Saudi Chevron ... defining moment

Saudi Chevron ... defining moment

New investment laws in Saudi Arabia are encouraging more private ventures to build petrochemical plants in Jubail and Yanbu.

But rather than being viewed as potential competition for the established Sabic affiliates in the industrial cities, these 'new kids on the block' will provide opportunities for cooperation and some integration of feedstocks, according to the Corporation.

Analysts expect the private sector to establish more value-added petrochemical industries in joint venture and partnership with international companies.

Saudi Arabia has put in place attractive incentives which are encouraging private investments - both local and foreign - in downstream petrochemical ventures.

Abdulaziz A Al Zamil, chairman of the Saudi International Petrochemicals Company (SIPC) and former Minister of Industry and Electricity, said earlier this year that the Kingdom's petrochemical industry ''will continue to be a driving force in the economic stability of the country.''

Large reserves of raw materials, principally associated gas, the availability of competitively-priced natural gas liquid (NGLs), proximity to international markets, existing petrochemical technologies, excellent infrastructure, low utility costs and the attractive financing incentives now on offer combine to promote and invigorate the sector.

''The application of the new foreign investment law is a major factor toward the expected growth of the petrochemical industries,'' Al Zamil said.

Under this new investment law, which is being enforced by the Saudi Arabian General Investment Authority (SAGIA), the licensing procedures have been streamlined, tax codes are being revised to promote competitive taxation policies, financing is extended by the Saudi Industrial Development Funds up to 100 per cent to foreign-owned industrial projects, foreign investors are given the option to full ownership of businesses and real estate, and the issuance of visas for foreign investors are now simplified.

The involvement of the Saudi private sector in the petrochemical industry has mainly been in projects such as plastic processing, production of formaldehyde, hexamine and resins.

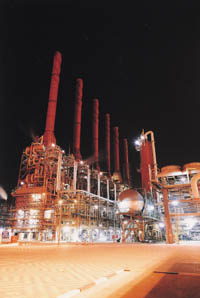

The major players in the local petrochemical industry have not started to come, although Al Zamil said that the entry of the $650 million Saudi Chevron Petrochemical Company, which now produces 480,000 tonnes per year (tpy) of benzene, 220,000 tpy of cyclohexane and 370,000 tpy of gasoline, ''has opened a new dimension in the production of more value-added products.''

When the company came onstream in 1999, it was seen as a defining moment in Saudi Arabia's petrochemical development, proving the confidence in the sector in the Kingdom.

Saudi Chevron is now implementing its second phase, investing further $480 million, to produce a chain of derivatives.

In this new era of plant cooperation, Saudi Chevron provides benzene to Sabic affiliates in Jubail, and this trend is sure to continue with a raft of private ventures in the pipeline. Sabic itself says that it will continue to give high priority to providing raw materials for Saudi downstream industries, particularly in the manufacturing sector.

Feedstocks have been available from Sabic affiliates since the 1980s but only recently has the government fully supported the private sector through the provision of the Saudi Industrial Development Fund (SIDF), firm cooperation from the Royal Commission for Jubail and Yanbu and more competitively-priced feedstocks.

Samsung Engineering has signed a $350 million turnkey contract to build two new petrochemical plants for the Kingdom's Saudi Polyolefins Company.

Saudi Polyolefins Company is owned 75 per cent by Saudi Arabia's National Petrochemical Industrialisation Company (NPIC) and 25 per cent by Basell Holding Middle East GmbH (itself a joint venture between Germany's BASF and Royal Dutch/Shell.

The project will consist of a 450,000 tpy polypropylene plant and a 275,000 tpy drying unit for processing propane into propylene.

Saudi Polyolefins Company is now buying a share in an existing Sabic pipeline supplying propane feedstock from Ju'aymah on the coast to Jubail-based Sabic affiliate Petrokemya.

Also in Jubail, The Industrial Projects Development & Management Co. Ltd is said to be working on the design plans and other related initial processes for the establishment of six new petrochemical plants at a total cost of approximately SR1 billion ($267 million).

Sabic and Saudi Aramco are said to have agreed to supply some of the feedstocks for the facilities, Sabic providing ethylene and methanol from neighbouring affiliates.

The company will produce 100,000 tpy of ethylene oxide, 150,000 tpy of ethanol oxide and 50,000 tpy of methylamine. Construction will start in mid-2003 with production expected to begin in the second half of 2005.

The plants will, according to a company official, use the latest in operational and management technologies. Most of the production will be exported to Europe and Asia and the plants are expected to assist the transfer of technology to the Kingdom through trained Saudi manpower.

Jubail United Petrochemical Company (JUPC) is building a $350 million ethylene plant.

Japan's Toyo Engineering is the main contractor at the 400,000 tpy high density polyethylene (HDPE) facility, which will use Union Carbide's Unipol technology and will be downstream of a one million tpy cracker which will also produce ethylene glycol and linear alpha olefins.

Meanwhile, the Saudi International Petrochemical Company (SIPC) is said to have conducted feasibility studies on the third phase of a petrochemical complex at Jubail.

The first phase involves the construction of a 50,000 tpy butanediol and maleic anhydride plant and a one million tpy methanol plant.

The second phase will see the construction of an acetic acid plant with a capacity of 275,000 tpy and a vinyl acetate monomer plant with a capacity of 250,000 tpy. A company official has said that the SIPC will select a technology supplier for the acetic acid plant towards the end of this year, with the project moving forward in the first quarter of next year. Basic engineering for the vinyl acetate facility was completed earlier this year, according to reports.

Over on the West coast of Saudi Arabia at Yanbu, Gulf Petroproducts is said to have picked the site for its planned n-paraffin and linear alkyl benzene plants.

The paraffin plant will have a 100,000 tpy capacity while the linear alkyl benzene facility will have an 80,000 tpy capacity.

Also in Yanbu, Tecnimont earlier this year won a contract from Xenel Industries for a polypropylene project. The expected start up date for the 280,000 tpy project is September 2004, reports said.

Sabic will surely play an even greater role in the development of private petrochemical schemes in Saudi Arabia, be it from ex-Sabic staff being employed by the private sector or the impact on Sabic feedstock costs by competition from the multi-billion dollar Saudi gas initiative.

However, some analysts are warning that the positive effects of private development could be blunted should there be any duplication of projects and the products they manufacture.