The SLC headquarters in Riyadh ... supplying prestigious clients including Sabic

The SLC headquarters in Riyadh ... supplying prestigious clients including Sabic

Saudi Lighting Company (SLC) has expanded and developed its products and manufacturing processes according to the economic development and marketing response, according to the company.

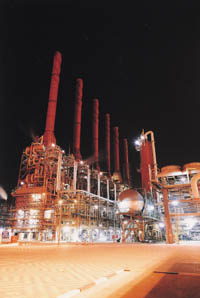

Since 1978, SLC has been producing outdoor lighting fixtures in participation with Sweden's Asea Company. In 1989, SLC merged with Arabian Lighting Company in manufacturing indoor lighting fixtures. With this merger, SLC has since grown to become the leading manufacturer of lighting fixtures in the Middle East and has been continuously meeting customers' demands. The company has supplied many of the most prestigious oil, gas and petrochemical projects - including Saudi Basic Industries Corporation (Sabic) and Saudi Aramco - in the Kingdom in recent years, and has adapted its range of products in that time to meet demand in the country. One of the most important lines produced by the company since 1995 is hazardous lighting, a topic which, until then, had generated little solid manufacturing support in Saudi Arabia. By producing hazardous area lighting, including explosion-proof products, SLC was able to supply local industries, which previously had to look overseas for their needs. And by offering a manufacturing facility in the Kingdom, SLC is able to offer significant cost advantages and well as quicker lead times. SLC produces lighting fixtures to the highest national/ international quality standards - including Saudi Arabian Standards Organization (Saso) and ISO 9001 quality system standards. In order to provide guarantee quality and accuracy, the company has purchased new digital and automatic control machines, which are used in all steps of the manufacturing process including cutting, punching, roll forming, bending or in stages of part product assembly. Testing and research are also crucial aspects of SLC's business. Claiming to use the most advanced lighting laboratory in the Middle East, SLC is able to ensure that its products meet stringent standards of quality. Lighting characteristics and photometry are subject to close scrutiny and verified in a goniophotometer to ensure adequate light distribution. The functionality and electrical safety of all products is also tested under rigorous conditions to verify IP ratings and classifications and to meet international standards such as IEC598. Indeed, quality and technology are recurring themes as SLC introduces new products and builds on its extensive experience in the Kingdom towards an even brighter future.