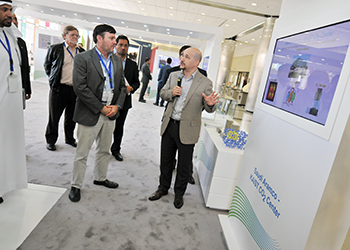

Kaust ... leading the path in technology

Kaust ... leading the path in technology

Aramco is planning anchor projects such as the Ras Al Khair Maritime Yard to kick-start the creation of entire industries through single, major development projects

Saudi Aramco’s commitment to create more value in everything it does underlines its drive to go beyond simply generating revenue. It forms the lens through which Aramco evaluates its commercial endeavours for opportunities to generate value beyond its immediate business objectives.

It impels the company to capitalise on the potential multiplier effects of its investments and projects to promote sustainable economic development that fosters an energy efficient society, high-value job creation, and diversification.

Energy efficiency is an imperative for prosperity in today’s world. As steward of the nation’s energy resources, Aramco has an obligation to promote the wise and responsible use of energy.

Aramco supports the nation’s commitment to a sustainable energy economy by championing best practices in conservation and efficiency. Aramco believes energy is opportunity. Aramco therefore has a responsibility to combine its core competencies with the energy of its resources, its people, and its ideas to create the conditions for mutual benefit.

By using its business activities as launch pads for the further development of the kingdom and its citizens, Aramco can help enable a healthy and dynamic economic ecosystem where all can thrive. One way Aramco magnifies the effect of its commercial operations is by accelerating the growth of a globally competitive Saudi energy services sector.

This will be accomplished by using a two-pronged approach. Aramco is planning anchor projects such as the Ras Al Khair Maritime Yard to kick-start the creation of entire industries through single, major development projects with key partners. Second, through the use of incentives and other measures of broad-based support, Aramco works to increase the overall competitiveness of targeted energy-related sectors. Sometimes seemingly small changes can pay huge dividends in the quest to find solutions for limiting impacts on the environment. One such example is its campaign to replace less efficient incandescent lights in its facilities, offices, and communities in favour of environment-friendly LED lighting.

Over the last two years, Aramco upgraded lighting in 18,000 homes and 200 office buildings, installing more than 550,000 LED light bulbs. Aramco is well over halfway to attaining its goal of replacing 14,500 street lights with LED fixtures, and by the end of 2016 it plans to replace a total of 60,000 fluorescent lights with LED lamps, says Aramco in its Annual Review for 2015.

The LED lights installed thus far are estimated to produce annual energy savings in excess of 42 gigawatt hours, equal to saving more than 80,000 barrels of oil equivalent per year, resulting in a reduction in CO2 emissions of more than 31,000 metric tonnes.

Installing LED lighting is just one facet of its Lead by Example initiative for improving energy efficiency, which strives for a 35 per cent reduction of total energy use in its buildings, transportation, and communities by 2020. Its other impact priorities for energy efficiency and sustainability include the use of high-efficiency cooling and heating systems with smart meters in its residential homes and industrial buildings, and the implementation of new fuel efficiency standards in its vehicle fleet, which alone is estimated to provide a total annual savings of 40,000 barrels of oil equivalent.

By improving its own energy efficiency, Aramco creates a model for others to follow. The shift to an energy efficiency culture within the company and in the kingdom is at the core of Aramco’s commitment to build a sustainable energy economy. Aramco’s progress during 2015 contributed to its goal of increasing the level of locally produced materials and services Aramco procures to 70 per cent by 2021.

The drive to support the domestic energy sector has the potential to create thousands of new direct and indirect jobs and establish the kingdom as a hub for the provision of engineering and oilfield services, as well as the manufacturing of critical and everyday supplies. Further downstream, Aramco sees its expanding chemicals business as a driver of economic diversification. Not only will its chemicals complexes provide prospects for skilled employment, but the associated conversion parks will attract new manufacturing and support service industries that will stimulate even more employment and business opportunities.

In anticipation of the demand for skilled employees, Aramco is partnering with local businesses and government agencies to build training institutes to empower the Saudi workforce to take advantage of, and thrive, in the jobs of the future.

Aramco does not consider its business to be an either-or proposition. It has always conducted its operations to meet its business objectives and has endeavoured to maximise their impact to benefit the people of the kingdom.

LIVING ENERGY EFFICIENCY

In 2015, Aramco continued making progress toward becoming self-sufficient in meeting its own needs for electricity while also increasing energy efficiency. On a national level, Aramco supported the efforts of the Saudi Energy Efficiency Programme (SEEP), a subcommittee of the Saudi Energy Efficiency Centre (SEEC), to improve domestic energy efficiency.

Its energy efficiency efforts are guided by its Energy Management Programme, which is rooted in four core principles: Reduce energy consumption at its facilities by 2 per cent per year, design new facilities to be energy efficient, increase overall energy efficiency, and influence and promote energy efficiency at the national level. One measure of success is energy intensity – the energy required to produce one barrel of oil equivalent expressed in terms of thousands of Btu. In 2015, its energy intensity was 108,000 Btu per barrel of oil equivalent at year-end – an improvement in efficiency of nearly 8 per cent compared to 2014 and 23 per cent compared to 2011.

LEADING BY EXAMPLE

|

|

KAAC ... playing a stellar role |

Saudi Aramco is targeting a 35 per cent reduction in energy consumption in its buildings, transportation, and communities by 2020, and by doing so it is creating a model for other companies to emulate. Lighting and air conditioning are two of the largest consumers of power in office buildings and communities. Realising energy savings in these two areas alone can significantly lower consumption levels.

In 2015, Aramco completed a programme to replace more than 550,000 incandescent lights with efficient LED bulbs. Air conditioning and heating systems account for 70 per cent of the total energy consumption in homes and buildings. By installing smart energy meters and more efficient air conditioners, and upgrading external insulation in its communities, Aramco is reducing power consumption and setting an example for the construction industry to follow.

In 2015, Aramco continued to make progress toward its targets of installing smart energy meters in 1,000 homes and 350 commercial buildings by 2016. The energy efficiencies gained in its homes and commercial buildings will save more than 1 million barrels of oil equivalent per year, equal to avoiding more than 330,000 metric tonnes of CO2 emissions each year, roughly the amount emitted by more than 60,000 cars in one year.

In transportation, Aramco is replacing more than 7,600 V-8 cars and trucks in its vehicle fleet with six-cylinder models. This past year alone (2015), Aramco replaced nearly 1,500 passenger cars and 1,500 trucks.

Improving the overall fuel economy in its vehicle fleet will generate an annual savings of more than 40,000 barrels of oil equivalent. Aramco also switched more than 1,100 hydrocarbon tankers operated by a contractor from steel to lighter weight aluminium, increasing safety and generating additional fuel savings.

To help increase fuel efficiency nationwide, Aramco worked closely with SEEP on a government awareness campaign to promote simple fuel economy tips for drivers in the kingdom. Cogeneration Achieving self-sufficiency in electrical power for its operating plants through cogeneration is a key element of its energy management efforts.

Cogeneration systems capture the heat from a plant’s exhaust stream and convert it into useful thermal energy, lowering fuel requirements and reducing emissions. In 2015, Aramco added a total of 2,163 megawatts of power generating capacity.

Aramco completed the expansion of cogeneration units at its Ju’aymah, Shedgum, and ‘Uthmaniyah gas plants and are building new cogeneration power facilities at its Abqaiq, Hawiyah, and Ras Tanura facilities. The power plants will be owned and operated by a joint venture between domestic companies and Saudi Aramco.

Its grass roots Fadhili Gas Plant will include a cogeneration plant with the capacity to produce roughly 1.3 gigawatts of power and 3.2 million pounds per hour of steam. Aramco continued work on the front-end engineering in 2015 as part of its Joint Development Agreement with the Saudi Electricity Company and a third party.

RENEWABLE ENERGY

Research into the practical and scalable use of renewable energy, particularly solar and wind, combined with engaging key stakeholders, lie at the heart of its efforts to catalyse the kingdom’s renewable energy policy and help optimise the energy mix.

Aramco continued to build momentum in its analysis and application of solar power during the year. Working with the Saudi Electricity Company, Aramco installed 10 monitoring stations at various project sites to calculate potential energy yields and determine the best locations for siting future solar power facilities.

New solar installations in 2015 included its first rooftop photovoltaic setup on its Power Systems office building in Dhahran. The system includes 144 photovoltaic modules, and over its lifespan, will generate approximately 1.2 million kilowatt hours of clean energy, mostly during peak demand times.

At its Tabuk Bulk Plant, Aramco commissioned a 1 megawatt pilot project using concentrated photovoltaic technology – the first such utility scale plant in the Middle East. A solar thermal water heating system, designed to raise energy efficiency by 60 per cent, was installed in the main building of JHAH in Dhahran.

Its research into solar energy is also calculated to result in knowledge and technology transfer to the kingdom and to create new opportunities for business growth and job creation. Aramco is beginning to see early signs of success as evidenced by the completion of a feasibility study with a local company and Solar Frontier, a subsidiary of Showa Shell, its affiliate in Japan, for creating a fully integrated solar manufacturing entity in Saudi Arabia.

Following completion of a wind resources assessment in 2014 at seven locations across the kingdom, Aramco upgraded wind masts and installed nine additional monitoring stations. Data gathered from the 16 masts will help confirm likely production yields from potential wind power sites.

MEETING DEMAND

|

|

KFUPM ... nurturing talent |

Wise stewardship of domestic energy consumption is imperative to ensure the future prosperity of the kingdom. Electricity demand has grown more than 7 per cent per year during the last decade. One approach to managing energy demand growth is to raise the efficiency of the country’s utility sector, a focus of its Energy to the kingdom (E2K) initiative. In 2013, utility sector efficiency stood at 32 per cent. At year-end 2015, efficiency was boosted to 35 per cent, a full percentage point above the target of 34 per cent.

The long-term goal is to raise efficiency to 45 per cent and minimise the use of diesel for power generation. Its Peak Seasonal Production Strategic Plan optimises spare plant capacity and gas production priorities in coordination with reservoir management best practices to supply additional gas volumes to meet power requirements during peak demand periods to reduce the use of liquids.

In 2015, the plan enabled the company to save 2.8 million barrels of oil equivalent. Since starting the programme in 2010, Aramco has saved more than 28 million barrels of oil equivalent, reducing emissions and freeing up greater volumes of crude oil for refining into higher value products and for export.

A more efficient energy sector requires upgraded skills and knowledge. To help prepare the workforce, Aramco signed a Memorandum of Understanding in December with the Technical and Vocational Training Corporation (TVTC), the Saline Water Conversion Corporation, King Fahd University of Petroleum and Minerals (KFUPM), the Saudi Electricity Company, General Electric (GE), and Siemens, to establish National Power Academies in the Dammam and Al Hasa areas.

The Academies will develop world-class training institutes, providing new and emerging programmes, including renewables, energy efficiency, smart grids, realistic labs and workshops, and applied research and development centres.

Nurturing the development of a globally competitive domestic energy sector is a keystone of its approach to leverage its core activities and capabilities to spur economic growth and create new jobs. In December, Aramco launched its In-kingdom Total Value Add programme, designed to position local content at the heart of its procurement process.

The programme’s goal is to double the production of locally manufactured energy-related goods and services contracted by Saudi Aramco to 70 per cent and increase the export of Saudi-made energy goods and services to 30 per cent by 2021. Development of the Saudi workforce is also one of the primary goals of the programme, and Aramco envisions the domestic energy goods and services sector delivering thousands of direct and indirect jobs for Saudis over the long term.

The programme will benefit from collaborative connections with R&D centres and entrepreneurship and incubation hubs such as Dhahran Techno Valley. Its efforts to improve science, technology, engineering, and math (Stem) education in the kingdom will help strengthen the enabling environment for the programme, as will its partnership with the Ministry of Labor to establish 25 national training centres – eight of which are already active,with 12 in development and five in the planning stage.

The scale of its business and associated capital expenditure programmes creates significant opportunities for suppliers to invest in Saudi Arabia and partner with the company on a long-term sustainable basis. Aramco expects to spend more than $300 billion over the next decade, of which 70 per cent will eventually be local content, driving economic diversification, increased global competitiveness, and domestic job creation.

In 2015, Aramco awarded 37 per cent of its material procurement spending, worth $2.1 billion, to local manufacturers while the value of its contracts awarded to local companies reached $26 billion, representing 80 per cent of its overall contract procurement.

Aramco continued the development of the Ras Al Khair Maritime Yard near Jubail on the Arabian Gulf coast. This world-class ship repair and fabrication yard will include state-of-the-art facilities for building, repairing, and maintaining ships, offshore drilling rigs, and offshore platforms.

During 2015, Aramco signed a Memorandum of Understanding with a South Korean firm to develop the yard and also drive advancement of maritime diesel engine manufacturing in the kingdom.

Aramco estimates this project has the potential to generate more than 80,000 direct and indirect jobs, and will position the kingdom to be a technology hub for regional maritime engineering and construction expertise.

The future for the offshore fabrication industry in Saudi Arabia is promising, given the prospects for growth in the region and its own forecasted requirements. For example, a local fabrication yard in the Dammam Port has supplied the company with more than 90,000 metric tonnes of offshore equipment in recent years, including platforms deployed in its Hasbah and Arabiyah fields.

By sourcing materials and services locally, Aramco helps create jobs for Saudis and drive the development of capabilities needed for producing export quality goods – an essential basis for sustaining wealth creation in the kingdom.

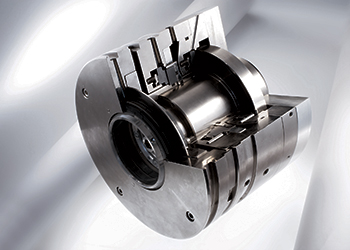

Aramco took steps toward launching a new onshore rig manufacturing initiative that will leverage its significant capital outlays for drilling services. Aramco completed pre-feasibility studies with four companies and analysis and discussions are ongoing.

Since this industry is equipment and materials intensive, it offers an opportunity for the company to localise production and secure supply chain elements that serve both its needs and those of regional markets.

Aramco is exploring the possibility of creating a company that can competitively manufacture and supply the company – and other companies in the region – with drilling proppants, used in the hydraulic fracturing of oil and gas wells.

Phase I of the pre-feasibility study for ceramic-based proppant manufacturing was completed in 2015. Aramco expects to spend more than $300 billion over the next decade – targeting 70 per cent local content. Its investments to promote the development of world-class energy goods and services industries in the kingdom will encourage further investment in the country, spur economic diversification, and drive job creation.

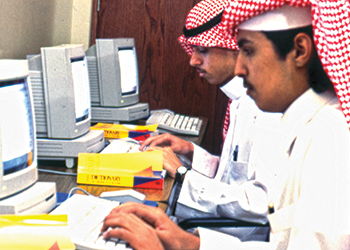

COMPETITIVE WORKFORCE

|

|

Aramco’s human talent manifests itself |

The future success of its business depends not only on the prudent management of the kingdom’s hydrocarbon resources – it also hinges on providing opportunities for people to develop the skills they need to imagine, design, and produce high-value products and services.

Whether through skills training, financial support, or partnerships based on complementary expertise, Aramco is building the foundations for sustainable economic growth in the kingdom.

The nonprofit National Industrial Training Institute (NITI), a joint venture with TVTC, continued to grow in 2015 with the inauguration of the Al Hasa branch in June. Designed to train and develop Saudis from high schools and technical colleges for higher skilled fields, the NITI campuses in Al Hasa and Abqaiq feature state-of-the-art classrooms, labs, and workshops for a combined total of nearly 3,500 trainees.

By the end of the year, 70 NITI graduates joined its operations and those of its domestic ventures, while another 1,300 trainees signed employment contracts. Formed in collaboration with its local and international engineering, procurement, and construction contractors on the Jazan Refinery and Terminal project, the Jazan Contractors Consortium for Training and Employment (Maharat) develops young Saudis from the Jazan region for specialised construction trades.

In 2015, a total of 715 Saudis graduated and received jobs and more than 1,100 were enrolled at year-end. Over the next four years of the refinery project’s construction phase, Maharat is expected to train and place roughly 5,000 Saudis for construction-related jobs.

One of the service industries primed for growth in the domestic energy sector is inspection and quality assurance. To help meet its own anticipated manpower requirements and those of other companies, Aramco supported the establishment of the Inspection Technology and Quality Assurance National Institute to prepare young Saudis for these new careers.

The institute commenced operations late in 2015 at TVTC’s newly constructed facility in Ju’aymah with a capacity for up to 2,000 trainees per year. In November, Aramco signed a Memorandum of Understanding with Princess Nora Bint Abdulrahman University and a local contractor to support the creation of a Women’s Business Park.