Ar Razi ... considering new methanol plant

Ar Razi ... considering new methanol plant

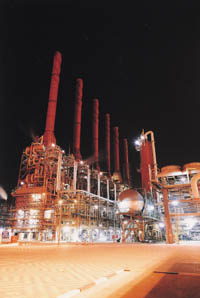

CAPACITY INCREASES at Sabic affiliates in Jubail and Yanbu continue to make their mark on the industrial landscape of Saudi Arabia.

And as such Sabic continues to provide the impetus for the Kingdom's drive to diversify sources of income.

The non-oil industrial sector in Saudi Arabia now accounts for more than 65 per cent of the country's Gross Domestic Product (GDP), and this figure should grow as the latest batch of expansions come onstream.

Sabic's annual production capacity is approximately 36 million tonnes per year (tpy). By 2010, this figure is expected to have risen to approximately 48 million tpy.

The Corporation will establish its 17th manufacturing affiliate in the Kingdom in Jubail when it commissions the $2 billion Jubail United Petrochemical Company (JUPC) plant in 2004.

The olefins complex, a 100 per cent Sabic subsidiary, will comprise ethylene, ethylene glycol and alpha olefins units with a total ethane cracking capacity of up to one million tpy, 460,000 tpy of ethylene glycol and 100,000 tpy of alpha olefins.

US-based Fluor Daniel is the project management services contractor for the project, drawing up the front end engineering and design package, while another US firm, Scientific Design has been appointed as the technology supplier for the ethylene glycol unit.

JUPC will also provide the feedstock for a new 400,000 tpy polyethylene plant being planned at another Sabic affiliate, Petrokemya.

Petrokemya awarded the turnkey contract to build the new plant to Japan's Toyo Engineering, while the facility will use Union Carbide technology.

Another Jubail-based affiliate, Ar Razi, is said to be studying plans for a fifth, $250 million, 850,000 tpy methanol plant. If sanctioned, the plant would take Ar Razi's methanol capacity to 3.85 million tpy. Ar Razi is a 50:50 joint venture between a Mitsubishi Gas Chemical consortium and Sabic.

Ar Razi is already the largest single-complex methanol producer in the world, representing approximately 10 per cent of global output. Its fourth methanol plant was commissioned in September 1999.

Sabic brought a number of expansion projects onstream last year and earlier this year, some of which created new milestones for the Corporation.

Sharq brought a new 450,000 tpy ethylene glycol plant onstream while debottlenecking its polyethylene plant to increase production by 300,000 tpy to 750,000 tpy. With the new ethylene glycol plant, Sharq became the world's largest single-complex producer.

Petrokemya brought its Olefins III project onstream late last year, consisting of an 800,000 tpy flexible feedstock ethylene plant, a 160,000 tpy propylene plant and a 25,000 tpy benzene unit.

Kemya, a joint venture between ExxonMobil and Sabic, completed a $1 billion expansion of its complex earlier this year.

A 700,000 tpy ethylene plant, using technology supplied by ABB Lummus Global, was brought onstream recently, following the addition at the plant of 235,000 tpy linear low density polyethylene, 218,000 tpy low density polyethylene, and 200,000 tpy propylene facilities.

Sadaf added a second styrene monomer plant last year, adding 500,000 tpy to the company's capacity, bringing the total capacity to 950,000 tpy. The new plant is a 50:50 joint venture between Sadaf and Petrokemya.

These expansions reinforce Sabic's role as a world class business.

The Corporation was established in 1976 to transform methane, ethane and other natural gases into chemical and petrochemical products with countless applications in modern life.

Today, the Corporation's range of products includes basic and intermediate chemicals, polymer resins and polyester, fertilisers, metals, and industrial gases.

Its basic chemicals portfolio includes olefins, aromatics and oxygenates, and intermediates products include methanol, methyl tertiary butyl ether (MTBE), ethylene, ethylene glycol, ethylene dichloride, styrene vinyl chloride monomer, industrial ethanol, butene-1, caustic soda and sulphuric acid. Chemicals production accounts for more than 50 per cent of total output.

Within the chemicals sector worldwide, Sabic is working to consolidate and extend its reputation for excellence. With a secure supply of feedstocks, it creates an ideal platform to develop its position in selective markets and to increase its downstream diversification.

Sabic's polymers portfolio includes polyethylene, polypropylene, polyvinyl chloride, polystyrene and melamine. These and other products are marketed under the brand name Ladene-Arabic for plastics.

In a highly competitive marketplace, Sabic is one of very few companies in the world to produce all five of the most widely used thermoplastic resins.

These essential polymers - linear low density polyethylene (LLDPE), high density polyethylene (HDPE), polypropylene (PP), polyvinyl chloride (PVC) and polystyrene (PS) - provide the firm foundation for Sabic's comprehensive, integrated polymers and petrochemicals portfolio.

Within Saudi Arabia, Sabic serves more than 350 downstream plastics processing firms.

Most of Sabic's polymer products are manufactured by affiliates throughout the Kingdom: Kemya, Ibn Hayyan, Sharq, Ibn Zahr; Petrokemya and Yanpet.

Sabic's fertiliser industry is one of the largest in the world with a combined total production capacity of more than four million tpy.

The major overseas markets for Sabic fertilisers are in Asia, Africa, Australia, New Zealand and the US.

Of these, the Asian marketplace remains crucial. Four out of the five largest urea consumers in the world-India, Vietnam, the Philippines and China-are located here. Sabic's geographical proximity to these significant importers represents a major competitive advantage.

Indeed, this beneficial geographical location gives it a logistical advantage over many of its competitors.

Strong sales and marketing links also connect it with the US while its proximity to Europe, Southeast Asia and the Pacific Rim allows it to view these key areas as important home markets.

Sabic products account for the bulk of Saudi fertiliser exports, in respect of both ammonia and urea fertilisers. And the Kingdom is now the fifth largest net exporter in the world after Russia, Indonesia, the Netherlands and Canada.