The 48-inch pipeline isolated and bends installed

The 48-inch pipeline isolated and bends installed

The operation enabled the completion of a 48-inch tie-in between the Saih Rawl Central Processing Plant and the Saih Nihayda Gas Processing at Gas Network Hub, ensuring uninterrupted gas availability

The Sultanate of Oman boasts an extensive oil and gas pipeline infrastructure. This network forms the backbone of the nation’s energy sector, driving economic growth and prosperity to the country.

Nestled on the Arabian Peninsula with strategic access to the Arabian Sea, Gulf of Oman, and the Strait of Hormuz, the country’s strategic location ensures energy flows smoothly from producers to global markets.

OQ Gas Networks (OQGN) owns and operates over 4,000 km of pipelines ensuring uninterrupted gas supply to consumers across the Sultanate.

Recently, OQGN had a requirement to permanently connect a live 48-inch gas transmission pipeline to newly constructed gas blending stations, the Saih Rawl Central Processing Plant and Saih Nihayda Gas Processing, to enable rich and lean gases to be strategically segregated.

STATS Group was contracted to provide inline isolation services, utilising two Remote Tecno Plugs deployed and pigged 25 km to the isolation location in tandem, to provide a leak-tight and fail-safe midline isolation of the 48-inch pipeline.

Conventional repairs of this type would typically require the entire pipeline to be completely hydrocarbon free and nitrogen purged to enable a safe intervention, interrupting flow of gas to customers and adding extensive operational and procedural requirements. This could result in significant time, environmental and cost implications.

ENGINEERING ASSESSMENT

|

The launcher tie-in |

To fully assess the pipeline isolation project, STATS conducted an engineering study and detailed site-survey to determine the safest method of carrying out the isolation and gather critical pipeline data and dimensions.

Following the study, STATS Remote Tecno Plugs were configured in a three-module train. Design analysis proved this to be the ideal configuration to allow the tool to negotiate multiple bends, travel the 25 km to the isolation location, and provide fail-safe double block and monitored isolation.

To verify functionality for the onshore operations, all equipment was subject to a client-witnessed factory acceptance testing (FAT) programme at the STATS operational facility in Abu Dhabi, UAE.

Tests were performed using a custom-designed test fixture that replicated on-site conditions. Upon the successful completion of all FAT operations, the equipment was mobilised to the site in preparation for the pipeline isolation and tie-in operations.

ON-SITE DEPLOYMENT

|

The 48-inch Remote Tecno Plug installation |

Upon arrival at site and completion of the isolation plug pre-deployment checks, the Remote Tecno Plugs were installed into the launcher and pigged with gas to the isolation location.

During this operation the isolation plugs were constantly monitored and tracked to the exact location and accurately positioned using through-wall communication.

An extremely low frequency (ELF) inductive system hydraulically set and continuously monitored the isolation plug throughout the isolation.

To ensure exact positioning of the isolation plugs in the pipeline, the process involved pigging the first Remote Tecno Plug 150 m downstream of the 24-inch bypass line, and then closing the Block Valve Station (BVS) to redirect the flow through the 24-inch bypass line.

Subsequently, the second Remote Tecno Plug was loaded and pigged to the 24-inch bypass line.

Finally, both isolation plugs were pigged together slowly to the set location.

With the first Remote Tecno Plug at the desired set location, the gas flow was stopped. This halted pigging and allowing the isolation plug to be hydraulically activated, and energising dual seals and taper locks.

To position the second isolation plug to the dedicated set location, the client used STATS-patented mechanical strap clamp to provide a 2-inch offtake to flare a small volume of gas, allowing the isolation plug to slowly reach the desired position.

Venting pressure from between the Tecno Plugs allows the rear plug to be tracked from outside the pipeline to the exact isolation position.

MECHANICAL STRAP CLAMP

|

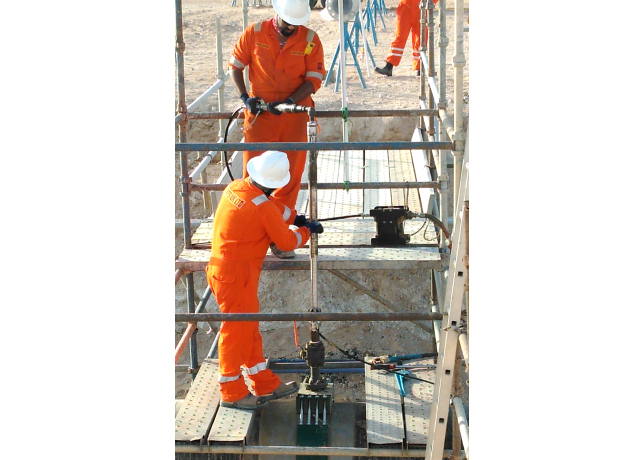

STATS workers on site |

The strap clamp provides a localised seal on a pipe surface with a flanged offtake. This enables hot tapping (drilling) into the live pipeline to provide a vent point for flaring the gas between the isolation plugs.

The strap clamp is simple to install and avoids the need for welding. In addition, due to the simple mechanical installation, the clamp can be removed later in the process, once the pipe section is vented and cut out.

DOUBLE BLOCK ISOLATION SEAL TESTING

Once the isolation tools were accurately positioned, they were hydraulically activated, which compressed the isolation plug, causing the dual elastomer seals to radially expand against the inside of the pipe and taper locks to grip the inside of the pipe.

Large section elastomer seals provided excellent sealing properties even in pipelines with poor pipe surfaces. These were engineered to suit corrosion or ovality issues.

During the isolation setting procedure, the dual seals of the Tecno Plug were independently tested with full pipeline pressure.

As the gas between the isolation plugs was flared to ambient pressure, a pressure differential was generated across the plug module.

As the pressure differential was applied, the trapped pipeline content in between the seals (annulus) was compressed due to the seal compression.

This process tested the secondary seal in-situ at a pressure exceeding the pipeline pressure, in the correct direction, proving the integrity of the secondary seal. The annulus was then vented to ambient and locked-in.

This allowed the primary seal to be tested to the full differential pressure. The isolation was then monitored for an extended period.

Once successfully completed, the isolation certificate was issued by STATS to allow the safe breaking of containment.

Throughout the isolation process, communication was maintained with the Tecno Plugs to constantly monitor and confirm leak-tight isolation.

FAIL-SAFE BY DESIGN

|

The strap clamp flare point |

The fail-safe design of the Remote Tecno Plug used differential pressure acting on the plug to energise the locks and seals. This is referred to as self-energisation.

When the isolation plug was self-energised the isolation is maintained independently of the control system.

It was, however, backed up by the hydraulic control system, which maintained the pipeline isolation when the differential pressure was below the self-energisation threshold.

Once the isolation plug was activated the hydraulic pressure, the circuits were locked in by pilot-operated check valves and fail-safe solenoid valves.

If the control system is compromised, the tool actuation mechanism will unset when differential pressure is equalised.

This feature ensures pipeline integrity is maintained, and that the isolation plug is always recoverable upon job completion.

TIE-IN ACTIVITIES

With the pipeline back flowing with gas diverted through the 24-inch bypass pipeline, and with the midline isolation in place, a 100-m section of pipeline between the Tecno Plugs was cut out and removed.

This provided two tie-in points to connect the bending station launcher and receiver pipelines to the existing pipeline.

Upon completing the tie-in at both locations, the isolation certificate was withdrawn. The new gas segregation plant at GNH was then commissioned by introducing gas and equalising it with the pipeline pressure, allowing the Remote Tecno Plugs to be passively and hydraulically unset and subsequently pigged back to the new launcher and receiver facilities.

Mark Gault, Vice-President for the Middle East at STATS Group, said: "We successfully completed this critical pipeline isolation using proprietary inline isolation tools, enabling a short section of pipeline to be safely isolated at 90 bar. This was achieved without interrupting gas supply to customers and without venting hundreds of kilometres of methane, delivering both operational efficiency and environmental protection."

He said: "This operation enabled OQGN to complete the 48-inch tie-in between the Saih Rawl Central Processing Plant and the Saih Nihayda Gas Processing at Gas Network Hub, permanently connecting the supply pipelines to the newly constructed gas blending station. This ensured uninterrupted gas availability for key stakeholders and delivered a milestone project safely and efficiently."