Moshi and Bou Mitri (right)... supporting in-Kingdom solutions

Moshi and Bou Mitri (right)... supporting in-Kingdom solutions

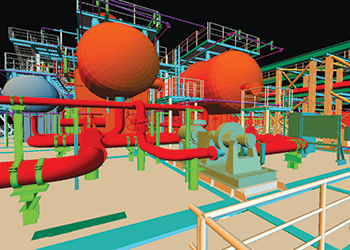

The Callidus Flare Technology production facility will reduce flaring and the Elster Instromet Saudi Arabia will will offer extensive technologies for gas and liquid metering, as well as control applications for the oil and gas industry

Honeywell has launched two projects in Saudi Arabia that contribute towards Vision 2030 and the In-Kingdom Total Value Add Program (IKTVA), enhancing the Kingdom’ economic diversity and industrial sector by localising manufacturing and creating new jobs in manufacturing and engineering.

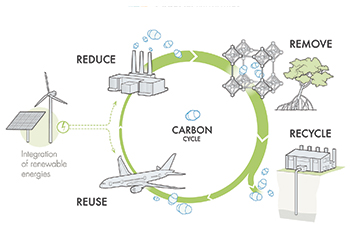

The Callidus Flare Technology production facility in Jubail industrial city bring the lowest steam consumption flares to help reduce the carbon footprint of the Jubail petrochemical complex.

The Callidus facility will be the first of its kind in the complex, in proximity to several Saudi Aramco joint ventures, Sabic affiliates as well as private-sector petrochemical plants.

Callidus Technologies, which specialises in thermal combustion products for the oil and gas industry and is a world leader in flare technology, designs and manufactures flares that range from simple utility flares to high performance ultra-low-steam nViroTM XSR Flares.

'With thousands of installations worldwide, UOP Callidus flare systems provide proven economical flaring with high destruction efficiency, high smokeless capacity, low noise and low radiation for a broad range of flare applications,' says Jim Moshi, General Manager, Honeywell UOP Middle East.

'With this state-of-the-art technology, petrochemical plants can greatly contribute to reducing their carbon footprint.'

Honeywell has also launched a new production facility for oil and gas projects that primarily aims to service approved solutions for Aramco.

Named Elster Instromet Saudi Arabia, the facility has been developed jointly with Gas Arabian Services to provide a state-of-the-art infrastructure for manufacturing and assembly of natural gas and liquid fuel solutions.

A key part of the new facility is the use of Elster precision solutions, a portfolio of Honeywell solutions that include extensive, end-to-end technologies for gas and liquid metering, as well as control applications for the oil and gas industry.

Through the facility, Honeywell will offer both skids and stations solutions, along with automation and control systems.

The new facility will lead to enhanced local skills and capabilities for future developments, and will help create at least 20 additional jobs in the Kingdom.

'Honeywell has been serving the Saudi market with instrumentation, control systems and advanced application solutions for many decades. The new facility will help drive knowledge transfer and support the creation of highly skilled roles,' says George Bou Mitri, Vice¬-President and General Manager for Honeywell Performance Materials and Technologies in the Middle East.

'Our solutions will support the oil and gas sector domestically and across the region by increasing reliability, decreasing maintenance costs and driving future growth.'

Located in the Royal Commission area of Jubail, the facility includes a 2,000 sq m workshop and more than 1,000 sq m in office space for handling in-Kingdom projects, including manufacturing and assembling.

The facility will mainly cater to the Saudi and GCC markets, but will in the future support projects across the world.

'This new facility is another chapter in our 70-year Saudi history, creating new opportunities and supporting in-Kingdom manufactured and assembled solutions to advance the critical oil and gas sector,' says Mitri.

'Saudi Arabia is a high-growth, strategically important market for Honeywell. We remain fully supportive of the country’s Saudisation efforts and continue to invest in knowledge transfer programs as well as locally-based facilities to support the objectives of the long-term national vision.'

.jpg)