries, petrochemical plants, chemical plants, and LNG trains.

Yokogawa’s Platform for Advanced Control and Estimation suite delivers functionalities including:

• Multivariable model predictive control (the control of multiple variables based on predictions made using models of the dynamic characteristics of plant responses).

• Soft sensing for estimating quality in real-time based on temperature, flow rate, pressure, and other process values.

• Customisation of calculations.

The R5.03 includes several enhancements in terms of features expansion:

• Support for OPC UA: The new version conforms to OPC UA, the latest version of the OPC communication standard, and this enables users to securely exchange data with OPC UA devices and work with data from a wider range of sources.

• Addition of new Base Layer Control (BLC) model: A new BLC model that employs proportional integral differential (PID) control logic has been added. This model uses the PID parameters of a distributed control system (DCS) to represent the dynamics of a PID loop. This improves control by reducing mismatches with the process described by the BLC model.

• Expansion of Shed Logic to Event Logic: Shed Logic is a function that customises how applications operate. It gives users the freedom to customise the behaviour of their applications to suit the operating conditions of a plant. Shed Logic is now called Event Logic, with expanded functionalities that eliminate the need for custom code and enable event-based processing for measurement validation, model change, etc.

The R5.03 also has improved maintenance features, including:

• Design-Time advisor: This function verifies the parameter values for applications, processors, and variables that have been set using Design-Time and displays a warning message for any invalid parameter settings. By making it easier to identify and correct configuration errors, this helps to improve applications.

• Automatic trend scaling: The scale of the trend pen (upper and lower limits of the trend display) can now be adjusted automatically. This feature reduces the time and effort required for setting the trend scale.

• Visualisation of OPC performance data: It is now possible to view OPC performance metrics such as read time when accessing data from an OPC data access/unified architecture (DA/UA) server. In addition, a list can be displayed that shows all accessible OPC items. This feature makes the diagnosis of OPC DA/UA access easier.

In the R5.03, applications are more robust and run faster. Also, lab updates take significantly less time to perform and are more robust.

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business. This brand comprises the OpreX Transformation, OpreX Control, OpreX Measurement, OpreX Execution, and OpreX Lifecycle categories.