The VANTAGE product suite provides a comprehensive set of Engineering Plant lifecycle solutions

The VANTAGE product suite provides a comprehensive set of Engineering Plant lifecycle solutions

Technology from UK-based Cadcentre has been integral to the engineering process of industrial plants with a value in excess of $500 billion for more than 700 worldwide clients in 50 countries, according to the company.

As a world-leading developer and provider of engineering IT solutions and services for the plant lifecycle in the process and power industries, Cadcentre has used more than 17,000 installed systems to carry out its services.

Cadcentre is now an established and recognised leader in its market, enjoying strong and enduring relationships with its customers.

The company has experienced rapid growth in business in the Middle East and, as a direct result, recently opened an office in Saudi Arabia to support Cadcentre's continued expansion strategy, enabling unrivalled support to its customers at both a global and local level.

As well as increasing the number of offices globally, Cadcentre is continually expanding its range of engineering IT software and services.

The company is set apart from the competition with its core philosophies of active innovation, evolutionary development of products, proven open technology, unrivalled support and service, and an established track record in bringing exciting and beneficial new technologies to market.

Cadcentre has long been a technical leader with its integrated and data-centric approach to engineering, enabling optimal use of design time and total data consistency throughout the project.

To deliver these business values to market, the VANTAGE product suite provides a comprehensive set of integrated Engineering Plant Lifecycle solutions.

Based on best project practices through a single information model and structured workflow providing a concurrent environment for project teams to work over distributed locations using low bandwidth technology infrastructure, and encompassing the functional areas of plant engineering, plant design and project resource management, the solution in whole or in part is a fully-integrated workflow system which can deliver significant business improvements in effectiveness, efficiency of engineering and cost reduction, Cadcentre says.

In addition the VANTAGE Plant Engineering suite is for companies that want to improve:

In addition, Cadcentre also offers its VANTAGE Enterprise Integration suite as its business integration services hub.

This enables Cadcentre to offer business systems integration for the entire plant lifecycle and deliver open and flexible information access to the wider enterprise, regardless of the information source.

The flexibility of the Enterprise Integration technology offers ''next generation'' business integration solutions that overcome many of these obstacles through a combination of data consolidation and application federation.

This approach means that ''static'' and poorly structured sources can be targeted for integration by data consolidation, while ''dynamic'' data sources and key enterprise business systems can be integrated by federation through managed information portals.

The VANTAGE Enterprise Integration suite is for companies that want to improve their information effectiveness within the enterprise and across the plant lifecycle.

The VANTAGE Enterprise Integration solutions can be configured to best exploit cost reduction through effective information access and decision support to consolidated data sources and content.

Sabic and ABB chose VANTAGE Engineering Plant Lifecycle Solutions.

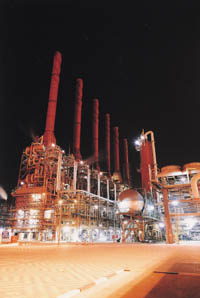

The benefits of these changes have been recognised by the Al Jubail Petrochemical Company (Kemya) - a 50:50 joint venture between Sabic and ExxonMobil Chemical Arabia - and ABB who have recently completed the design and construction of the Kemya petrochemical plant in Saudi Arabia.

Kemya utilised VANTAGE Plant Design (PDMS) in its operations and maintenance revamp and rework activities in the engineering design office.

Kemya also utilised VANTAGE Plant Design REVIEW for realistic plant visualisation in evaluating construction schedules in the plant's programme.

This 700,000 tonnes per year (tpy) ethylene and 200,00 tpy propylene plant, with a contract value of $400 million, is one of the largest lump sum EPC projects handled out of ABB Lummus Global's office in The Netherlands.

This project has many notable achievements: the project was kept on schedule and within budget, with a 30.5 month schedule from contract award (start of engineering) to handover (mechanical completion).

In an increasingly competitive global market choosing the right process technology is a major concern for the plant owners.

With lead times becoming shorter and costs being driven downwards it is important to bring the contractors into the cycle as early as possible.

ABB achieved this by achieving virtually concurrent execution of the design, engineering, procurement and construction stages, with schedules being shortened considerably.