Topsoe’s HydroFlex converts renewable feedstocks into high-quality renewable fuels like SAF

Topsoe’s HydroFlex converts renewable feedstocks into high-quality renewable fuels like SAF

For refineries, SAF represents a new and growing opportunity within renewables, and coprocessing is the most practical entry point to take advantage of this increasing market, writes Ignacio Costa from Topsoe

Sustainable aviation fuel (SAF) is a central focus of decarbonisation strategies in the aviation sector, and driving the need for increased production are regulatory mandates and incentives, airline commitments and growing public awareness.

Building dedicated renewable units requires significant capital and time, often in a volatile policy and feedstock environment. Here, coprocessing offers an immediate alternative.

By introducing renewable feedstocks into existing refinery units, SAF can be produced quickly, with modest investment, and without major disruption to operations.

Coprocessing SAF provides refiners with four key advantages:

• Rapid market entry: Using existing assets allows SAF production to start within months, rather than years, making it possible to meet near-term mandates and supply contracts.

• Capital efficiency: Only minor modifications are usually required, reducing financial exposure while still generating compliance and revenue benefits.

• Operational flexibility: Coprocessing allows renewable content to be adjusted in response to market conditions, feedstock pricing and regulatory changes.

|

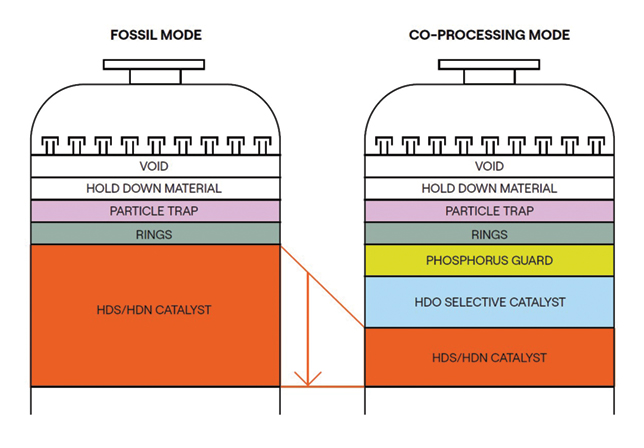

Grading in co-processing of conventional and renewable feedstock |

• Enhanced value creation: SAF attracts premium pricing, and production generates credits and incentives that strengthen refinery economics.

For decision-makers, this combination of speed, flexibility and profitability makes coprocessing a credible strategic option for meeting SAF requirements without overextending capital budgets.

MINOR MODIFICATIONS NEEDED

Refineries frequently choose coprocessing as a practical, lower-risk entry point into the renewable fuels market because it allows them to utilise existing infrastructure with minimal capital investment and shorter implementation timelines.

This approach typically requires only minor adjustments, such as catalyst changes or small hardware upgrades, enabling facilities to respond quickly to evolving regulatory and market demands.

However, technical and operational modifications are necessary to accommodate the distinct characteristics of renewable feedstocks.

For example, hydrogen demand increases significantly due to the higher deoxygenation requirements, while the presence of reactive oxygen molecules generates intense exotherms that must be carefully managed.

In addition, renewable feedstocks increase water formation, increase corrosion risks, and introduce contaminants such as phosphorous, which can accelerate catalyst fouling or poisoning, making catalyst selection critical.

|

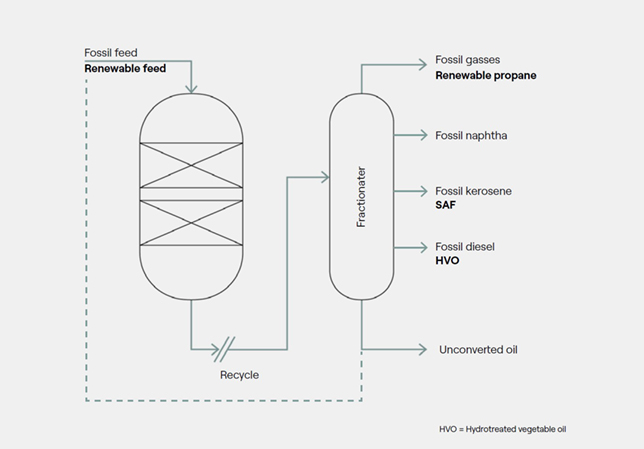

Hydrotreating units may have been the primary choice so far for co-processing of renewable feedstock but hydrocracking units |

On the regulatory side, coprocessing of renewables is limited to 5 per cent by volume when producing SAF from triglyceride-based feedstocks and maintaining product quality –particularly for jet fuel, where freezing point and other specifications are stringent.

This demands precise process control and, in some cases, the use of specialised catalysts for deep dewaxing.

The choice of processing unit is central to SAF coprocessing performance. Kerosene hydrotreaters and hydrocrackers are the most effective, as they are designed for the molecular transformations required for aviation fuels.

With relatively minor changes, they can achieve a high SAF yield.

Meanwhile, diesel hydrotreaters can also be adapted, but most of the renewable feedstock will convert into renewable diesel, limiting SAF output.

Refinery configuration, available hydrogen, and product slate will determine which unit can deliver the most attractive balance between SAF yield and throughput.

Feasible and compliant feedstock blending ratios for use in aviation fuel are defined by ASTM D1655, which specifies strict limits on allowable volumes. Under the current standard, up to 5 vol% coprocessing is permitted for mono-, di-, and triglycerides, free fatty acids, and fatty acid esters. Similarly, a 5 vol% limit applies to hydrocarbons produced from synthesis gas via the Fischer-Tropsch process. In addition, coprocessing, including cofractionation, is allowed for hydrocarbons derived from hydroprocessed mono-, di-, and triglycerides, free fatty acids, and fatty acid esters, with the restriction that no more than 24 per cent of the feed and 10 per cent of the final product may consist of these materials.

HYDRODEOXYGENATION & DEWAXING CATALYSTS

|

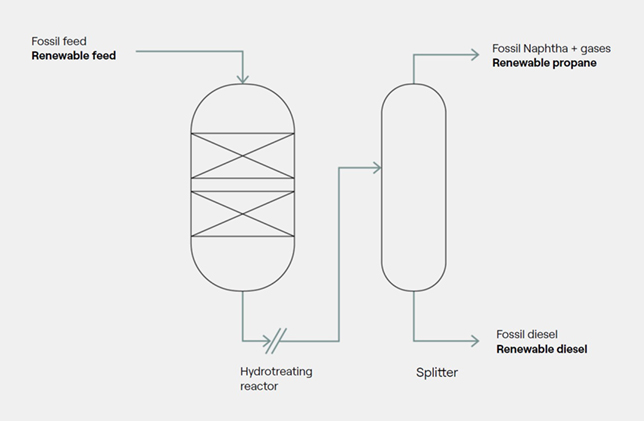

Introducing renewable feedstock into your unit enables your production of a mix of fossil diesel and renewable diesel |

Coprocessing renewable feedstocks requires the use of specialised catalysts, particularly for hydrodeoxygenation and deep dewaxing.

These catalysts are critical for the effective removal of oxygen and contaminants, ensuring that the resulting fuel meets aviation standards.

A key step is the conversion of n-paraffins into i-paraffins, which is essential to achieve the freezing point specifications required for jet fuel.

The dewaxing catalyst must be designed to achieve deep dewaxing while maintaining renewable molecules in the liquid jet fraction.

Topsoe’s TK-930 D-wax catalyst has demonstrated strong performance in pilot-scale testing and is now being applied across multiple industrial operations.

Renewable feedstocks introduce higher levels of contaminants such as metals, which can accelerate catalyst deactivation.

The use of dewaxing catalyst also reduces the available catalyst volume in the unit, which can shorten cycle length.

As a result, catalyst life may be reduced, requiring more frequent regeneration or replacement.

Effective feedstock selection, appropriate pretreatment, and continuous monitoring of process conditions are essential to maintain catalyst activity and maximise performance.

COMMERCIAL OUTCOMES & OPPORTUNITIES

|

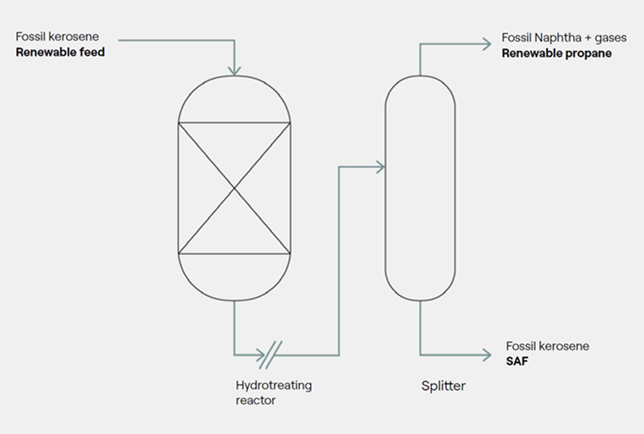

A hydrotreating unit with a splitter in which renewable feedstock has been introduced into the existing unit enabling a production of a |

Coprocessing SAF delivers clear financial benefits. Compliance with blending mandates provides secure market access, while credits and incentives add significant value to production economics.

The payback period for SAF coprocessing is typically short compared with building standalone renewable units.

Exact return on investment depends on unit design, feedstock supply and amount of SAF that can be produced, but the low capital requirement, combined with access to premium markets, makes coprocessing one of the most financially attractive decarbonisation options for refineries.

In addition, coprocessing reduces exposure to fossil fuel volatility by diversifying refinery output.

This positions refineries to benefit from growth in renewable fuel markets while maintaining operational stability.

SAF EXPERTISE & GUIDANCE

Technology, experience and catalyst selection are critical for efficient SAF coprocessing.

Topsoe has been active in renewable fuels since 2004 and has extensive commercial knowhow in SAF. In fact, one-third of all SAF produced globally today uses Topsoe solutions.

The Topsoe HydroFlex™ technology is proven across more than 70 commercial references, and we continue to advance catalyst innovation, including dewaxing systems specifically optimised for SAF production.

Refineries working with Topsoe benefit from comprehensive project support, from feasibility studies and process design through to catalyst supply and ongoing operational optimisation.

Coprocessing gives refiners a technically sound and economically rational pathway into SAF production.

It enables rapid compliance with regulatory mandates, provides operational flexibility and opens access to premium markets with limited capital exposure.

While longer-term strategies for SAF supply will continue to evolve, coprocessing is available now and delivers immediate benefits.

For refinery directors and chief engineers evaluating SAF options, coprocessing represents a decisive step towards low-carbon aviation fuel production, using assets already in place, with technologies and expertise that are fully proven.