The TorcPlug

The TorcPlug

With mounting pressure on the oil and gas industry to deliver safer and efficient well interventions, E Plug’s latest technologies are redefining what’s possible in multi-zone stimulation and rigless perforations

As well designs become increasingly complex in their quest for greater reservoir reach, horizontal sections become longer and begin to stretch the limits of conventional zonal isolation solutions.

Introducing E Plug’s TorcPlug, an innovation that’s transforming how operators approach multi-zone stimulation in horizontal wells

THE CHALLENGE: LIMITATIONS OF CONVENTIONAL METHODS

Modern well designs have become increasingly complex, often involving multiple production zones that require individual stimulation and testing.

Standard isolation methods, such as composite or retrievable plugs, although suitable, have their own drawbacks.

For example, composite plugs produce debris during drillout, requiring cleanout and potentially risking reservoir damage, while retrievable plugs need multiple runs to set and unset.

Both face issues with pressure equalisation before removal, often requiring weight on bit (WOB), which adds constraints to well design.

THE SMART SOLUTION: THE TORCPLUG

|

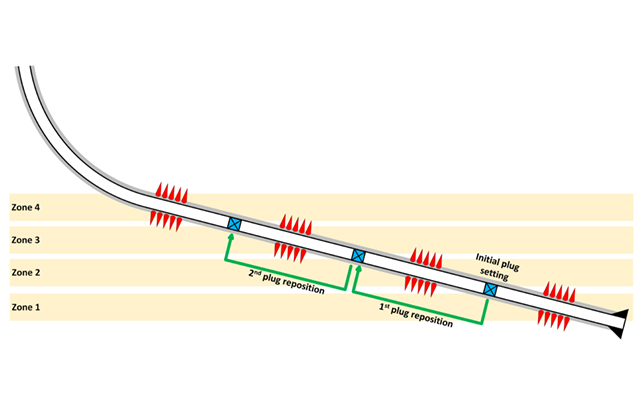

Figure 1 … visual representation of the repositioning of the plug |

The TorcPlug addresses these challenges by allowing operators to set, unset, and reposition the plug without the need to pull out the bottom hole assembly (BHA) from the well. The design operates on the robust "nut-and-bolt" principle to provide the versatility required for addressing these challenges.

This eliminates the requirement for multiple plug deployments and reduces nonproductive time (NPT) (Figure 1).

The Electric Manipulation Tool (EMT) — the running tool — allows for control and monitoring of plug setting and unsetting parameters in real-time, allowing precise adjustments.

Its dual-shaft actuation mechanism enables separate, controlled operation of the valve before unsetting, reducing the risk of pressure shocks and unintended plug movement.

It simplifies deployment and makes the plug suitable even for long horizontal sections, while the full-bore design allows unrestricted flow after retrieval, improving production potential.

|

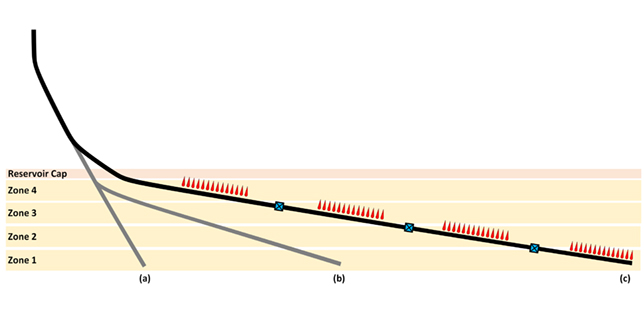

Figure 2 … standard well design (a), Improved design (b) Optimised design (c) |

With design features and recovery tools that allow for contingency retrieval methods, including shear release and milling options, operations are not hindered, and guarantee plug retrieval even in the most demanding conditions.

The technology has undergone rigorous testing and validation, with design iterations that have pushed its limits.

Qualified to V0 and NACE MR0175 standards, it suits sour environments and various acid compositions. Its compatibility with both e-line and e-coil allows operators to optimise equipment for stimulation and plug operations.

UNLOCKING RESERVOIR POTENTIAL WITH INNOVATIVE DESIGN

This innovative technology has already proven its worth in some of the most challenging sour environments in the Middle East.

A prominent operator saved up to three days per well by replacing six runs with three using the TorcPlug. The technology also improved well design by removing traditional plug constraints, enabling optimised trajectories for increased reservoir contact—up to five times more in some cases (Figure 2).

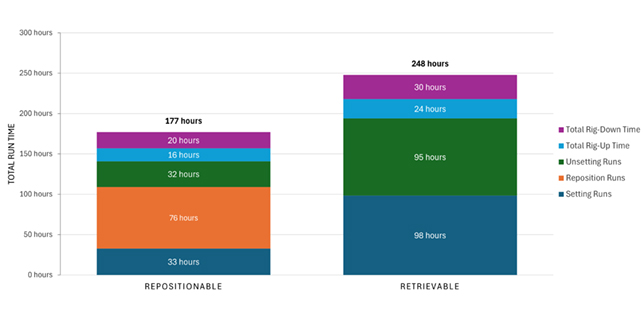

This results in better recovery, higher profits, and more sustainable production, marking a paradigm shift in multi-zone stimulation (Figure 3).

SETTING A NEW STANDARD IN RIGLESS PERFORATION – THE TORCPUNCHER BREAKTHROUGH

|

Figure 3 … average total run time breakdown for repositionable and retrievable plugs for a well with four zones |

In an industry that prioritises safety, efficiency, and innovation, E Plug has developed a new mechanical punching method that eliminates the need for explosives in casing and tubing punching applications.

THE CHALLENGE OF CONVENTIONAL PERFORATION

Perforation is crucial in well intervention, enabling communication between the wellbore and reservoir or annulus.

Usually, explosives-based guns are used, but they pose safety and logistical risks. Alternative methods often lack control, precision, and perform poorly under high pressure, requiring anchoring and stabilisation.

They also need multiple attempts to achieve the desired flow area and face issues with hole cleaning.

These problems are critical in rigless operations where mobility and safety are essential.

Operators have long looked for safer, flexible options that offer the same results with precision and power without the risks associated with explosives.

The TorcPuncher tool from E Plug provides a solution to this challenge.

ENGINEERING EXCELLENCE: THE TECHNOLOGY BEHIND THE TOOL

|

Figure 4 … the TorcPuncher with expanded knives, as seen from below |

The core of the innovation is a modular tool platform comprising the EMT (running tool), TorcDesperado (linear actuator), and TorcPuncher (Figure 4).

It converts rotational torque into bi-directional axial force up to 220,000 lbf, enabling precise, repeatable shearing of tubing and liner.

The TorcPuncher has four knives that extend outward to penetrate the tubing.

This creates large cavities as the blades deform the tubing outward, forming stand-offs.

This design not only ensures efficient fluid flow but also maintains the tubing’s integrity, as no material is lost during punching.

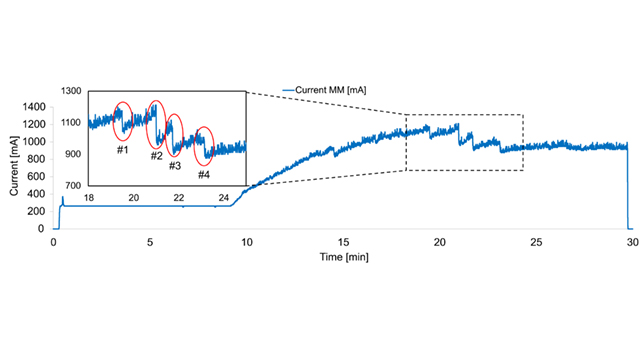

With the EMT providing real-time control of expansion parameters, the cutting and deformation of tubing can be accurately monitored and verified.

The adaptable design allows customisation of perforation geometry and pre-job calibration to control the punched tubing’s outer diameter, ensuring compatibility with casing drift IDs and preventing retrieval issues.

|

The TorcPuncher |

What sets the tool apart is its ability to work with lightweight conveyance systems like e-line and e-coil.

This enables rigless deployment, reducing operational costs and complexity while enhancing safety and speed.

Its built-in contingency release mechanisms ensure retrieval remains possible even in the case of a malfunction.

Designed to handle a wide range of tubing grades, from standard carbon steel to high-strength alloys and corrosion-resistant materials, the TorcPuncher maintains performance across a range of well environments (Figure 5).

The versatility of the solution allows for its application in multiple phases of a well, from completions to workovers and P&A operations. These include:

• Completions and workovers: Enables rapid, low-volume perforations without rig mobilisation.

• Plug and abandonment (P&A): Facilitates perforate, circulate, and cement operations with reduced risk to outer casing integrity.

• Annular integrity testing: Provides access to the annulus for pressure testing and barrier verification.

• Production enhancement: Creates new flow paths in live wells to re-establish or boost production.

In each scenario, the tool’s non-explosive nature and high flow area capabilities deliver operational flexibility and safety.

FIELD PROVEN PERFORMANCE

|

Figure 5 … current signature of one activation, highlighting the four knives punching through the tubing |

A major operator in Norway used the TorcPuncher to relieve trapped annular pressure in a well with compromised tubing.

Due to concerns about high differential pressure, the operator was hesitant to use conventional perforation methods, mainly because of the potential risk of fishing if the BHA experienced an unintended movement in either direction.

The TorcPuncher, with its self-anchoring feature, ensured that the perforation was performed safely under high differential pressure and allowed the operation, which involved twelve punch sequences, to be completed in just five hours.

A prominent Middle East operator faced a challenge with replacing their upper completions, which required that the gas in the annulus be displaced before safely pulling the completions.

The strategy was to punch the production tubing and pump its contents into the formation before pulling the tubing (Figure 6).

This needed the punch to have a high enough TFA to achieve the desired flow rate, while still allowing the completion to be retrieved without restrictions.

Since this was a rigless operation, the available technologies were limited.

The operation was completed in a single activation of the TorcPuncher, reaching the required pump rate for bullheading in less than eight hours from well entry to completion exit.

A NEW STANDARD IN WELL INTERVENTION OPERATIONS

|

Figure 6 … retrieved punched tubing |

As the industry continues to expand the boundaries of complex well design and perforation requirements, technologies such as the TorcPlug and TorcPuncher are establishing new standards for efficiency, safety, and performance.

By decreasing rig time, minimising risks, and supporting rigless deployments, these innovations enable operators to achieve more with fewer resources.

With TorcPlug and TorcPuncher, E Plug empowers operators to achieve safer, faster, and more efficient well interventions, setting a new benchmark for the industry.