Ujjal Mukherjee

Ujjal Mukherjee

Digital transformation in downstream energy is essential for operational efficiency and market adaptability, requiring Lummus Digital's hybrid approach that combines industry expertise with advanced data science to overcome legacy challenges and enhance performance, Ujjal Mukherjee, Chief Technology Officer, Lummus Technology, tells OGN

The downstream energy industry, like all other sectors of the energy value chain, is faced with pressure to improve operational efficiency, enhance decision-making, navigate market volatility, and meet evolving regulatory demands all while contributing to the energy transition.

'In this environment, digital transformation has become essential for downstream operators and producers to stay competitive,' Ujjal Mukherjee, Chief Technology Officer, Lummus Technology, tells OGN energy magazine.

However, he says, implementing digital solutions presents unique challenges.

Legacy systems, fragmented data, and the complexity of refineries and petrochemical plants make adopting new technologies difficult.

This is where a hybrid approach combining deep technical expertise with advanced data science becomes crucial.

DESIGNED FOR SUCCESSFUL OUTCOMES

Lummus Digital (LD), a joint venture between TCG Digital and Lummus Technology, offers products designed with three key objectives and outcomes: Delivering quantifiable and measurable value, addressing specific operational challenges, and leveraging deep process knowledge and expertise.

'Our solutions focus on optimising operations by enhancing yields, improving energy efficiency and accelerating response time. They also emphasise reliability by providing critical insights into equipment and performance and improving turnaround planning,' says Mukherjee, who counts several benefits of partnering with Lummus Digital:

|

Available to Lummus Digital’s clients, the Digital Center of Excellence is an advanced technology training centre that facilitates |

• Clients get access to Lummus and Chevron Lummus Global’s (CLG) a joint venture between Chevron and Lummus proprietary know-how. They get proprietary information imbedded in solutions, and advisory services, tapping into CLG process experts.

• Hybrid models combine the First-principles kinetic model with data science.

• An AI-based data platform (tcgmcube) offers real-time data ingestion and cleansing; scalable, secure, cloud agnostic, on-prem; and low-code analytics for reduced complexity and increased productivity.

• Prebuilt digital solutions provide velocity to value, enabling quick and large returns.

TAILORED SOLUTIONS FOR COMPLEX OPERATIONS

For downstream companies, generic digital tools often fail to meet the specific needs of their operations.

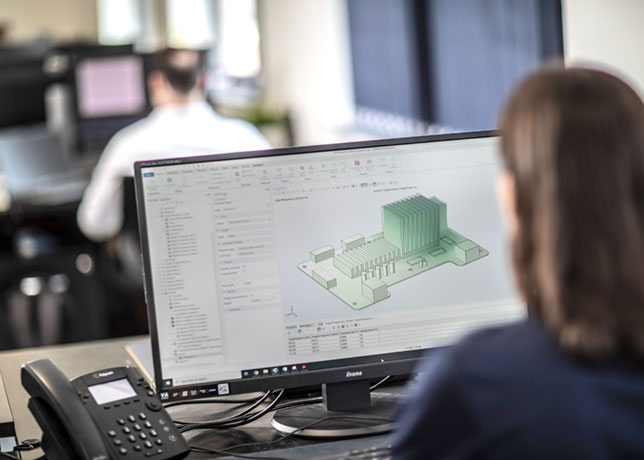

LD’s solutions merge decades of process engineering experience with modern artificial intelligence (AI) and data science.

With over 500 process engineers and more than 100 data scientists, LD provides tailored solutions that solve complex challenges while delivering measurable returns on investment (ROI).

LD’s hybrid model addresses industry-specific issues, offering solutions designed with clear, measurable goals.

In a sector where efficiency and ROI are critical, this approach helps companies enhance operational performance and reduce downtime.

TAILORED & COMPREHENSIVE

The digital transformation in downstream operations often faces obstacles such as legacy systems and siloed data.

LD addresses these challenges with a customised digital roadmap that integrates seamlessly with existing systems.

This tailored approach ensures digitalisation delivers immediate value, improving asset utilisation, decision-making, and minimising operational disruptions.

At the heart of LD’s solutions is a robust big data platform that connects disparate data sources, cleanses information, and makes it accessible for predictive analytics and anomaly detection. LD’s modular solutions allow companies to embark on a gradual digitalisation journey, scaling the adoption based on operational needs.

By centralising data, LD’s platform provides real-time insights and a unified view of performance, helping decision-makers respond quickly to operational demands. This integration helps maintain smooth operations while improving responsiveness to potential disruptions.

EFFECTIVE PROBLEM-SOLVING

LD’s collaboration with subject matter experts (SMEs) is a key factor in its success. Each LD product is developed in close partnership with technology and operations SMEs, ensuring solutions are grounded in real-world expertise.

By blending human expertise with advanced data science, LD anticipates problems and creates predictive models that flag potential issues before they escalate, allowing operators to take preventive action.

LD’s approach doesn’t just solve today’s challenges, it also embeds industry expertise into its tools, making critical knowledge accessible to the next generation of engineers.

Visualisation-based systems offer an intuitive interface for real-time operations while serving as valuable training tools for workforce development.

BRIDGING THE KNOWLEDGE GAP PLUS A MULTIDISCIPLINARY APPROACH

As the downstream workforce undergoes a generational shift, with many experienced engineers retiring, companies face a growing need for effective knowledge transfer.

LD addresses this by embedding essential expertise into its digital tools, ensuring continuity in operations as seasoned professionals exit the workforce.

LD’s tools bridge this knowledge gap, offering intuitive systems that enable younger engineers to access critical information while driving innovation.

These solutions not only improve daily operations but also ensure the long-term development of the workforce.

LD’s solutions address a broad range of challenges across different departments and technologies.

By combining core industry principles with cutting-edge technology, LD offers a comprehensive framework for enhancing everything from process control to energy efficiency.

This multidisciplinary approach allows LD’s solutions to have a widespread impact, improving overall plant efficiency and helping companies stay competitive in an evolving market.

LEVERAGING AI FOR FUTURE PERFORMANCE

Looking ahead, LD is embracing the potential of AI to further enhance operational performance. The company’s use of Generative AI is creating an internal knowledge base focused on operational excellence, augmented by AI agents capable of complex calculations and predictive analytics.

These AI-driven solutions help companies detect anomalies before they occur, offering detailed insights into how to prevent them.

The result is fewer unplanned shutdowns and reduced operational disruptions. LD’s AI tools also quantify the potential economic impact of anomalies, providing companies with the information they need to justify preventive measures and optimise operations.

COMBINATION FORMS FIT-FOR-PURPOSE SOLUTIONS

As the downstream sector adapts to new technological advancements and market realities, LD is combining industry expertise with advanced AI and data science.

LD helps companies overcome the challenges of modern operations, unlocking new levels of efficiency and profitability.

When combined, these capabilities form a hybrid approach with fit-for-purpose solutions that are critical in the digital transformation.