The Levelflex FMP55 multiparameter device for interface measurement

The Levelflex FMP55 multiparameter device for interface measurement

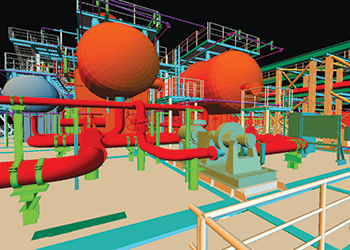

Two different technologies, GWR and Capacitance, are combined in a single instrument to derive the advantages of both technologies

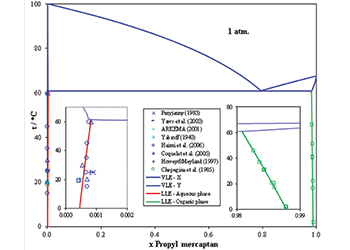

Interface measurement is always a challenging and critical application in the hydrocarbon industry. Ideally the separation between two media with different densities results in a clearly defined interface line. Practically, however, a transition layer often develops between the two media, a so-called emulsion layer.

An emulsion is formed when two non-soluble liquids (like oil and water) are agitated together to disperse one liquid into the other, in the form of drops. Emulsions can either be oil-in-water (O/W) or water-in-oil (W/O), depending on whether the continuous phase is the water or the oil, respectively.

"There are many technologies available in the market, but none of these technologies provide satisfactory measurement results," says Sivaji Nemalipuri, Product Manager - Level & Pressure, Endress+Hauser.

Guided wave radar (GWR) will provide only top-level measurement when an emulsion layer exists and cannot provide interface measurement when emulsion layers exceeds more than 60 mm. Capacitance probes are a well proven and preferred technology for interface measurement, but it cannot provide top level signal. Other technologies like DP transmitters or displacer level transmitters also have some limitations.

After thorough research on interface application measurement techniques, Endress+Hauser developed the SensorFusion technology. This is a combination of two different technologies in a single instrument: GWR and capacitance technologies are fused into one device to derive the advantages of both technologies.

The two technologies were chosen because of:

• Capacitance technology’s proven track record performance with emulsion layers.

• GWR’s performance for overall precision level.

This innovative and redundant approach brought about a revolution in interface measurement solutions. It is not only a precise and reliable solution, but it is also cost effective. This multi-parameter transmitter can measure the overall level of liquid and interface between the two liquids. The switch between GWR and capacitance technologies is automatically made to provide concise and reliable interface measurement, even in the presence of emulsion or rag layers. This device can withstand temperatures up to 392 deg F (200 deg C) and pressures up to 580 PSI. Interface range up to 33 ft can be measured and is available with different probe options like coaxial, flexible and rod types. This sensor fusion technology device has advanced features like HistoROM, SIL Certified, multi-echo tracking, etc. Due to the advanced features, the device has numerous and advanced benefit, for example, in the event of electronics replacement due to failure, data can be fed automatically from HistoROM to new electronics which saves maintenance time.

For processes where interface layers are present, a precise measurement is decisive for the safe control. The availability of the measuring point and process safety are of the utmost importance in the operation of any plant.

The benefits of using SensorFusion technology include:

• Reliable measurement for interface and top level even if an emulsion layer exists.

• Process density changes will never influence measurement performance.

• Exact instrument and process diagnosis to assist fast decisions.

• Measure and assign additional diagnostic information, like relative echo amplitude, which will ensure effective demulsifier dosing.

• This device can be used in safety loops.

.jpg)