Waleed Qattan

Waleed Qattan

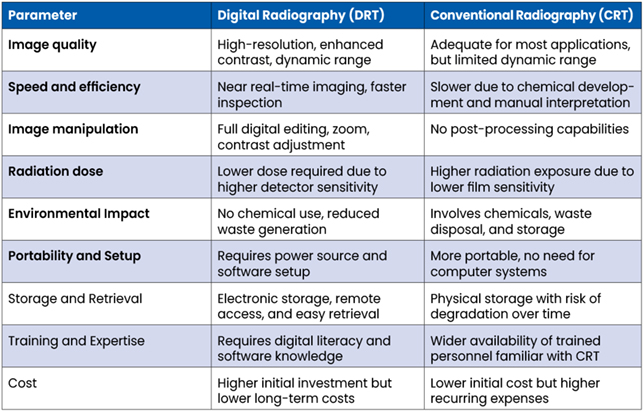

Both DRT and CRT have their respective strengths and limitations, making them suitable for different applications and contexts, writes Waleed Qattan, Project Engineer, Tanajib Gas Plant Projects Department

Adiographic testing plays a vital role in ensuring the structural integrity and safety of critical components across a wide range of industries, including oil and gas, aerospace, construction, and manufacturing.

As a non-destructive evaluation method, it enables the detection of internal imperfections such as cracks, porosity, inclusions, and lack of fusion in materials such as welds, castings, and composite structures.

Over the years, industrial radiographic techniques have evolved significantly, and two dominant approaches have emerged: Industrial digital radiography (DRT) and industrial conventional radiography (CRT).

|

The DR systems Scanray DRT Field Kit (unpacked) |

While both techniques utilise ionising radiation, typically X-rays or gamma rays, to penetrate the test object and produce images of its internal structure, they differ fundamentally in terms of imaging technology, processing workflows, and environmental considerations.

This paper presents a comparative analysis of these two radiographic methods, focusing on their technical characteristics, operational advantages, and suitability for various industrial applications.

INDUSTRIAL DIGITAL RADIOGRAPHY (DRT)

DRT is a modern, filmless imaging technique that utilises digital detectors, such as flat-panel detectors or phosphor plates, to capture and convert X-ray or gamma-ray radiation into digital images.

These images are displayed in near real-time on computer monitors, allowing for immediate interpretation and analysis.

The process typically involves the following steps:

1. Positioning of the digital detector behind the test object.

2. Exposure to X-ray or gamma radiation.

|

DR-system-1025F-Flexible-DRT-panel-6-inch-pipe-to-elbow |

3. Conversion of the radiation into a digital signal by the detector.

4. Processing and display of the image using specialised software.

The key advantages of a DRT include:

• Real-time imaging: One of the most significant benefits of DRT is its ability to provide immediate imaging results, enabling faster decision-making and reducing inspection cycle times.

• High image quality: DRT systems typically offer superior image resolution, contrast, and dynamic range compared to conventional methods, allowing for the detection of finer defects and anomalies.

• Digital manipulation: Images can be digitally enhanced, magnified, and filtered to improve defect visibility and interpretation accuracy. This flexibility enhances the reliability of inspections.

|

DR system 1025F Flexible DRT panel (36-inch pipe to flange) |

• Reduced radiation exposure: Digital detectors are more sensitive to radiation, allowing for the use of lower exposure levels while maintaining image quality. This contributes to improved safety for operators and reduced radiation risk to materials.

• Efficient data management: Digital images are stored electronically, eliminating the need for physical film storage. This allows for seamless archiving, remote access, and easy sharing of data across teams and locations.

• Environmental benefits: The elimination of chemical processing and film development significantly reduces hazardous waste and supports sustainability initiatives.

There are, however, some limitations of the DRT. These include:

|

DR system Xpress-Scan Automated DRT cross country pipeline solution (DWSI technique) |

• Higher initial cost: DRT systems typically require a higher initial investment compared to CRT systems due to the cost of digital detectors, software, and associated infrastructure.

• Technical expertise: Successful implementation of DRT requires trained personnel capable of operating sophisticated equipment and interpreting digital images effectively.

INDUSTRIAL CONVENTIONAL RADIOGRAPHY (CRT)

CRT is the traditional method of industrial radiographic testing and has been in use for many decades. It involves the use of X-ray film, which is placed behind the object under inspection.

Upon exposure to radiation, the film captures an image of the internal structure, which is then chemically developed in a darkroom to produce a visible radiograph.

The main advantages of a CRT include:

|

A-comparative-analysis-of-the-DRT-CRT-techniques |

• Lower initial investment: The equipment required for CRT is generally less expensive than that for DRT, making it more accessible for smaller operations or projects with limited budgets.

• Larger coverage area: CRT films can be manufactured in larger sizes, allowing for a single exposure to cover extensive areas of the test object, which can be beneficial in certain applications.

• Proven expertise: The widespread use of CRT has resulted in a large pool of trained and certified technicians, ensuring ease of implementation and interpretation.

Similar to the DRT, the CRT technique too has some limitations:

|

DR systems Scanray DRT Field Kit |

• Chemical dependency: CRT involves the use of hazardous chemicals for film development, posing environmental and health risks. Waste management and disposal of these chemicals also add to the operational complexity and cost.

• Image deterioration: Physical films can degrade over time due to improper storage conditions such as temperature and humidity fluctuations, potentially compromising data integrity.

• Limited image manipulation: Once developed, the film offers limited scope for enhancement or adjustment, making it challenging to detect subtle defects without retaking the image.

EVALUATION BASED ON OPERATIONAL NEEDS

Both DRT and CRT have their respective strengths and limitations, making them suitable for different applications and contexts.

|

DR system Xpress-Scan Automated DRT kit installation |

DRT offers significant advantages in terms of speed, image quality, environmental impact, and data management, making it the preferred choice for industries requiring high precision, rapid turnaround, and digital integration.

On the other hand, CRT remains a viable option for applications where cost, simplicity, and extensive technician familiarity are key considerations.

As industries continue to embrace digital transformation and sustainability, the adoption of DRT is expected to grow, particularly in sectors such as oil and gas, aerospace, and advanced manufacturing.

However, the transition from CRT to DRT should be carefully evaluated based on operational needs, budget, and long-term strategic goals.

Ultimately, the choice between DRT and CRT depends on a variety of factors, including inspection requirements, resource availability, and environmental considerations.

Understanding these differences allows organisations to implement the most effective and efficient radiographic testing solution for their specific use case.

|

DR systems Scanray 1230 with small boar bracket (customised solution) |