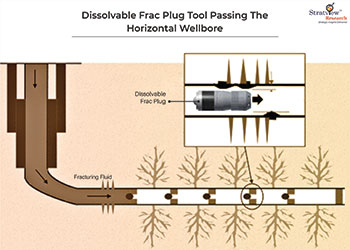

Figure 1 … working of dissolvable frac plugs

Figure 1 … working of dissolvable frac plugs

Dissolvable frac plugs function exactly like conventional frac plugs, but with clear benefits over the latter, including faster production, reduced expenditure, longer laterals, and significant reduction in greenhouse gas emissions, Chandana Patnaik, Technical Writer, Stratview Research, tells OGN

Frac plugs play a vital role in the hydraulic fracking process for any oil and gas field.

Hydraulic fracking is a well-stimulation technique that involves fracturing of bedrock structures by pressurised liquids to increase production of the wells.

US crude oil production from hydraulic fracking leapfrogged from 8 per cent in 2005 to a whopping 65 per cent in 2021.

In this process, frac plugs serve as check valves to provide wellbore zonal isolation allowing the flow of fluids from below their surface to aid in well clean up once the stimulation process is completed.

Frac plugs, initially manufactured using cast iron took a long time for milling-out process. To speed-up this process, composite frac plugs were developed.

Owing to their lightweight, composite frac plugs also enabled the frac plugs to run into a horizontal wellbore. These plugs became the talk of the town in no time.

With the time, the lateral length of the wells also has been growing rapidly

Effective milling operations in the extended-reach laterals of the horizontal wells is a challenge for composite frac plugs as it is hard for these plugs to set their foot on the farthest rock bottom of these wells.

To serve the market better and plug such concerns, came the advent of ‘dissolvable frac plugs’.

As the name suggests, a dissolvable plug uses biodegradable components that would dissolve and leave almost no residue unlike traditional, composite plugs to isolate zones.

Because of the requirements of self-dissolution, high mechanical strength, and being lightweight, the dissolvable frac plugs are made of components like Magnesium (Mg) alloys, and polyglycolic acid (PGA).

PGA is a recent addition to the plastics industry that stands out from other polymers due to its features.

It is an industrial plastic with mechanical characteristics that are at par with other polymers. Its primary characteristics include biodegradability, high strength and toughness, high scratch/cut resistance, and easy processing.

However, PGA is new to the dissolvable frac plug industry and is not being currently of interest to a few major players.

Mg alloys are the materials of choice because of several desirable properties such as reliable dissolution rate at different temperature and pressure brine, high toughness, strength, and hardness.

Table 1 show a few differences between these two components used in manufacturing dissolvable frac plugs.

|

The dissolvable frac plug functions exactly like a conventional frac plug. It can be placed anywhere in the wellbore to isolate certain zones.

The high-strength metal used in the dissolvable frac plug totally breaks down in wellbore fluids leaving almost no signs or residue.

The benefits of dissolvable frac plugs include:

Faster production: These plugs eliminate the need of drilling out the plugs as they dissolve, allowing operators to produce much sooner.

Reduced expenditure: Unlike traditional frac plugs, the dissolvable frac plugs require a lower-cost clean-up run to remove residual proppant from the wellbore. This saves thousands of litres of diesel that is used during the coiled tubing (CT) milling, in addition to saving time and manpower as well.

Longer laterals: No major milling equals no length restrictions related to coiled tubing reach, which means longer laterals and more scope of production.

Significant reduction in greenhouse gas emissions: The lifecycle carbon footprint of the dissolvable plug is estimated to be 91 per cent lesser per wellbore than the conventional plug (Figure 2).

Table 2 below shows some instances where operators using dissolvable frac plugs achieved savings:

Due to their unique value proposition, the adoption of dissolvable frac plugs is rising at an impressive rate.

The global demand for dissolvable frac plugs is estimated to witness excellent progress, growing annually at over 20 per cent rate and crossing $1.2 billion by 2028.

HORIZONTAL WELLS PUSHING DEMAND FOR DISSOLVABLE FRAC PLUGS

A well’s horizontal portion, or the lateral length, is a key factor in well productivity. And lateral lengths have grown incessantly over the years, to serve the growing demand for oil and gas.

|

Figure 3 depicts the rapid growth in the lateral length of the Permian Basin, which accounts for more than 40 per cent of the US crude oil production and 17 per cent of US natural gas production.

When drilling becomes difficult with vertical wells due to reasons like reservoir's structure, the horizontal approach (a multi-directional drilling technique) is employed as an alternative, as one can reach long lateral areas of the wells.

The increasing use of horizontal wells in parallel increases the demand for dissolvable frac plugs.

FUTURE OF DISSOLVABLE FRAC PLUGS

Dissolvable technology is catching up in a field that never lacks challenges. It is now a common aspect of well completions that works especially and effectively in lengthy laterals with higher stage density.

|

Figure 2 … the carbon footprint of 70-plug deployment in metric ton Co2eq |

The demand for dissolvable frac plugs is growing simultaneously with the increasing rig count, demand for oil and gas, share of horizontal wells, etc.

The worldwide rig count has started recovering. As of September 2022, the global rig count grew from 1,448 (in Sept 2021) to over 1,853. Across the globe, the US hosts nearly 40 per cent of the oil and gas rigs.

While a few aspects of milling, and other operations are improving to meet the challenging demands, there are some potholes in the way.

The extra cost paid for dissolvable plugs can be a burden in the beginning. The initial cost of these dissolvable plugs is 5-10 times than that of composite plugs.

However, the extent of savings in terms of time, manpower and consumables makes up much more than the initial cost. Additionally, they are more environment-friendly as compared to the rivals.

The plethora of benefits along with growing awareness will lead to the rising penetration of dissolvable frac plugs, thereby creating a skyrocketing demand in the coming decade.