Abdulazez Alshammari

Abdulazez Alshammari

Saudi Aramco researchers Rashid Alrashid, Mahmoud Elzayat, Abdulazez Alshammari explore the use of three robotic machineries in the construction of onshore and offshore hydrocarbon facilities

The construction of an onshore and offshore hydrocarbon facilities is highly complex and comprise significant safety challenges that must be effectively managed.

Thus, the industry has adopted the concept of process automation, which replaces manual tasks with faster and more precise automated systems.

Human-robot interaction theory underlines how important is the dynamic working relationship between humans and robots to enhance both safety and efficiency.

|

Rashid Alrashid |

Research shows that automated construction technologies are advancing rapidly, and that robots can be more accurate and efficient than humans in repetitive tasks.

Robotics and machineries are proven to enhance safety in the industry of construction when compared to humans.

They not only can work in hazardous environments to prevent humans from direct exposure to hazard but can also reduce project schedule and cost.

Integrating process automation usually begins during early stage of project particularly in the planning and design phases, where specific construction activities are selected for automation.

Saudi Aramco executives Rashid Alrashid, Senior Project Engineer, Mahmoud Elzayat, Supervisor Project Engineer, and Abdulazez Alshammari, Project Engineer, in their paper focus on how to integrate the use of three robotic machineries in the construction of oil and gas facilities, namely robotic welding system, drones and underwater robots.

|

Mahmoud Elzayat |

They also emphasise how their utilisation can improve efficiency and safety compared to conventional methods.

ROBOTIC WELDING SYSTEM

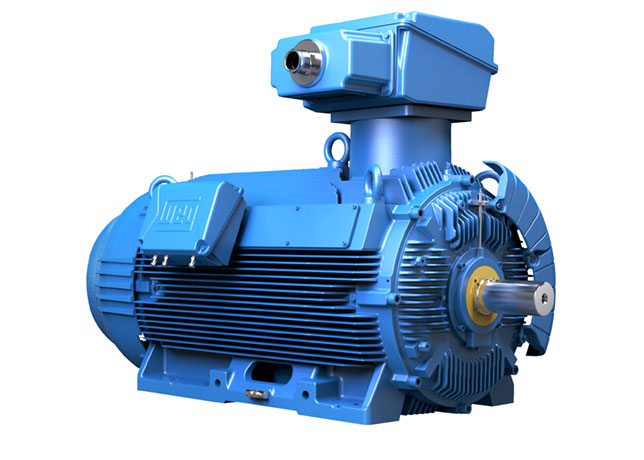

Robotic welding systems have transformed how welding is performed, particularly in large-scale manufacturing and construction.

These systems ensure precision and consistency that would be hard to maintain manually.

Their ability to work without needing rest means they deliver reliable welds according to stringent standards every time.

Advanced features like multi-axis motion and AI-based controls help the system make real-time adjustments, ensuring a high level of quality.

However, despite their impressive efficiency, robotic welders do face limitations. They are great at performing the same task repeatedly but lack the flexibility that humans bring to the table.

Robots can't replicate the intuition or problem-solving skills that a skilled welder might apply to unusual situations.

DRONES

|

Robotic welding systems have transformed welding in large-scale manufacturing and construction |

Drones are widely used in site supervision, mapping, and inspection due to their advanced features.

Equipped with high-definition cameras and sophisticated navigation systems, they can access hard-to-reach areas and provide real-time site information.

Their self-navigation, obstacle avoidance, GPS, and auto flight control systems make site monitoring efficient and precise.

However, like other technologies, drones have limitations. They have restricted travel distances and operating times, and their performance can be affected by adverse weather conditions.

UNDERWATER ROBOTS

Remotely operated underwater vehicles (ROUVs) are primarily used for underwater inspections in offshore construction projects.

These robots are equipped with cameras, sonar systems, and manipulator arms, allowing them to effectively perform inspections and manipulations in aquatic environments.

However, the use of ROUVs comes with certain challenges. Industries are working to address limitations such as restricted operational depth and the reliance on umbilical cables, which can hinder the robots' mobility.

CONCLUSION

|

Drones make site monitoring efficient and precise |

The utilisation of robotics and autonomous machineries is very beneficial in the construction of oil and gas facility. The research concludes that the integration of robotics reduces project timeline and cost in addition to enhancing safety.

But despite the benefits of these technologies, their utilisation arises some challenges such as limited flexibility in robotic systems, short operational time for drones, and restricted mobility for underwater robots. Thus, further research is recommended to evaluate and overcome challenges when adoption these technologies. It is lso suggested to scrutiny broader applications of these technologies across various construction projects in the industry to exploit further potential benefits.

REFERENCES

• Bogue, R (2020). Robots in the offshore oil and gas industries: A review of recent developments. Industrial Robot: The International Journal of Robotics Research and Application, 47(1), 1-6. https://doi.org/10.1108/IR-10-2019-0207 .

• Dzedzickis, A, Subačiūtė-Žemaitienė, J, Šutinys, E, Samukaitė-Bubnienė, U, & Bučinskas, V (2021). Advanced applications of industrial robotics: New trends and possibilities. Applied Sciences, 12(1), 1-25. https://doi.org/10.3390/app12010135.

|

ROUVs can effectively perform inspections and manipulations in aquatic environments |

• Elijah, O, Ling, P A, Rahim, S K A, Geok T K, Arsad, A, Kadir, E A, Abdurrahman, M, Junin, R, Agi, A, & Abdulfatah, M Y (2021). A survey on industry 4.0 for the oil and gas industry: upstream sector. IEEE Access, 9, 144438-144468. https://doi.org/10.1109/ACCESS.2021.3121302.

• Hamela, K, Veeraiah, V, Dhabliya, D, Chellam, V Haliya, Praveenkumar, S, & Sindhwani, N (2024). Role of human-robot interaction in building automated mixed palletization based on industrial applications. In N Sindhwani et al. (Eds.), Robotics and automation in industry 4.0 (pp. 46-64). CRC Press.

• Lincy, S Haliya B T (2024). Artificial intelligence (AI) driven industrial automation. In P Rai et al (Eds), Industry automation: The technologies, platforms and use cases (pp. 85-100). River Publishers.

• Wanasinghe, T R, Gosine, R G, De Silva, O, Mann, G K, James, L A, & Warrian, P (2020). Unmanned aerial systems for the oil and gas industry: Overview, applications, and challenges. IEEE Access, 8, 166980-166997. https://doi.org/10.1109/ACCESS.2020.3020593.

By Abdulaziz Khattak