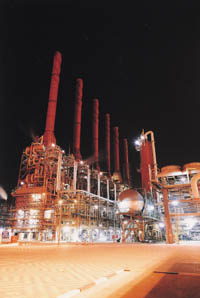

Above and right ... facilities in the MGS are being expanded

Above and right ... facilities in the MGS are being expanded

AS MANY of the world's leading oil and gas companies prepare to invest in multibillion dollar gas initiatives in Saudi Arabia, Sabic is optimistically preparing to reap the benefits of what should be abundant new feedstock supplies.

Incremental gas from the projects will be used for petrochemical production, power plants and for water desalination, and it seems almost certain that Sabic will be involved in some aspects of the initiative.

Availability of feedstock has long been a key factor in the development of downstream industry in Saudi Arabia, particularly at Jubail and Yanbu.

State oil company Saudi Aramco has, since the 1970s, recovered its associated gas reserves through the Master Gas System (MGS), which is currently being expanded.

Today, major processing facilities at Berri, Shedgum, 'Uthmaniyah and, shortly, Hawiyah, treat the gas from Saudi Aramco gasfields and recover natural gas liquids.

Gas from the plants is then supplied to the sales gas distribution grid, with the NGLs being supplied to downstream fractionation plants at Ju'aymah and Yanbu. It is these downstream facilities which supply petrochemical feedstock and liquid petroleum gas (LPG) for export and industrial consumption.

However, meeting demand for sales gas from industrial and power generation sectors has required several major expansions to MGS infrastructure in recent years.

The Shedgum Gas Plant has increased its processing capacity by 20 per cent to 2.4 billion cu ft per day following a major debottlenecking project earlier this year, following debottlenecking projects at Berri and 'Uthmaniyah.

A new, $1.4 billion Gas Plant at Hawiyah has been under construction since 1999 and is expected to be completed by next month.

The facility, which will be the largest gas plant in the MGS, will produce 1.4 billion cu ft per day of non-associated gas. It will receive sweet gas from the Jauf reservoir and sour Khuff gas from wells in the Hawiyah and Haradh fields. It will be the first MGS plant to process only non-associated gas.

With its commissioning, the Hawiyah plant will boost total supply to the MGS by some 35 per cent to around 5.6 billion cu ft per day.

Site preparation also started earlier this year for the 1.4 billion cu ft per day capacity Haradh Gas Plant, which is scheduled to begin production in December 2003.

Japan's JGC will build the estimated $410 million plant under a turnkey contract, with Consolidated Contractors International Company (CCC) Saudi Arabia as a subcontractor.

Saudi Arabia's proven reserves of associated and non-associated gas are estimated at approximately 210 trillion cu ft, with new discoveries under the gas initiative likely to increase that figure significantly. Estimates also suggest that domestic demand in the Kingdom for gas will rise to 6.8 billion cu ft per day in 2005, and up to 8.2 billion cu ft per day by 2012.

The Kingdom's petrochemical sector will be a leading consumer of the additional gas supplies which will come onstream with the expansions to the MGS and the new gas developments to be undertaken by the international majors.

Steps are now being taken to ensure that new gas supplies reach the industrial cities of Jubail and Yanbu.

As part of the expansion of natural gas distribution within Saudi Arabia, work started earlier this year on a 1,200 km gas pipeline from Shedgum in the Eastern Province to Yanbu, on the West coast.

The pipeline will have an initial capacity of about 300 million cu ft per day, which could be increased to one billion cu ft per day if required.

The project is likely to be completed by the end of 2003, according to officials.

The pipeline will parallel another pipeline carrying oil from East to West, and will also run parallel to the natural liquid gas pipeline.

The availability of gas in Yanbu will release a large quantity of ethane, which is currently used as fuel, so that it can be utilised as feedstock for petrochemical factories and the fuel needs of new industrial projects, reports suggest. Gas is currently planned for use in three new industrial projects in Yanbu.