Faccin factory in Italy

Faccin factory in Italy

The Gulf region will be one of the main drivers of our targeted global growth of 10 per cent per annum, FEDERICO BONFOGO, Senior Sales Manager, Faccin SPA, tells PUMMY KAUL in an exclusive interview

Building on the success achieved in the Middle East over the years, Faccin SPA, a leading global manufacturer of plate and angle rolls, dished heads machinery, and special machines, is spearheading growth across the Gulf by aiming to acquire a leadership position in the region’s machinery sector.

Federico Bonfogo, Senior Sales Manager for Faccin SPA, is confident that by 2022 the Gulf market, which has been a top priority for the company with sales growing by 25 per cent in 2019, will be one of the main drivers of the Italian company’s targeted growth of 10 per cent per annum, globally.

|

The company manufactures a diverse range of plate and angle rolls, dished heads machinery |

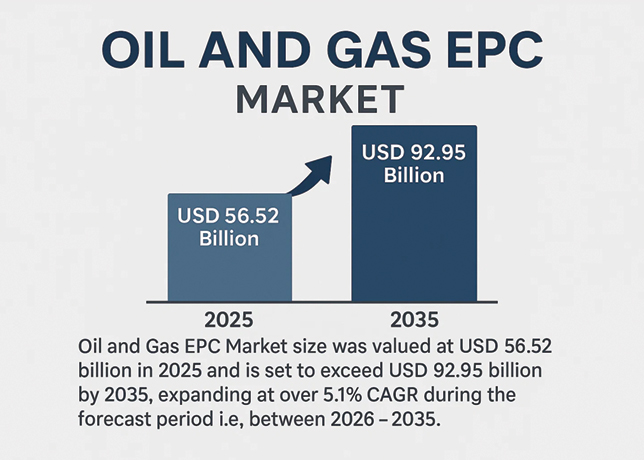

“Our objective for the next three years, based on the excellent results we have obtained in 2019 and the consolidation of our general marketing strategy is to grow at an average of 10 per cent per annum globally. The Gulf market will be one of the main drivers of this growth since our products are suitable for many of the growing industries in the area, not only oil and gas related but also storage tank, shipyards, steel structure, offshore, wind towers and other sectors,” Bonfogo sasy.

With a vast array of products and services, spare parts availability and technical support, Bonfogo is focusing on offering solutions based on more than 200 years of combined experience and product development, all this with the best Italian engineering and craftsmanship.

The Italian group combines three brands – Faccin, Boldrini and Roundo – in plate rolling, profile bending and dished-heads manufacturing, all under one roof and offering the widest range of high-quality options available in the metal forming market.

During 2019, the company commercially consolidated all its three powerful brands. And even if these brands share products in common, each one is recognised as a leader of specific machine types. Faccin for its high-precision plate rollers and design and production of high-profile special machines; Boldrini for its powerful complete dished head lines; and Roundo for its technologically advanced section bending machines.

“We see that the synergies obtained through this process are bringing fantastic results since we can now offer a more varied range of products to our customers for their most challenging projects.

“Our strategy is clearly orientated to offering to the customers solutions based on more than 200 years of combined experience and product development, all this possible thanks to what the best Italian engineering and craftsmanship can bring,” he explains.

CAPACITY EXPANSION

A specialist in the design, manufacturing and sale of plate rolling machines, bending rolls, profile bending machines, dished head machinery and special machines including ship frame benders, hydraulic presses and plate straightening machines, Faccin concentrates its production in Visano, in the Brescia province. The Faccin main facility covers an area of 60,000 sq m, of which 15,000 sq m are taken by the production facilities.

Using the latest technology, the company follows the construction of metal forming machines at every stage, from the receipt of the order to the design by the in-house engineering department; and from the construction of the electro-welded structures to the machining of the structures and the forged rolls up to assembly and shipping.

“Customers are always welcome to visit the impressive Faccin facilities to see the quality of its metal forming machines with their own eyes,” says a proud Bonfogo.

Faccin has been ISO-9001 certified for more than 10 years and implements the Lean philosophy in all phases of the production of its forming machines. “Thanks to Lean manufacturing, Faccin designs future-proof top-level machines with the highest efficiency and the shortest delivery time,” he adds.

Being a manufacturer, procuring most of its raw materials locally has benefitted the group, immensely, says Bonfogo. The company sources all its components and raw materials mainly in Italy, otherwise in Europe. “Since we are manufacturers, not just assemblers, we stock a considerable quantity of components and raw material for the fabrication of our machines and for spares and accessories. This has the advantage that even when certain components or materials are scarce, we can still continue with our normal fabrication and provide our customers with the service and support capital equipment requires,” he says.

The Italian firm has recently expanded its facilities to add more space for stock machines that it produces for quick delivery and the packaging process. In the same facilities (just in front of the main factory), it has now placed its commercial department, in new offices fitted with the latest communication equipment and modern meeting rooms.

“This move has increased at the same time our assembly area in the main factory, allowing us to consolidate the production of all our products, enhancing post-production testing and delivery times,” says Bonfogo.

NEW MARKETS

The company’s 90 per cent production is sold worldwide with Asia, the Middle East, Europe and the US as its main markets.

“This year has been an exceptional year for our group, with sales increases of 25 per cent in the US and the Middle East and an astonishing 52 per cent in Asia thanks to our sales of wind power related products to the Taiwanese market,” he says.

For Faccin, the Gulf has always been a top priority in terms of product development and presence in the market. More so, because of the oil and gas industry that demands powerful and precise machines, particularly in thick plate rolling and the production of dished heads, mostly for the fabrication of pipelines, foundations and pressure vessels.

“When a customer installs our machines in its factory, he gets not only the highest quality machines in the market but also the expertise and support of its technical department, specially in the training of the operators and after sales obtaining the best ROI and long terms benefits,” Bonfogo says.

Talking about some of its notable projects in the Gulf, without divulging the names involved, he says how a large Saudi organisation, approved to be listed in the Saudi Stock Exchange and one of the first companies Saudi Aramco has worked with “in terms of achieving their objectives”, has decided to appoint Faccin to supply them with three 4-rolls plate rolling machines with capacities ranging from 75 mm to 125 mm plate thickness for their storage tank and process equipment business sectors.

These three new rolling machines have been added to a medium sized plate rolling machine they acquired some time ago, a doubtless decision due to their positive experience with the company’s solutions and the after sales support received during these past recent years.

Another demonstration of client loyalty is the installation by an important shipyard based inside the port of Dammam—home to Saudi Aramco and part of one of the largest marine infrastructure companies in Saudi Arabia that controls and manages a number of maritime and construction projects in the Middle East and North Africa (Mena) region—of a 3-rolls plate rolling machine with variable geometry configuration model HAV, an unbeatable combination of rolling power and pre-bending precision.

Furthermore, a Dubai state-owned company, primarily focused on the upstream oil and gas industry with top level customers such as Schlumberger, Halliburton, Baker Hughes, Weatherford, has awarded Faccin with another order for a new plate rolling machine for its new manufacturing facility in Saudi Arabia.

The investment was driven by the need to enhance the company’s IKTVA (in-Kingdom Total Value Added) and thus ordering a 4-rolls plate rolling machine, a solution that combines power, reliability and precision in an exclusive package that makes it the state-of-the-art in modern plate rolls.

“When it was time to expand their factory, due to the continuous growth in customer’s demand, a UAE based company specialised in oil and gas, petrochemical, power and water, marine and mining industries has selected the 4-rolls plate rolling machine as the right answer to its needs,” Bonfogo says.

More importantly, the success obtained in many challenging projects in the Middle East, have led the company to increase the level of trust amongst its clients, showing the company’s long-term commitment and converting Faccin in the number one choice for metal forming machinery, Bonfogo comments.

Hundreds of plate-rolling machines successfully installed in the region from medium thick plates to over 300 mm plate thickness, demonstrate a prompt service support available not only for installation and commissioning but also for training and preventive maintenance makes the company’s plate rolling machines the solution suitable to effectively cover the needs of each manufacturer.