Rigid Application of quality control is a feature of every aspect of APC's manufacturing operations, and a comprehensive programme of implementing quality systems has been in place since the company was established.

Products of the highest quality are fundamental to APC's operations, and the company possesses certificates from the American Petroleum Institute (API) and APIQR (American Petroleum Institute Quality Registrar) and ISO9001.

Under the API monogram, APC has been manufacturing Plain End Line Pipes (5L) and Casing Pipes (5CT) since 1996 for leading oil and gas companies throughout the Middle East.

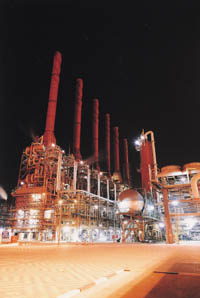

The company's Riyadh ERW mill utilises the latest test and inspection facilities providing customers with a product of uniform quality. APC also operates a strict company-wide total Quality Assurance Programme.

This programme is implemented from initial procurement of the raw material through the processing phase and up to final shipment of the goods.

Under such a programme, APC is able to ensure that all delivered products can be used with confidence.

The company's Quality Control section ensures that all aspects of pipe manufacture are within specified and acceptable international tolerances.

The principal inspection and tests undertaken by the Quality Control section of the company include chemical and physical analysis; tensile strength testing; dimensional inspection; ultrasonic inspection; hydrostatic testing; deformity testing and hardness testing.

Frequent physical tests are also applied after welding to determine overall pipe resilience. Equal emphasis is also placed on other aspects of pipe testing and inspection.