Element exploring AI to help reduce downtime

Element exploring AI to help reduce downtime

Even short periods of downtime can be expensive, with the cost of an hour’s downtime in the oil and gas industry more than doubling in just two years, to almost $500,000

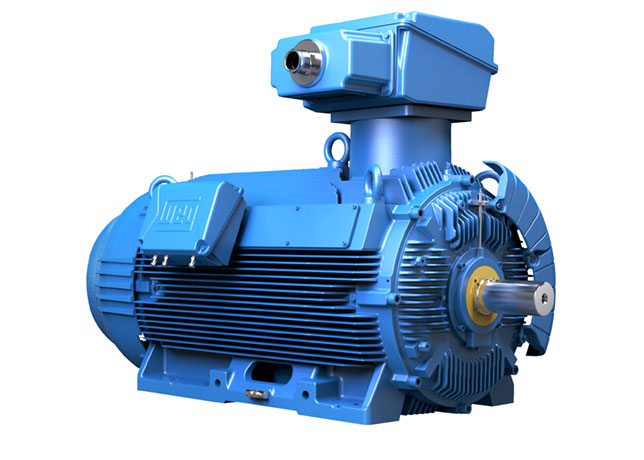

Operators of offshore, refinery and pipeline equipment are being encouraged to adopt new AI technology, which can help reduce time and cost in the general inspection of critical plant and equipment, such as valves, shafts, bearings, pipes, and more.

The callout comes from Element Materials Technology (Element) and its digital engineering division in Singapore, with unplanned downtime now costing companies up to 11 per cent of their yearly turnover.

Even short periods of downtime can be expensive, with the cost of an hour’s downtime in the oil and gas industry more than doubling in just two years, to almost $500,000.

Element is now urging those who look after the maintenance of plant and equipment on offshore platforms, within oil refineries, and in petroleum pipelines, to explore the potential of AI technology to help reduce downtime.

Under its suite of Asset Integrity Management Services (AIMS), the world leader in testing, inspection, and certification (TIC) is using advanced digital cameras and AI to help with facility mapping, layout development for aging plants, and inspection reports on the severity of damaged equipment.

Element’s AIMS suite also provides failure analysis, mathematical modelling, and damage simulation to equipment and structures.

Dr Basab Bhattacharya, Technical Lead for Energy, MEAP at Element Materials Technology, says: 'Singapore is among the most important oil and gas refining hubs in Southeast Asia, and we are committed to supporting businesses throughout the supply chain.

He says: 'The costs of unscheduled downtime can be extremely damaging, however AIMS technology can not only reduce this, but also streamline the entire maintenance process. Our selection of asset integrity management services supports our wider testing and inspection services and enables us to ensure that plant and machinery remains in the optimum operating condition. Any damage or potential failures can be spotted quickly before assets become critically damaged.'

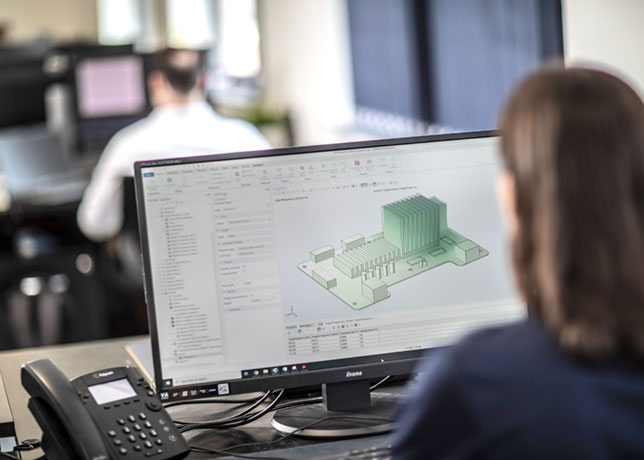

The leveraging of data, mathematics, and digital tools means Element is now able to support oil and gas operators with structural integrity assessments while utilising CAD geometry and materials testing data to deliver high-quality technical insights.

'We are also providing consultations on why components may have failed prematurely. Our experts in our state-of-the-art laboratories and digital engineering teams can interpret the reasons for failures and offer advice on how to prevent the issue from occurring again,' concludes Dr Bhattacharya.