D’Elia ... presence in the region key for the group

D’Elia ... presence in the region key for the group

In Saudi Arabia, Air Liquide Arabia supplies large volumes of hydrogen to the Yasref refinery, as well as a growing number of large and small scale industries in both Yanbu and Jubail, via its hydrogen pipeline networks

Air Liquide, the world leader in gases and technologies, draws on the expertise of more than 1,100 employees, operates 34 sites in the Middle East, and serves customers in sectors including oil and gas, petrochemicals, metal fabrication, construction, electronics, food and beverage, and healthcare.

Dating back to 2002, Air Liquide’s presence in the region, is key for the group, says Domenico D’Elia, senior vice president, Technology & Sales, Air Liquide Engineering & Construction.

It is from its headquarters in Dubai that Air Liquide oversees its growing operations and investments throughout the Middle East, including the group’s largest single industrial investment -- Air Liquide’s Yanbu Hydrogen Production Site in Saudi Arabia, providing hydrogen to the Yanbu Aramco Sinopec Refining Company (Yasref).

This investment, of more than 350 million euros ($406.01 million), represents both the largest industrial investment and the largest "over the fence" hydrogen contract of the group, says D’Elia.

In Saudi Arabia, Air Liquide Arabia supplies large volumes of hydrogen to the Yasref refinery, as well as a growing number of large and small scale industries in both Yanbu and Jubail (Saudi Arabia’s leading industrial cities), via Air Liquide’s hydrogen pipeline networks. These recently inaugurated networks contribute to the development of the downstream sector in the region, he says.

Oil and gas companies in the region are investing to increase the capacity and productivity of their plants, and are increasingly focused on emerging technologies in fields such as hydrogen production.

Air Liquide Engineering & Construction is one of the world’s leading suppliers of hydrogen plants. "Our hydrogen technologies and excellence in process experience, combined with decades of operational experience, ensures the competitiveness, safety, reliability and sustainability of solutions for customers," he says.

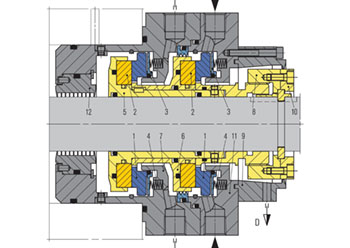

"In the UAE, we own and operate a state-of-the-art manufacturing centre in the Maritime City Free Zone of Ras Al Khaimah, one of three such Air Liquide Engineering & Construction facilities worldwide." The centre provides a large manufacturing capacity to design and produce equipment for very large air separation units as well as hydrocarbon and liquefied natural gas packages, such as columns and cold boxes of up to 600 tonnes. The centre caters to expanding markets worldwide by developing and producing high quality cryogenic equipment, he says.

Air Liquide is also committed to contributing to the improvement of air quality and the fight against global warming. By promoting hydrogen as a key enabler for an effective transition to a low-carbon economy, Air Liquide strives to accompany the region’s environmental efforts.

Recently, Air Liquide and Al Futtaim Motors jointly inaugurated the region’s first hydrogen filling station in Dubai, designed to support the deployment of zero-emission fuel cell electric vehicles (FCEVs) in the UAE, in line with the UAE government’s ambitious renewable energy programme.

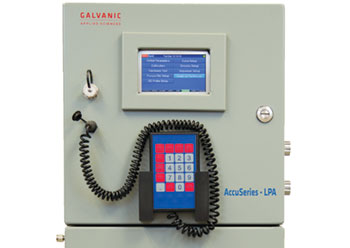

D’Elia says Air Liquide also has the capacity to meet the needs of large, medium, and small customers with a wide range of possible steam export rates. Technologies include steam methane reforming (enabling cost-effective and energy efficient hydrogen production), pressure swing adsorption (to recover and purify hydrogen from various hydrogen-rich streams), as well as tailor-made solutions such as auto-thermal reforming, natural gas partial oxidation (a process for generating syngas and oxogas through GasPOX), and multi-purpose gasification (using Lurgi MPG).

GLOBAL PRESENCE

Air Liquide is present in 80 countries with approximately 65,000 employees, serving more than 3.5 million customers and patients.

Air Liquide Engineering & Construction builds the group’s production units (mainly air gas separation and hydrogen production units) and provides customers with efficient, sustainable, customized technology and process solutions. The company’s core expertise in industrial gases, energy conversion and gas purification, enables customers to optimise natural resources.

The business unit covers the entire project life-cycle: licensed engineering services/proprietary equipment, high-end engineering and design capabilities, project management and execution services. As a technology partner, customers benefit from Air Liquide’s research and development to contribute to the energy transition.

A WORLD LEADER IN CRYOGENICS

Air Liquide is a world leader in cryogenics. Its technology leadership is based on proprietary and exclusively licensed technologies which aim to convert all carbon energy resources into cleaner products. By providing innovative solutions for carbon capture, hydrogen refinery management and air separation, the company is helping customers satisfy stringent product regulations, while enabling plant efficiencies, lower production costs and safe and reliable operations.