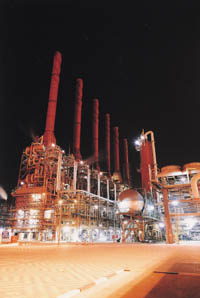

Ibn Rushd is receiving finance in a bid to achieve its strategic corporate goals

Ibn Rushd is receiving finance in a bid to achieve its strategic corporate goals

Ibn Rushd finance Saudi Arabia's Public Investment Fund has decided to finance Sabic affiliate Ibn Rushd to the tune of SR4 billion ($1.06 billion), according to reports.

This sum is intended to replace $850 million in loans extended by commercial banks in the past few years to Ibn Rushd, and to finance the expansion of its polyester plant to the tune of SR1 billion.

Ibn Rushd was established in 1993 as a joint stock Saudi company in Yanbu with a capital of about SR2.5 billion. The capital is 48 per cent held by Sabic, with the remaining shares held by a number of local, Gulf and Arab shareholding companies.

The new loan is expected to enable Ibn Rushd to implement its strategic goals, with the objective of becoming a pioneering company in the field of polyester and organic compounds production.

The finance agreement comes after the company announced a net loss of SR76.5 million for the first half of this year, compared with a net loss of SR66.8 million for the same period of last year.

It also comes as Ibn Rushd plans a new acetic acid unit at its Yanbu facility. The estimated $85 million plant is expected to feed the company's purified terepthalic acid (PTA) facility.

Ibn Rushd's current output of aromatics, PTA, polyester textile chips, textile staple, bottle grade chips and carpet staple provides feedstock for other processing industries in the Kingdom.

Ibn Rushd shareholder Hasa Company recently launched a textile project using raw material from Ibn Rushd.

Ibn Rushd started polyester production in 1995 with an annual capacity of more than 140,000 tonnes. The facility operates to the highest international standards, forms a solid base for national processing industries and is seen as providing unlimited investment opportunities in the fields of spinning, weaving, textiles, wrapping and packing materials industries.

Ibn Rushd's PTA facility has an annual capacity of more than 350,000 tonnes. The company also produces 730,000 tpy of aromatics.

The company also has 350,000 tpy benzene and 400,000 tpy paraxylene production capacities. Using the Cyclar process based on propane feedstock, these facilities have been shut for much of this year as the benzene output had not achieved full specifications for Sadaf's styrene monomer plants. As a result, Sadaf had been procuring its benzene feedstock from Iran and other Middle East sources through long-term contracts.

The Ibn Rushd complex stands out as a symbol of complementation between Sabic and the private sector which is seen as a model for industrial integration in the field of basic industries.