Norinao Sato

Norinao Sato

The company’s innovative AI-driven technologies enhance plant control, boost productivity, and support sustainability, positioning it as a leader in the transition toward industrial autonomy across various sectors, Norinao Sato tells OGN

Yokogawa Electric Corporation is making waves in the industrial sector with its cutting-edge AI-based solutions designed to enhance plant control and operational efficiency.

The company’s innovations harness deep learning algorithms to continuously adapt and optimise processes in real time. This shift not only boosts safety and reliability but also leads to significant cost reductions, marking a transformative step towards autonomous industrial operations.

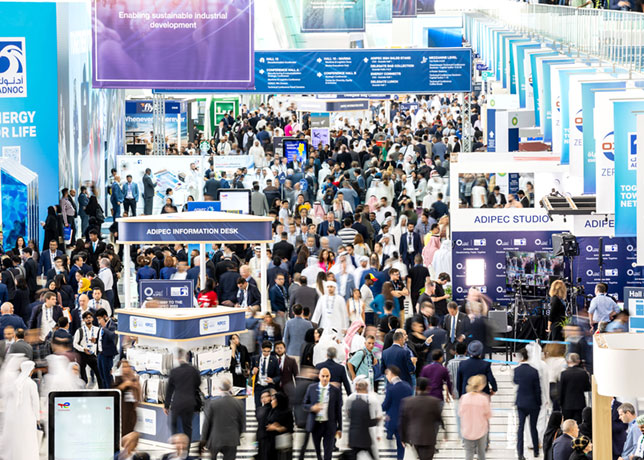

In an exclusive interview with OGN energy magazine, Norinao Sato, CEO of Yokogawa Middle East & Africa, says the company is expanding its AI capabilities, particularly within the oil, gas, and chemicals industries, and it is poised to significantly enhance productivity while ensuring compliance with stringent safety standards.

Below are excerpts from the interview:

• Yokogawa has rolled out several AI-based solutions to improve plant control. Could you elaborate on how these innovations differ from traditional automation systems and their impact on safety, reliability, and cost reduction?

Unlike traditional automation systems that are reactive and rely on predefined control parameters, Yokogawa’s AI-based solutions use deep learning algorithms to continuously learn and more proactively adjust processes to prevent deviations, even in highly complex systems.

These AI systems are more adaptive and able to optimise operations beyond human capabilities, and significantly enhance process safety and reliability.

The shift towards AI-driven autonomous control reduces human intervention, thereby minimising errors and downtime, and cutting operational costs.

|

Yokogawa's vision for industrial autonomy sees plants move from basic automation to full autonomy |

• With Yokogawa’s expanding AI capabilities, particularly in sectors like oil, gas, and chemicals, how are these solutions enhancing productivity and compliance with stringent safety standards?

Yokogawa’s AI solutions are designed to reduce manual work, minimise downtime, and improve quality control on complex operations.

By improving monitoring, risk detection, compliance, and overall safety management, it enhances the supply chain operation and enhances decision-making faster. This helps companies to focus more on amplifying productivity gains.

For example, Yokogawa's AI-driven systems can predict equipment failure, ensuring compliance with safety standards while reducing the risk of unplanned outages.

• Yokogawa's Autonomous Control AI (FKDPP) is a major innovation in reinforcement learning for industrial processes. How has this AI technology transformed real-time operations in complex plants, and what measurable efficiency gains have clients reported?

Yokogawa's FKDPP, is transforming real-time operations by implementing AI reinforcement learning to optimise complex plant processes autonomously.

Clients have reported a more stable process control that leads to yield improvement, reduced energy consumption, and autonomous handling that leads to significant production cost savings.

One of the many potential areas is the Offshore platform, generally remote and under harsh environments, whereby this application can operate autonomously.

The strength of AI is that the system can be designed to adapt to dynamic changes and learn from process conditions to make real-time decisions, improving the agility and resilience of plant operations.

• How has this success impacted your vision for Industrial Automation to Industrial Autonomy (IA2IA), and what role do you foresee AI playing in transforming operations across various industries in the near future?

This success strengthens Yokogawa's vision for Industrial Autonomy (IA2IA), wherein plants move from basic automation to full autonomy.

AI autonomous control plays a critical role in self-optimising, self-healing, and self-regulating systems across industries like oil and gas, chemicals, and energy, further enhancing the capabilities for fully autonomous operations in the future.

• Yokogawa’s e-RT3 Plus Industrial AI Platform integrates AI for edge computing and real-time operations. How is this platform shaping the future of predictive maintenance and operational efficiency for industrial clients, especially in energy-intensive sectors?

Yokogawa’s e-RT3 Plus platform is designed to handle edge computing. Integrating AI allows real-time data processing and predictive analysis that significantly reduces latency and improves operational efficiency almost instantaneously.

In energy-intensive sectors like petrochemicals and power, this platform enables early fault detection and reduces unplanned downtime.

Clients benefit from predictive insights, which optimise asset performance with condition-based Monitoring, leading to reduced operational costs and enhanced productivity.

• Yokogawa has been actively involved in projects across the MEA region. Could you share details on significant recent projects and how your AI and digitalisation strategies are tailored to meet the unique demands of these markets?

In the MEA region, Yokogawa has successfully implemented several AI-driven projects that cater to the unique challenges of energy-intensive industries in the area.

Projects such as the optimisation of refinery and upstream operations using AI-powered analytics have demonstrated measurable improvements in energy efficiency and operational reliability.

Digitalisation strategies focus on integrating AI to meet local market demands, such as enhancing process safety in the oil and gas sector or boosting productivity in large-scale manufacturing facilities.

Looking ahead, Yokogawa Gen AI will focus on leveraging large language models (LLMs) and operational technology (OT) operational assistance.

• In what ways are Yokogawa’s AI-driven solutions helping industries achieve their sustainability targets, particularly in the areas of energy consumption reduction and carbon neutrality?

Yokogawa’s AI-driven solutions are helping industries reduce energy consumption and achieve carbon neutrality by optimising plant operations.

AI tools like FKDPP, which I mentioned earlier, help minimise energy wastage by ensuring process efficiency and identifying opportunities to reduce emissions.

Furthermore, Yokogawa supports the deployment of carbon capture technologies and enhances energy efficiency in high-demand sectors, directly contributing to client sustainability goals.

• As industries transition toward green energy, how is Yokogawa assisting clients in integrating renewable energy sources (RE) into their operations, and what role does AI play in optimising the use of these resources?

As industries transition towards green energy, Yokogawa assists clients by integrating renewable energy sources (RE) like solar, wind, and hydrogen into their operations.

AI helps optimise the energy mix by forecasting energy demand and supply, ensuring optimal use of renewables.

Yokogawa’s sustainable solutions (such as BaxEnergy, GridBeyond) are integrated with AI to balance loads between traditional energy sources and renewable resources, enhancing efficiency and stability in the energy grid and transaction.

• Hydrogen is rapidly emerging as a key component of future energy systems. How is Yokogawa positioning itself in the hydrogen sector, and what specific technologies are you developing to support the safe and efficient production and usage of hydrogen?

Hydrogen is a strategic focus for Yokogawa as part of its commitment to a sustainable future. The company is developing technologies to support the safe production, storage, and transportation of hydrogen.

Yokogawa’s AI-driven solutions for process control in hydrogen production ensure efficiency and safety, while their monitoring tools provide real-time insights into hydrogen usage across various applications, from industrial plants to transportation systems.

• Yokogawa's vision for Industrial Autonomy (IA2IA) highlights the transition from automation to full autonomy. What are the next major technological advancements Yokogawa foresees in achieving true industrial autonomy, and how will AI facilitate this shift?

Yokogawa envisions AI and machine learning as the core enablers for the next phase of industrial autonomy.

Technologies such as autonomous control systems, AI-powered analytics for predictive maintenance, and digital twins will be the foundation for achieving full autonomy.

The future lies in systems that not only react to real-time conditions but also anticipate and adapt autonomously, reducing human involvement.

By Abdulaziz Khattak