ALUCOR has the largest heavy steel fabrication facility in the Middle East covering 50,000 sq m

ALUCOR has the largest heavy steel fabrication facility in the Middle East covering 50,000 sq m

As the UAE accelerates its infrastructure development in power, water, and energy sectors, the company continues to play a leading role in delivering complex, high-impact projects across the region

With over 30 years of global experience, ALUCOR has built a strong reputation across the UAE and Saudi Arabia as a trusted name in industrial engineering, procurement, fabrication, and construction (EPFC) projects.

Renowned for its advanced engineering capabilities and modular construction expertise, the company continues to deliver complex projects with a strong commitment to safety, quality, and excellence.

ALUCOR was founded in 1991 in the UAE as a precision machining company, and has ever since evolved into a trusted name in the Middle East’s industrial landscape.

Today, it delivers turnkey EPFC solutions across the power, water, oil and gas, petrochemical, metals and mining, and renewable energy sectors.

Its mission is to empower sustainable industrial and infrastructure growth while supporting national visions across the region.

ALUCOR established its first manufacturing facility in Jebel Ali, Dubai, one of the world’s busiest ports, in 2003.

Since then, the facility has expanded to cover over 75,000 sq m, evolving into a world-class centre for industrial fabrication.

With direct port access enabling efficient global exports, ALUCOR quickly advanced its capabilities to take on large-scale and complex manufacturing projects.

Alongside this growth, the company has continuously strengthened its expertise by building a highly skilled and diverse workforce across design, engineering, fabrication, and construction disciplines.

Over the past 15 years, this commitment to excellence and innovation has positioned ALUCOR as a trusted leader in delivering some of the region’s most complex EPC projects, setting new benchmarks in quality and performance.

THE ALUCOR ADVANTAGE: EXCELLENCE ENGINEERED

|

The Rabigh 1,200-MW combined cycle power plant |

ALUCOR has been at the forefront of the engineering, procurement and construction (EPC) industry, consistently setting new benchmarks for precision, reliability, and innovation.

Its success is driven by a team of highly skilled professionals, state-of-the-art modular fabrication facilities, and an unwavering commitment to quality and safety.

Strategically located near a major port, ALUCOR ensures streamlined logistics, resulting in faster project execution and minimised delays.

By embracing cutting-edge automation and digital technologies, such as robotic welding and 3D scanning, the company enhances accuracy, boosts productivity, and maintains full control over every aspect of each project.

With a unique blend of time-tested experience and a forward-thinking mindset, ALUCOR is poised to deliver lasting value and exceptional performance on even the most complex industrial ventures.

Its dedication to excellence guarantees results that endure, no matter the challenge.

ACCREDITED FOR EXCELLENCE IN EXECUTION

With a proven track record in delivering complex, large-scale projects, ALUCOR has earned a reputation for operational excellence driven by rigorous systems and processes that uphold the highest standards of quality, safety, and project execution.

Demonstrating both technical strength and a firm commitment to global best practices, ALUCOR maintains an extensive portfolio of international certifications, including ISO 9001, ISO 14001, ISO 29001, ISO 45001, EN 1090-1, ASME U, ASME S, and National Board R.

These credentials underscore ALUCOR’s industry leadership and capability to deliver compliant, innovative, and reliable solutions across the oil and gas, petrochemical, power, and industrial sectors.

A LEGACY OF SUCCESS IN POWER & WATER

ALUCOR brings decades of experience, extensive sector understanding and modular construction to power and water projects.

|

The Hassyan 180-MIGD independent water desalination plant |

These include the manufacture and installation of structural steel, piping, and equipment for leading gas fired power plants, water desalination, and water treatment plants.

Some of ALUCOR’s major projects include the Tanajib 940-MW COGEN Power Plant, Rabigh 1,200-MW combined cycle power plant, a 21-million litres per day (MLD) containerised SWRO desalination plant at NEOM, Shuaibah3 130-million imperial gallons per day (MIGD) SWRO desalination plant, Jubail 3B 125-MIGD independent water desalination plant, Hassyan 180-MIGD independent water desalination plant, Shuweihat4 70-MIGD independent water desalination plant, NAQAA UAQ 150-MIGD independent water desalination plant, DEWA 40-MIGD desalination plant, and several others.

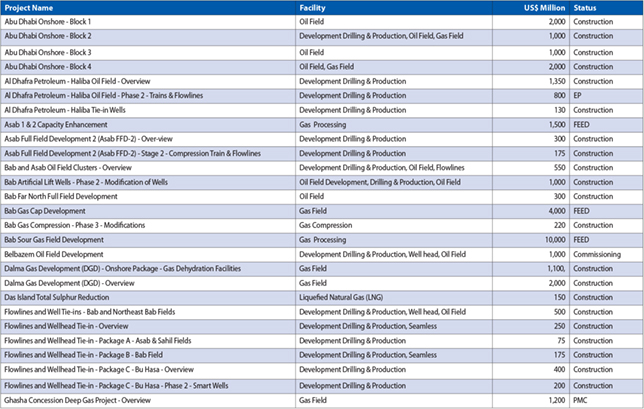

ONGOING PROJECTS IN UAE

As the UAE accelerates its infrastructure development in power, water, and energy sectors, ALUCOR continues to play a leading role in delivering complex, high-impact projects across the region.

With a strong presence in EPC, ALUCOR is currently executing several landmark projects that are critical to the country’s sustainable growth:

• Al Dhafra 1000-MW open cycle power plant, Abu Dhabi: At this major power generation facility, ALUCOR is undertaking the EPC of six water and oil storage tanks.

The scope includes comprehensive civil works, mechanical equipment erection, piping, electrical and instrumentation installations, as well as testing and commissioning.

These tanks form an essential part of the power plant’s infrastructure, supporting reliable energy production for the region.

• West to East Pipeline (WEP) Project, Abu Dhabi: In support of the UAE’s strategic gas transmission network, ALUCOR is delivering engineered surge relief skids as part of the project.

The scope covers engineering, procurement, manufacturing, and delivery to multiple locations. These skids are vital for pressure control and system safety, ensuring uninterrupted and efficient gas transport across the country.

• Hassyan 180-MIGD independent water desalination plant, Dubai: As part of one of the largest desalination initiatives in the region, ALUCOR is responsible for the engineering, procurement, fabrication, installation, and commissioning of four large-scale API 650 potable water storage tanks.

Each tank has a net capacity of 102,300 cu m, with dimensions of 82 m in diameter and 20.4 m in height and features an aluminium dome roof.

These tanks are integral to the plant’s capacity to deliver 180 MIGD, supporting Dubai’s long-term water security.

Through its commitment to quality, safety, and technical excellence, ALUCOR continues to contribute to the UAE’s national development goals, delivering infrastructure that powers communities and supports sustainable growth across the region.

POWERING SUSTAINABLE INFRASTRUCTURE

As the region advances its industrial and infrastructure goals, ALUCOR remains a reliable partner in executing complex, high-impact projects.

With a proven track record and a forward-looking approach, the company is actively shaping a more resilient and sustainable future for the Middle East.