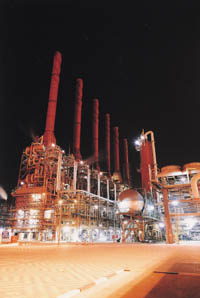

Petrokemya ... 800,000 tpy polyethylene plant being built

Petrokemya ... 800,000 tpy polyethylene plant being built

Testimony to Sabic's pioneering R&T role in the global industrial landscape was the launch last month of a new technology developed by Sabic and leading German engineering company Linde AG.

The technology (termed alpha-Sablin) for the production of Linear Alpha Olefins (LAOs), uses ethylene as feedstock for a one stage homogenous reaction for the production of C4-C20+LAO.

The LAOs produced in the alpha-Sablin reactor are fed to a series of conventional separation columns to obtain the desired cuts with the required quality specifications.

For this new process, the high selectivity one-stage reactor produces high purity products that do not require the installation of any product polishing steps such as super-fractionation distillation towers for removal of side products, according to Sabic.

The process uses a Single-Stage reactor which requires fewer plant components, and therefore needs less capital and operating costs compared to other processes.

The process also operates at low reaction temperature and pressure, implying that the equipment required for the process is less expensive and safer to operate.

The process also offers a highly flexible product slate, according to Sabic. For example, based on market demands, the process parameters can be adjusted to maximise the production of light or heavy cut LAOs.

The development of alpha-Sablin was achieved through an extensive joint research and development programme launched in 1994 by the two technology partners using different bench scale reactors as well as pilot plants built at Sabic's R&T site in Riyadh to demonstrate and optimise the technology.

The technology is seen by Sabic vice chairman and managing director Mohamed Al Mady as the latest breakthrough for the Corporation's R&T arm, which has produced more than half a dozen developments over the last five years.

''The investment we are making in this area is starting to pay dividends and follows hot on the heels of the pioneering acetic acid technology announced last year,'' he said.

By exploring new technologies and carrying them into commercial production, Sabic is fulfilling its role in boosting the Saudi economy, said Al Mady, adding that LAO production would provide a good opportunity for development of the downstream detergent and additive industries, so diversifying the economy further.

Sabic R&T executive vice president Dr Abdulrahman Al Ubaid explained that alpha-Sablin technology possessed many features such as a low investment and production costs in addition to product distribution flexibility.

Based on market demands, the process parameters can be adjusted to maximise the production of light or heavy LAOs.

Sabic will build the first plant of its kind using the technology to produce 150,000 tonnes per year of LAO at its new wholly owned affiliate - UNITED (The United Petrochemical Company) in Jubail.

The company is the 17th Sabic affiliate in the Kingdom and is expected to come onstream in the first half of 2004, according to the Corporation.

Besides LAO production, UNITED will accommodate major ethylene and ethylene glycol (EG) plants.

A new 800,000 tpy polyethylene plant is also being built at neighbouring Petrokemya, and the new technology will be licensed to potential producers by both partners.

LAOs have a variety of applications. Light cuts such as Butene-1, Hexane-1 and Octene-1 are used as comonomers in the production of linear low-density polyethylene (LLDPE). Medium cuts such as Decene-1, Dodecene-1 and Tetradecene-1 are used for synthetic oil, detergents and shampoos.

Heavy cuts, Hexadecene-1, Octadecene-1 and Eicosene-1 are used in lube oil additives, surfactants, oilfield chemicals and wax product applications.