Qamar uz Zaman

Qamar uz Zaman

Enhancing well performance through precision debris recovery, laser-focused magnets are transforming cleanout operations and boosting production efficiency, Qamar uz Zaman tells OGN

In oil and gas drilling, debris retrieval has long posed a persistent operational challenge, particularly in high-risk wells where perforation efficiency directly affects productivity.

Traditional cleanout methods, including the use of conventional magnets, have often delivered inconsistent results, leading to lost productivity and expensive interventions.

Now, a new generation of laser-focused magnets is redefining how operators approach well cleanouts.

The technology, says Qamar uz Zaman, Operations Manager at Innovar Solution Middle East, enables operators to unlock greater well potential through the use of converging shockwaves that enhance debris capture and retrieval efficiency.

FROM CONVENTIONAL CLEANOUTS TO LASER PRECISION

The limitations of traditional magnets became evident during early Petroleum Development Oman (PDO) trials in horizontal wells.

|

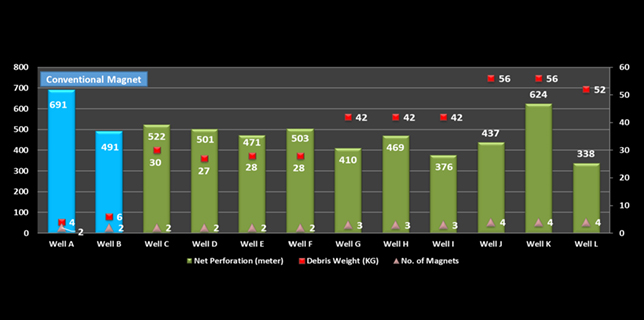

Figure 1 ... Perforation length versus debris retrieved (kg) |

With gun assemblies exceeding 1,000 m and perforation intervals between 150 and 700 m, conventional debris recovery tools failed to capture debris volumes matching the actual gun length.

Initial runs using two conventional magnets yielded inconsistent recovery, with debris weights far below expectations.

Recognising the need for improvement, PDO partnered with RAY International to explore a more effective solution.

The outcome was laser magnet technology, designed to increase precision and retrieval capacity compared to conventional methods.

When trialled with two magnets, the system immediately demonstrated improved results, recovering an average of 28 kg of debris per well, effectively doubling cleanout efficiency (Figure 1).

|

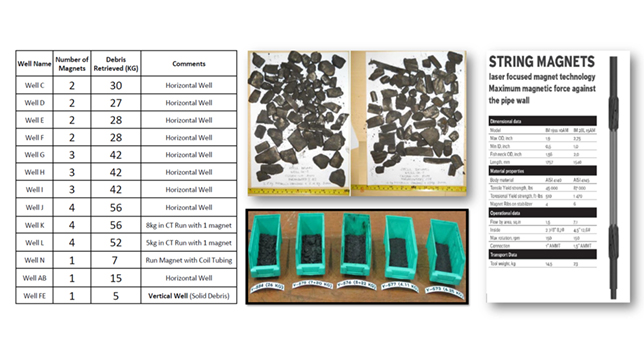

Figure 2 ... Debris collected using laser magnets |

Encouraged by these results, engineers expanded the configuration to three magnets, achieving 42 kg of debris recovery per well, even with shorter perforation lengths.

A four-magnet setup went further still, collecting up to 56 kg in horizontal wells (Figure 2).

The recovered samples included not only perforation gun debris but also pre-existing downhole materials, highlighting the system’s comprehensive cleanout capability.

Each magnet handled roughly 14 kg of debris, creating a scalable, modular solution adaptable to varying well conditions—a major advancement over fixed-capacity conventional systems.

CASE STUDIES DEMONSTRATE CLEAR PRODUCTIVITY GAINS

Beyond impressive retrieval figures, laser magnet deployment also translated into measurable production gains.

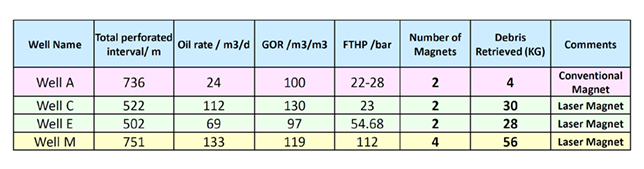

In Well C, where two laser magnets were used over a 522-m perforation, oil production reached 112 cu m per day. This was a dramatic increase compared to Well A, which used conventional magnets across a longer 736-metre interval but produced just 24 cu m per day (Table 1).

Similarly, Well M, equipped with four magnets, yielded 133 cu m per day, reinforcing the direct link between improved debris removal and enhanced flow efficiency.

|

Table 1 ... Productivity data |

The benefits extended to vertical wells as well. In Well FE, a single magnet retrieved 5 kg of debris from a shorter perforation, while another vertical test achieved 7 kg, underscoring the technology’s adaptability across completion types.

In some cases, magnets run prior to tubing-conveyed perforation (TCP) operations using coil tubing exposed pre-existing debris, offering additional diagnostic insight into wellbore conditions before perforation.

PDO also observed broader operational advantages. In the YK field, for example, acid stimulation—previously essential to counter debris blockage—was no longer required once laser magnets achieved cleaner perforation tunnels.

The result was lower intervention costs and reduced environmental impact.

OPERATIONAL OPTIMISATION & FUTURE APPLICATIONS

PDO’s step-by-step validation process (from two magnets to four) marked a deliberate path of technological refinement.

Detailed analysis of debris types guided further optimisation, including the strategic decision to deploy magnets ahead of perforation jobs to prevent tunnel plugging and reduce strain on surface facilities.

As case studies accumulated, standard operating procedures (SOPs) evolved.

Engineers began correlating perforation gun strings with the corresponding number of magnet joints required, enabling a data-driven approach to cleanout planning.

What began as an experimental tool has now become a field-wide operational standard, rapidly establishing laser magnet technology as a new benchmark for debris recovery.

Looking ahead, the focus is expanding to vertical wells, where early results have been encouraging. Ongoing studies aim to refine deployment strategies and further boost performance across varied well geometries.

The success of laser-focused magnets embodies a broader trend within the energy sector, and demonstrates innovation born directly from practical field challenges.

By replacing underperforming conventional systems with precision-based tools, operators are not only improving productivity, but they are also reducing operational risk and cutting intervention costs.

For PDO and its partners, the adoption of laser magnet technology has delivered more than efficiency gains. it has set a new operational precedent for cleaner, safer, and more effective well completions.

As laser magnet systems continue to evolve, their role is likely to extend far beyond individual fields, shaping industry-wide best practice in debris retrieval and well optimisation for years to come.