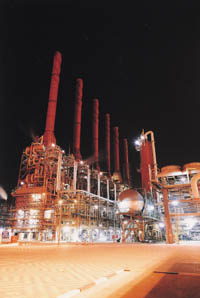

Geyad for Commerce and Import Company (GCI), a joint venture between Al Nasser Industrial Enterprises (ANIE) of the United Arab Emirates, Abdullah M Al Hussaini and Mohammad A Al Botain of Saudi Arabia, has performed prestigious work throughout the Kingdom, especially for Saudi Aramco, Saudi Consolidated Electric Company (SCECO) and major companies in the industrial cities of Jubail and Yanbu.

GCI has undertaken various projects for major clients in the Kingdom.

Examples include the supply of steel structures for the purified terephthalic acid (PTA) project at Arabian Industrial Fibers Company (Ibn Rushd) in Yanbu, the fabrication and delivery of steel structures for the PTA project at Ibn Rushd, the fabrication and delivery of steel structures for the Al Jubail Petrochemical Company (Kemya) low density polyethylene (LDPE) project in Jubail and the manufacturing of major portions of steel structures, ducts and buckstays for SCECO's Ghazlan Power Plant.

GCI has also been registered with Saudi Aramco as an approved vendor for the fabrication of onshore structural steelwork, platforms, gratings, pressure vessels, tanks, pipe spools, pipes and miscellaneous steel structures.

For more than 18 years, Geyad has been providing Saudi Aramco with various fabricated steel structures related to many projects.

To mention a few, GCI has supplied Saudi Aramco with a major portion of structural steel for Shedgum Debottlenecking, Haradh GOSP 1 and the East-West pipeline pump station at Khuyrais.

For Sulayyil Bulk plant of Saudi Aramco, GCI has supplied stop oil storage tank (65,000 litres capacity) and raw water storage tank (38,000 litres capacity), along with diesel generator fuel and kerosene storage tanks.

On a regular basis, the company takes part in various Saudi Aramco projects such as fabrication of pipe spools, pipe sleeve welding and external fusion bonded epoxy coating of pipes.

Geyad's product portfolio falls into five principal categories: shop fabricated pipe spools to ASME/ANSI B31.1, B31,3 and as client requirement; shop fabricated storage tanks (water, chemical and oil) to API 650, API 620, UL-142, ANSI/AWWA D100-84; shop fabricated steel structures to AISC manual for steel construction and British Standard; pressure vessels according to 'U' certificate of authorisation by ASME; and miscellaneous steel to AISC.

In addition, maintenance and repair of pressure vessels are performed according to 'R' and 'NB' certificates and authorised by The National Board of Boiler and Pressure Vessel Inspector (NBBI), USA.

GCI employs qualified engineers who are experienced in the design of steel structures, pressure vessels and tanks to meet customer specifications and international standards. The engineers are supported by a comprehensive design and detailing facility which implements the most updated software programs such as STAAD, PV ELITE, TANK and Auto CAD.

GCI operates strict Quality Assurance and Quality Control procedures for its manufacturing and repairing processes.

These processes include: plate rolling; machining operations; plasma and band-saw cutting; are welding; MIG welding; TIC welding; SAW welding; hydraulic pressing; drilling/ reboring; oxyacetylene cutting; bar cropping and punching; plate shearing and blasting/ painting.

The company is registered with SGS Yarsley International Certification Services Limited for ISO 9002, while Quality Control personnel are qualified and certified to ASNT/Level II and AWS Certified Welding Inspector.

The main operational factory of GCI is located in Dammam's 2nd Industrial City while the head office is in Al Khobar.

GCI is preparing for the future with a new workshop in Dammam's 2nd Industrial City, which is currently under construction and designed to meet the ever-increasing demand from customers.