The TM611 non-invasive sensor compared to an invasive method (in the background)

The TM611 non-invasive sensor compared to an invasive method (in the background)

The iTHERM SurfaceLine TM611 is more than just a sensor, it’s a leap forward in industrial measurement technology, writes Egemen Demirkol, Business Development Manager, Endress+Hauser

In the world of industrial process automation, temperature measurement is a critical parameter. It impacts everything from product quality and energy efficiency to safety and regulatory compliance.

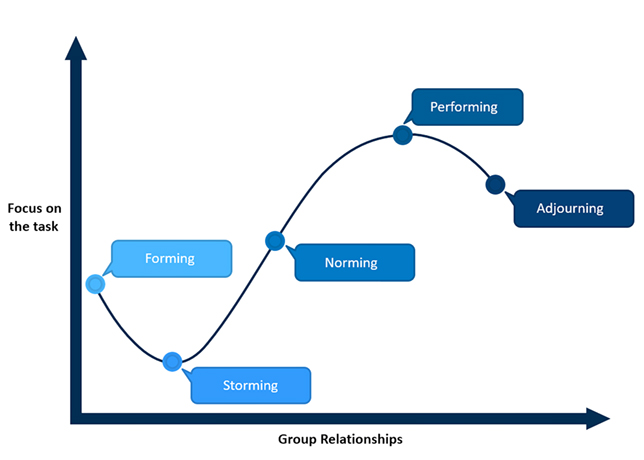

Traditionally, industries have relied on invasive temperature sensors, devices that penetrate the process medium, often requiring complex installation and introducing risks such as leaks, contamination, and process disruption.

"But what if you could achieve the same accuracy and response time as good as invasive sensors, without ever opening the process?" asks Egemen Demirkol, Business Development Manager, Endress+Hauser.

The iTHERM SurfaceLine TM611 from Endress+Hauser, a non-invasive temperature measurement solution, is transforming how industries monitor and control their processes.

Explaining a non-invasive temperature measurement, Demirkol says: "Non-invasive temperature measurement means placing a sensor on the outside surface of a pipe or vessel to determine the temperature of the fluid inside."

This approach eliminates the need for drilling, welding, or installing thermowells, and avoids direct contact with the process medium.

However, surface measurements have historically faced challenges, such as ambient influences (wind, sun, temperature fluctuations); slower response times; and lower accuracy compared to invasive methods.

The iTHERM SurfaceLine TM611 overcomes these challenges through advanced thermal engineering and innovative coupling design.

FUNCTIONING OF TM611

At the heart of the TM611 is a thermal coupling element, a specially designed interface that ensures excellent heat transfer between the pipe surface and the sensor.

|

The TM611 for stainless steel energy applications |

The key features of the TM611 include a large contact area for maximum heat exchange; a geometry matched to pipe diameter to eliminate air gaps; and heat transfer material to compensate for surface imperfections.

Combined with a low thermal mass RTD or thermocouple sensor, this design allows the TM611 to deliver fast and accurate temperature readings. This is comparable to invasive sensors, but without the risks.

The TM611 non-invasive thermometer offers several key benefits, such as:

• Safety first: No process penetration means no risk of leaks or contamination. It also eliminates vibration-induced damage to thermowells thus making it ideal for hazardous environments where safety is paramount.

• Effortless installation: The sensor can be clamped to the pipe, with the need for special tools or complex engineering, saving on downtime. It also eliminates the need for wake frequency calculations, insertion depth studies, or weld seam tests.

• Cost efficiency: The TM611 offers significant cost efficiency by streamlining project engineering, eliminating the need for 3D modelling or material compatibility studies. It reduces procurement and installation costs by not requiring thermowells, flanges, or exotic alloys. Additionally, it minimises maintenance expenses, as its non-invasive design eliminates the risk of breakage and removes the necessity for regular inspections.

• Digital connectivity: The TM611 features robust digital connectivity, supporting all major communication protocols, including HART®, PROFINET, FOUNDATION Fieldbus, and PROFIBUS®. It offers Bluetooth® connectivity for seamless configuration and diagnostics. Additionally, it complies with NAMUR NE107 for advanced diagnostics and meets SIL standards for functional safety.

ENGINEERING FOR EXCELLENCE

The TM611 is engineered for optimal performance, with features such as:

|

The TM611 is engineered for optimal performance |

• Stainless steel screw clamps for easy and safe installation, making it ideal for retrofitting or temporary measurements.

• Flexible positioning at various points on the pipe or across different pipes.

• No drilling, welding, or additional tools are required.

• Thermal coupling element with extra-wide contact surface and geometry adapted to pipe diameter.

• Heat transfer material to compensate for pipe imperfections.

• Standard RTD/TC sensor with low thermal mass for fast response.

To further enhance process optimisation, Endress+Hauser offers a suite of complementary products that together create a complete ecosystem for digital process automation. These include:

• iTEMP TMT162: Field transmitter with a large display and remote mounting options.

• WirelessHART Adapter SWA70: Enables wireless data transmission from hard-to-reach sensors.

• Proline Prosonic Flow W 400: Non-invasive ultrasonic flowmeter for energy monitoring.

REAL-WORLD APPLICATIONS

The versatility of iTHERM SurfaceLine TM611 allows it to be used across a wide range of industries and applications, including:

• Oil and gas (LNG regasification): In LNG terminals, natural gas is stored as a liquid and then regasified. Accurate temperature measurement is critical to avoid leaks and ensure energy efficiency. The TM611 monitors inlet and outlet pipelines without disturbing the flow, providing reliable data for process control and safety.

• Chemical industry (batch reactors and heat exchangers): Batch reactors require precise temperature control to optimise yield and energy use. The TM611 provides fast, reliable readings without contacting toxic or reactive fluids. In heat exchangers, it enables accurate monitoring of temperature differentials, helping to maximise energy recovery and product quality.

• Power and energy (green hydrogen production): In hydrogen production, ultrapure water must be monitored before entering the electrolyser. The TM611 ensures hygienic, non-contact measurement, preserving water purity and system integrity.

• Water and wastewater (sludge treatment): Temperature affects bacterial activity in digesters. The TM611 measures temperature differentials in heat exchangers, helping optimise biogas production and sludge stabilisation.

Some application examples include:

• Hydrogen refuelling stations (safety and precision at high pressure): The challenge here is that Hydrogen refuelling stations operate at extremely high pressures (up to 700 bar) and use very small pipelines (8–15 mm diameter).

Traditional invasive sensors are not feasible due to the risk of leaks and the difficulty of installation.

Moreover, invasive sensors often measure the temperature of the fitting, not the hydrogen itself, leading to errors.

The iTHERM SurfaceLine TM611 offers a solution. It adapts perfectly to small pipe dimensions and provides accurate, fast temperature measurement without opening the process.

Its non-invasive design eliminates potential leak points, a critical safety advantage in hydrogen applications.

The TM611 is available with standard Pt100 or thermocouple sensors and supports all major communication protocols, making integration easy.

The result is a cost-effective, maintenance-free, and accurate alternative to invasive measurement, with the decisive benefit of eliminating leakage risk in hazardous environments.

• Boosting heat exchanger efficiency and safety in chemical industry: In chemical plants, Transfer Line Exchangers (TLEs) rapidly cool ethylene gas from 400-450 deg C to 250-320 deg C.

Accurate temperature measurement at multiple points is essential for process efficiency, product quality, and safety.

High flow rates and vibration make invasive sensors prone to failure, and thermowells can disturb flow and even cause leaks.

In this case, the TM611 offers all the advantages of non-invasive measurement — no fluid disturbance, no risk of leakage, and no need for wake frequency calculations or frequent inspections.

It can be quickly attached to pipes of various sizes using stainless steel clamps.

The TM611 has been tested for vibration and harsh conditions (DNV and IEC 60068-2 standards), ensuring reliable performance.

By measuring temperature accurately and quickly, the TM611 helps optimise heat exchanger performance, improve energy recovery, and enhance operational safety.

• Green hydrogen production (monitoring ultrapure water supply): In green hydrogen production, ultrapure water is split into hydrogen and oxygen in a PEM electrolyser.

Monitoring the temperature of this water is crucial for process efficiency and stack health. The sensor must be hygienic, accurate, and avoid contaminating the ultrapure water.

In this scenario, the TM611 provides hygienic, non-contact temperature measurement, ideal for monitoring ultrapure water supply lines.

Its non-invasive design ensures there is no risk of leakage, process interruption, or product contamination.

The sensor’s advanced thermal coupling element guarantees superior measurement performance, supporting the production of high-purity hydrogen while minimising maintenance and operational risks.

The iTHERM SurfaceLine TM611 is the answer for customers searching for:

• Non-invasive temperature measurement.

• Leak-free industrial temperature sensors.

• Digital temperature transmitters for process automation.

• Easy-to-install, maintenance-free temperature solutions.

The TM611’s unique combination of safety, accuracy, simplicity, and digital connectivity makes it the ideal choice for modern industrial applications.

FUTURE OF TEMPERATURE MEASUREMENT

The iTHERM SurfaceLine TM611 is more than just a sensor, it’s a leap forward in industrial measurement technology.

By combining smart design, advanced thermal science, and digital integration, it solves age-old problems in temperature monitoring.

Whether you’re ensuring safety at a hydrogen station, optimising a chemical heat exchanger, or producing green hydrogen, the TM611 delivers accuracy, safety, and simplicity.