The PPG PITT-CHAR NX fire protection system meets all the requirements of UL 1709 Edition 5

The PPG PITT-CHAR NX fire protection system meets all the requirements of UL 1709 Edition 5

For regional operators focused on asset longevity, safety, and maintenance reduction, coatings like PPG PITT-CHAR NX offer a proven solution, Richard Holliday tells OGN

The Middle East holds some of the lowest-cost oil and gas resources in the world and it remains a central force in the global energy landscape.

In 2024, the region provided around 30 per cent of global oil production and 17 per cent of global natural gas output, according to an International Energy Agency (IEA) report.

This has led to a surge in investments, with the region set to invest approximately $130 billion in oil and gas supply in 2025, representing about 15 per cent of the global total.

Saudi Arabia alone plans to allocate around $40 billion to upstream oil and gas activities.

From refinery investments in Saudi Arabia and LNG terminals in Qatar to offshore assets in the UAE, oil and gas development is accelerating across the Middle East, driving unprecedented demand for high-performance passive fire protection (PFP) systems

In parallel, the Middle East has emerged as a global fabrication hub, supplying critical infrastructure and components for major projects in markets such as the US.

|

Richard Holliday |

This growth brings complex technical demands. From liquefied natural gas (LNG) terminals to refineries across the Gulf region, these facilities operate under extreme conditions, including intense heat, UV exposure, high humidity, salt-laden air and vibration.

These environments, paired with the ever-present risk of hydrocarbon fires and even the risk of cryogenic exposure, demand PFP that does more than pass laboratory tests.

They must deliver consistent functionality and remain fully available, reliable and survivable in the field for decades without failure, even in the most demanding environments.

ROBUST STANDARDS FOR A TOUGH INDUSTRY

Developments in PFP testing, led by the introduction of Edition 5 of Underwriters Laboratories (UL) 1709 standard, have changed how the oil and gas sector evaluates fire protection coatings.

As part of UL 1709 Edition 5, it became mandatory for products to pass the highest level of UL 2431—the standard for safety for "durability of fire resistive coatings and materials" —to achieve certification.

This requirement introduces significantly more aggressive environmental testing, closing the gap between lab success and in-field survivability.

|

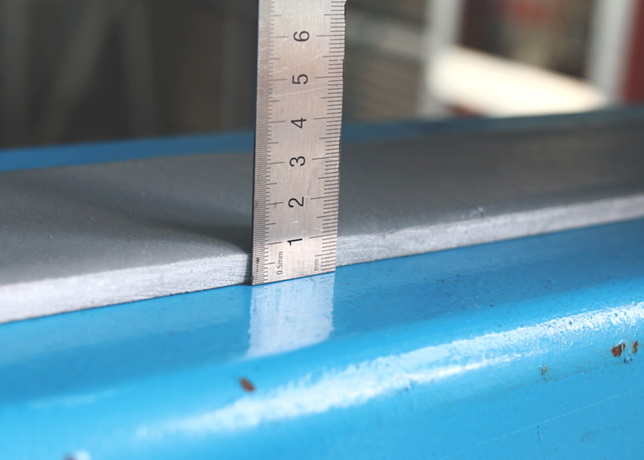

The PPG PITT-CHAR NX requires only 7.88 mm to achieve a two-hour UL 1709 fire rating |

Since the late 1980s, UL 1709 has been the benchmark for testing PFP systems against hydrocarbon pool fires.

Earlier versions included environmental durability requirements, though the testing standards have since become more rigorous.

In many cases, coatings that passed fire tests in the lab failed in the field after exposure to moisture, ultraviolet (UV), temperature swings or handling damage.

Once cracked or delaminated, even the most fire-resistant coating becomes compromised.

UL 1709 Edition 5 addresses this gap by mandating that products must pass the newly adopted UL 2431 durability standard with more stringent fire testing requirements.

This standard more accurately reflects service conditions in the field, making certification both more rigorous and more relevant across varied geographies and applications.

UL 2431 was developed to align more closely with climatic conditions. It includes a range of environmental stress simulations:

• Combined UV and humidity testing (ASTM D4587): Coatings must withstand a 5,000-hour cycle of 8-hour UV exposure at over 70 deg C, followed by 4-hour condensation at 50 deg C, closely replicating challenging site conditions.

• Wet-freeze-dry cycle testing: Products endure 12 cycles of artificial rain (72 hours at 18 mm/hour), followed by deep freezing (-40 deg C for 24 hours), and dry heat (over 60 deg C), which reveal moisture-related damage risks such as cracking.

• Salt spray corrosion test (ASTM B117): A 90-day (2,160-hour) salt spray test evaluates corrosion resistance in harsh marine or industrial conditions.

• High-speed air erosion test (ASTM E859): Simulates long-term wind exposure at 96.6 kmph (60 mph), a particularly demanding test for cementitious systems.

• Impact resistance assessment (UL 2431): A 2-inch steel ball is dropped from 20 ft to simulate mechanical impacts, particularly challenging for cement-based coatings.

• Vibration durability test (10-60 Hz): Identifies failure points under vibration, simulating conditions on offshore platforms or industrial plants.

After completing these tests, UL fire test the coatings and compare the fire resistance to unexposed control samples.

While UL 1709 Edition 4 required the exposed sample to test within a 25 per cent deviation of an unexposed sample’s fire performance, that deviation has been tightened to only 15 per cent since UL 1709 Edition 5.

THE OIL & GAS CHALLENGE

Facilities across the energy value chain (from upstream to downstream) face increasingly complex fire and environmental hazards.

LNG terminals, offshore platforms and onshore refineries and petrochemical facilities all share one need; they need a fire protection system that not only resists heat but also endures harsh environmental conditions without premature failure.

Cryogenic spill protection emerges as another critical requirement, especially in LNG infrastructure.

A coating that becomes brittle under sub-zero conditions could crack and fail before fire even breaks out. The overall durability in PFP thus proves essential.

CASE IN POINT

PPG PITT-CHAR® NX fire protection system meets all the requirements of UL 1709 Edition 5.

|

The PPG PITT-CHAR NX being applied |

Additionally, UL has verified the PFP coating to pass double-exposure testing under UL 2431 without requiring a topcoat.

Designed with a flexible epoxy matrix, the system resists mechanical and environmental stresses without cracking, which is ideal for the harsh conditions of the oil and gas industry.

One example is the Sonker Refinery project at Sokhna Port Basin 3, a critical liquid bulk terminal on Egypt’s Red Sea coast.

Sonker Energy needed to protect 14,000 sq m of steel structures and piping in an environment that combined harsh desert conditions with coastal humidity and salt-laden air.

Compounding the challenge were potential temperature extremes ranging from +50 deg C down to -40 deg C, as well as the ever-present threat of hydrocarbon fires.

PPG PITT-CHAR NX was used for its combination of fire performance, flexibility and proven durability without the need for a topcoat. Applied both on- and off-site, the system was:

• Safer: Engineered to meet the latest severe hazard testing requirements, including high heat flux jet fire and explosion scenarios, helping reduce asset risk in demanding environments.

• Tougher: Designed for long-term durability, the coating withstands stresses and strains during construction, transportation, and service without cracking or delamination.

• Thinner: Requires only 7.88 mm to achieve a two-hour UL 1709 fire rating per UL design XR658.

• Lighter: Up to 15 per cent lighter than alternative epoxy PFP systems and less than one-third the weight of "lightweight" cementitious systems, reducing structural load.

• Faster: Can be applied in a single shift, up to 60 per cent faster than traditional systems, simplifying installation and maintenance, especially in remote locations.

By enabling safe, efficient fabrication and installation, the system allowed Sonker to meet project deadlines while ensuring long-term asset protection.

TOPCOAT OR NO TOPCOAT?

Many PFP systems rely on a topcoat to meet environmental durability standards. The topcoat serves as the first line of defence against UV degradation, water intrusion and mechanical damage.

In controlled environments like indoor facilities, this added layer may perform well over time.

However, oil and gas coatings face salt spray, extreme temperature swings, physical handling and long-term outdoor exposure; the topcoat becomes a potential point of failure.

If it deteriorates or receives inadequate maintenance, it can expose the underlying intumescent layer to damage. Once compromised, the system may no longer provide effective fire resistance.

That’s why systems that maintain durability without a topcoat offer an advantage in high-risk environments.

They reduce maintenance requirements and extend service life, especially in remote or offshore installations where access is limited, and inspection intervals may be long. For operators focused on minimising downtime and total cost of ownership, this distinction matters.

RAISE THE BAR FOR FIRE PROTECTION

Choosing the right PFP system, oil and gas specifiers should ask:

• Was the system tested, assessed and certified in accordance with the latest edition of UL 1709, including full environmental durability?

• Is it listed on UL’s Product IQ database?

• Can it withstand explosions, cryogenic spills, pool fires and jet fires?

• Was it tested as a full system, including mesh, primer and topcoat (if needed)?

• Is a topcoat optional or required for performance?

If suppliers cannot provide clear answers to these questions, the risk increases. Coatings should protect steel, safety, uptime and investment.

The adoption of the now UL 1709 Edition 6 and UL 2431 durability standards represents a critical shift toward in-field performance expectations in the region.

Coatings like PPG PITT-CHAR NX system are engineered to meet these challenges head-on, combining certified hydrocarbon fire resistance with superior environmental durability.

For Middle East operators focused on asset longevity, safety, and maintenance reduction, this next-generation PFP system offers a proven solution that aligns with the region’s drive for resilient, cost-effective infrastructure.

* Richard Holliday is the PPG Global Director of Hydrocarbon Passive Fire Protection for Protective and Marine Coatings. He is an industry-recognised expert on fires, explosions and cryogenic spill testing standards. PPG offers holistic solutions for fire, explosion, and cryogenic protection.