Abdrabbuh ... creating maximum value to customers

Abdrabbuh ... creating maximum value to customers

The technology leader, which aspires to at least double the size of its Saudi business with more local content, is focusing heavily not only on legacy technology improvements but also on future technologies

Yokogawa, a top-notch Japanese pioneer in distributed control systems, has positioned itself at the leading edge of the technology wave sweeping the region’s industrial sector in the form of "Industrie 4.0", Industrial Internet of Things, Robotics, Analytics and Big Data.

The technology leader, which aspires to at least double the size of its Saudi business with more local content through the business opportunities presented by Saudi Arabia’s Vision 2030, is focusing heavily not only on legacy technology improvements but also on future technologies, Ahmad Ali Al-Abdrabbuh, senior executive vice president and board director, Yokogawa Saudi Arabia, and Dr Darius Ngo, general manager of Yokogawa’s Process Solutions Sales Division, tell OGN in an exclusive interview.

"We see a big change in the market itself, especially in Saudi Arabia and the GCC. Many companies are looking for ways to transform digitally, but are still questioning what solutions are viable for them to make this transformation. It challenges us to create a new kind of vision for our usual industrial automation market to extend our services beyond the conventional to adopting a more proactive approach in anticipating needs. Digitalisation transforms our technologies beyond regular automation to be more predictive on where optimisation can be achieved. In terms of technologies that is a big change. It has also changed the mindset of people in the R&D," says Dr Darius.

The company, which has embraced digital transformation in a big way, has recognised the direction of the changes and the challenges posed by them, and is co-innovating with its major customers and business partners so as to tackle and capitalise on them, turning them into opportunities rather than seeing them as obstacles, says Abdrabbuh.

Commenting on how the momentous changes will affect the markets, especially Saudi Arabia, he says the kingdom has devised an ambitious Vision 2030 and a few of its pillars are the prosperity of the people, the generation of technology and intellectual property, and diversifying its revenue streams beyond oil and petrochemicals.

"Hence all stakeholders in Saudi Arabia have been driving and strategising towards future technologies to attract foreign investments and intellectual capabilities. The companies with enabling technologies to drive that vision would be partners and co-innovators with the kingdom."

"Yokogawa is well positioned to help drive this vision. We have been working with stakeholders in creating technologies within Saudi Arabia and from our global R&D to anticipate the need and to have the technologies available before the challenges pose themselves and disrupt the industry or society," he says.

On how Yokogawa is gearing up to be the enabler of the next Industrial Revolution, Dr Darius says: "Yokogawa is not satisfied by just complying with the Industrial Revolution 4.0. In fact, our vision is not just Industrie 4.0 but Japan’s Society 5.0 as well as other such global visions on technology. We want to bring Artificial Intelligence (AI) into our technologies as part of Society 5.0. We are introducing AI in a big way; another entrant is machine learning as well as several other enabling technologies."

"Recognising the challenges, Yokogawa has acquired and invested into different technologies, companies and capabilities to position itself to innovate for that future challenge and to cater for the enabling technologies of the Industrial Revolution 4.0 or Society 5.0 or whatever different countries would call the ongoing revolution," says Abdrabbuh.

To bolster its ability to better serve its customers’ requirements and boost its capabilities in the digital sphere, Yokogawa has also turned to the mergers and acquisitions route. In 2016 alone, the organisation made two landmark acquisitions with KBC Advanced Technologies and Soteica Visual Mesa. These strategic acquisitions are helping Yokogawa drive differentiated customer value by discovering areas for improvement, automating the manufacturing processes and sustaining these benefits.

|

Yokogawa is gearing up to be the enabler of the next Industrial Revolution |

Abdrabbuh foresees that solution provider engagement will change from project-based milestone engagements to lifecycle/continuous engagement models. "The oncoming era will see solution providers evolve in two primary ways -- becoming trusted partners and open digital platform providers who have the ability and domain knowledge to solve multifaceted customer challenges; and delivering outcomes-based services on business-level KPIs," he says.

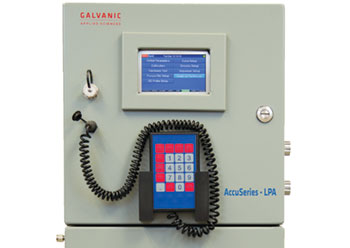

In line with this trend, Yokogawa offers KBC Co-Pilot and Operational Excellence Consulting Services (OpX) as two lead solution offerings in this space on its infrastructures.

"KBC Co-Pilot is the implementation of online models or so called ‘digital twins’ of the asset to continuously monitor and forecast unit equipment performance and energy consumption with centrally-based or globally dispersed experts, providing Co-Pilot opinions to the operators. This can be expanded further to a full Operational Excellence study of the facility and capture and improvement of best operating practices within the digital twins," he explains.

"Yokogawa is developing new synergetic products and solutions that capitalise on future Industrial Revolution 4.0 enabling technologies such as artificial intelligence, machine learning, fog computing - you name it, it’s all coming together," Abdrabbuh says.

On how Yokogawa will help customers achieve a transformation in their productivity through the company’s AI, IIoT, and cloud-based products and other solutions, he says the company increasingly observes that the sharing of challenges, based on trust and collaboration, will grow along with an intensified focus on delivering outcomes. The company has identified a core set of critical issues and a number of solutions for its customers. They are:

Critical Issue #1: Digitalisation – Technological advancements and the widening divide between workforce and operational complexity are driving the adoption of digitalisation technologies. Customers are embracing solution approaches such as digital twins to virtually mimic the performance of the asset, while delivering performance optimisation in real time. Also, Yokogawa expects AI technologies to infuse new levels of agility and predictability in performance. While the future looks bright and interesting, not all customers are at the same digital maturity level. The disparity is driven by factors including lack of learning culture, change management and the like. Large operating companies have a digital office that pulls in stakeholders from multiple domains to nurture cross-pollination of ideas and collaborative decision-making. One has seen large operating companies across industries embrace/embark on the digital transformation journey.

Critical Issue #2: CAPEX → TOTEX – Volatility and lower oil prices hit CAPEX cycles very hard and signalled a shift in customer strategy from investing in new assets to optimising performance of the existing installed base. The OPEX phase can continue for more than 40 years. Customers are now moving towards Total Expenditures (TOTEX). TOTEX is defined as CAPEX + lifecycle OPEX. "As managed service models continue to make inroads, we have seen cases amidst customers where multi-year service contracts are bundled along with the asset at the CAPEX stage itself." Customers look to outsource non-core activities so they can focus on core activities. This creates the demand for outsourced/managed services and Yokogawa expects to see more adoption in the near future. In line with this trend, we found more than nine unique business models that are being used across industries today. Two unique business models that Yokogawa sees are as follows:

Performance-based contracts: These are service-level agreements paid on delivering a level of performance based on KPIs. For example, payment may be based on the level of system availability rather than a lump-sum fee at the beginning of the project.

|

Dr Darius ... providing cutting-edge solutions |

Zero upfront payment business model: In this case, certain elements of the project (such as sensors) are provided with no upfront payment in return for a multi-year monitoring and performance enhancement engagement.

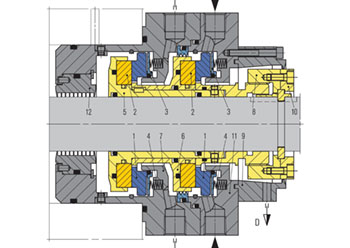

Critical Issue #3: Layered → Networked architecture – The traditional ISA-95 Level 1 to Level 4 architecture is poised to be replaced by pillared or networked architecture, wherein sensors can communicate directly with enterprise systems. As the layers converge, the company sees level 1, 2 and 3 converging into one level. Also, controls will become more decentralised with more computing horsepower being pushed to the edge. Accordingly, cybersecurity is becoming increasingly important for OT/IT convergence as one of the highest level critical issues in customers’ business.

Giving an example on the company’s use of sensors, Dr Darius says Yokogawa has recently launched the Sushi Sensor, which focuses on plant assets, simultaneously measuring vibration and surface temperature of equipment with the objective of optimising the maintenance function as well as energy management.

Critical Issue #4: Sustainability – The United Nations has developed a set of 17 key Sustainable Development Goals (SDGs) that are expected to transform the world by 2030. To achieve the SDGs, one must change from current linear economic model of "Take and Waste" to a circular economic model of "Reduce, Reuse, and Recycle" based on long-lasting design. While the initiatives are diverse, many are connected to industrial end markets -- industry innovation, sustainable cities, partnerships, and responsible consumption and production. As customers look to align themselves to these goals as part of corporate responsibility, they look for trusted partners aligned with the same SDG goals, such as Yokogawa, who can help in and support achieving them.

|

Yokogawa’s Synaptic Business Automation model |

Critical Issue #5: Intelligent operations – In the next 10 to 15 years, process industries will transform into fully integrated value chains delivering end products at consistent quality levels every operational day. Systems and assets will become self-healing, driven by model-based analytics and managed service offerings that will institutionalise a higher level of predictive operations.

Critical Issue #6: Siloed → Enterprise – As process industries continue to innovate and push the envelope of operating parameters, operating companies are looking to adopt an enterprise visualisation strategy. Driven by technology, customers can aggregate different types of data across sites and implement performance optimisation using analytics at an enterprise level. One aspect that many automation companies oversee is the ability to optimise the supply chain.

Dr Darius points out that Yokogawa’s expanding solution portfolio has the capability to address issues within plants that have complex and connected supply chains such as chemical companies, as well as beyond their four walls into the connected supply chain. Cutting-edge solutions such as cloud computing, process data analytics are examples of its all-encompassing value proposition.

Talking about new products, Dr Darius says Yokogawa has unveiled OpreX, an all-new comprehensive brand for the company’s industrial automation (IA) and control business. Under the new OpreX brand, Yokogawa will deliver integrated solutions that support its customers’ transformation and growth through the lens of their business needs.

On the effect of the low oil prices, Abdrabbuh says it has impacted new investment into and businesses in Saudi Arabia. Customers are more cautious about spending and looking more in-depth into new investments and adopting a "wait and see" approach. Yokogawa in general is also affected by the low oil price. However, the company is finding ways to turn these challenges into opportunities.

"We are confident that we will be able to play an important role in the kingdom that will reflect positively on us as well as equally on society. There are a lot of challenges. We work very hard and we are good at turning challenges into opportunities to add value to our customers. We are thus co-innovating the future with our key stakeholders in the region to create maximum value for our customers," Abdrabbuh says.

SAUDI ARAMCO TIES

On the company’s relationship with Saudi Aramco, which has matured over the years, Abdrabbuh says: "We have a technical steering committee jointly with Saudi Aramco. Through this committee, several initiatives have been created and many workshops have been conducted with subject matter experts from Saudi Aramco and globally taking part. In addition, intellectual properties have been generated and piloting, testing and improvement of various technologies and products are ongoing," he says.

Yokogawa Saudi Arabia has a Corporate Procurement Agreement (CPA) with Saudi Aramco, becoming the first automation vendor to sign such an agreement with the Saudi oil conglomerate. The CPA encompasses all the services the company provides to Saudi Aramco, covering equipment supply, project management, engineering, spare parts, and maintenance services. It greatly simplifies the process by which Saudi Aramco purchases process automation equipment from Yokogawa. This agreement is a testimony to Yokogawa’s strong presence in Saudi Arabia.

The company also signed a landmark memorandum of understanding (MoU) last year with Saudi Aramco to cover a number of collaborative dimensions including local manufacturing, and is considering setting up a manufacturing facility at the King Salman Energy Park (SPARK), says Abdrabbuh.

The facility will focus on producing "a certain product range" that meets the requirements of the local and regional markets and will aid in import substitution, he says, without revealing details.

Highlighting the reason for choosing SPARK as the location for the facility, Abdrabbuh says: "We have confirmed the King Salman Energy Park as its location, basically because it encompasses supply chain services and facilities and is a prime location for the Saudi Arabian industry and supply chain infrastructure. SPARK offers a comprehensive ecosystem comprising a world-class infrastructure, logistics and a dry port, shared services, a commercial and residential area and highly specialised training centres.

"We are looking at increasing our business share and our In-Kingdom Total Value Add (IKTVA) contribution through this venture."

Yokogawa has put together a five-year IKTVA plan to be completed by 2022, in line with its goal to improve its IKTVA score as a corporate KPI (key performance indicator). It intends to increase the current localisation percentage of 42 per cent to 60 per cent by recruiting and training more Saudis at various levels in the company. Its actions and strategies are aligned with IKTVA as guided by Saudi Aramco and Vision 2030. Local procurement, more domestic manufacturing, local supply chain and supplier development are some such dimensions.

While industries evolve and face innumerable challenges, Yokogawa has pursued its vision of being a trusted partner to its customers, like its association with Saudi Aramco clearly illustrates.

The company strives to maintain a strong track record of delivering reliable technologies while at the same time continuously evolving to offer digital industrial platforms and concepts like Synaptic Business Automation. These solutions create sustainable value for customers by driving resilient operation, optimised production, and nurture sustained business innovation-. Since its founding in 1915, Yokogawa has been engaged in cutting-edge research and innovation. As a company, Yokogawa’s goal is to contribute to society through broad-ranging activities in the areas of measurement, control, and information.