Gas Injection Platform (GIP) for ADMA-OPCO by NPCC

Gas Injection Platform (GIP) for ADMA-OPCO by NPCC

The instal-lation of Zakum Gas Injection Platform (GIP) earlier this year marked yet another record for NPCC.

A major milestone was reached on this project with the safe and successful loadout and installation of the 4,100 tonne integrated deck, utilising the 'floatover' installation method.

The 'floatover' method involves positioning the deck over a pre-installed jacket and then slowly lowering/stabbing it into the jacket legs by ballasting the cargo barge (carrying the structure) with approximately 14,000 tonnes of water and then retrieving the cargo barge from under the installed deck.

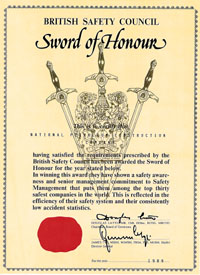

The fabrication of this six-leg deck and its associated structures required more than one million manhours, and met the highest standards of safety, quality and housekeeping throughout the 14 month fabrication period.

The critical operations included:

These efforts resulted in the load out of the deck taking just five hours, while the installation required only 28 hours from the sail away of the deck until the safe return of the barge to base. These were record times for both operations.

NPCC attributed the success of the project to good cooperation between NPCC, the managing engineer (Technip) and client (Adma-Opco), whose active participation in the several risk assessments augmented NPCC's own HSE efforts.