Employing tools and processes, such as digital twins, AI-enabled project control, and improved construction will convert the whole definition of the traditional EPC industry, Aashi Mishra from Research Nester tells OGN

The global energy industry is transforming right before us. When a major Gulf refinery suffered a weeks-long commissioning delay, it was not due to the pipeline fitters but rather because of mismatched engineering models, late procurement updates, and manual handovers between contractors.

Today’s oil and gas engineering, procurement, and construction (EPC) firms are solving exactly that problem by digitising the project lifecycle.

But now the industry is standing at the complicated cross-border of rising hydrocarbon demand and taking efficient methods to decarbonise.

As the International Energy Agency (IEA) confirms that natural gas emissions rose by around 2.5 per cent (180 Mt CO2) in 2024, becoming the largest contributor of CO2 emissions, the question transforms from whether the EPC model must change to how.

The answer lies in a profound transformation, one that leverages digitalisation, embraces efficiency, and navigates the complex path toward a lower-carbon future.

EPC IN THE EVOLVING ENERGY TRANSITION LANDSCAPE

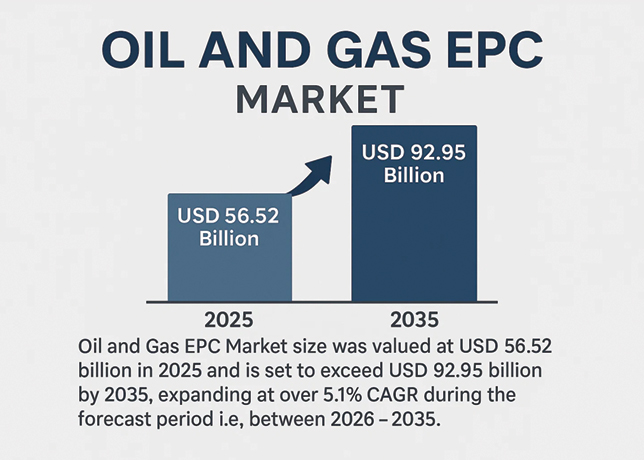

The global energy demand increased by more than 2.2 per cent in 2024, the fastest in a decade, and the energy transition increases investment in developing midstream and downstream infrastructure that keeps EPC activity robust.

|

Energy agencies project large, sustained capital flows into energy systems as nations adapt generation mixes and expand export infrastructure; these investments make EPC execution efficiency a strategic priority for owners and investors alike.

Concurrently, intense pressure from governments, investors, and the public to reduce the industry’s carbon footprint has made sustainability a central pillar of project planning.

According to the International Energy Agency (IEA), the global energy sector is the source of around three-quarters of greenhouse gas emissions today.

Government policies are actively shaping the oil and gas EPC industry, fuelling the transition.

For instance, the Inflation Reduction Act in the US is providing hefty incentives and investing in the infrastructure of carbon capture, utilisation, and storage (CCUS) and clean hydrogen.

In this regard, McDermott International and Baker Hughes are actively collaborating on integrated CCUS solutions.

The US Department of Energy has announced billions in funding for these technologies, creating a new revenue stream for EPC firms adept at complex process engineering.

Additionally, over 140 countries, including major economies that cover Canada, the UK, and those in the EU, have set net-zero targets.

This is forcing national oil companies and international majors to invest in decarbonising their existing assets.

DIGITISATION OF OPERATIONS ACROSS INDUSTRIES

One of the most substantial recent trends in the EPC industry is the adoption of different digital measures for smoother and hassle-free operations.

|

It not only reduces the hectic paper drawings and clumsy PDFs, but it also provides a seamless blend of engineering innovation and data-rich threads.

EPC contractors often have to make complicated calls in large-scale projects to comply with government mandates, to protect the environment by not compromising efficiency.

This work has never been this easy until now. The industry is leveraging powerful tools to streamline processes:

• Adoption of digital twin: Digital twin has come up as a boon to the EPC industry, creating a juxtaposition of as-built reality, operational telemetry, and design intent.

With this tool, it becomes easier to hand over the groundwork as it reduces the need for rework and provides a predictive analysis of the design.

The EPC contractors make the design virtually first, integrating superior 3D models with engineering information.

This makes the operation more fruitful and faster. One great instance is Shell’s Prelude FLNG facility, one of the world’s largest offshore platforms, which utilises a digital twin to optimise operations and enhance safety in a remote location.

Major EPC vendors and operators are publishing case studies that show measurable schedule and opex benefits when digital twins underpin design and commissioning workflows.

For instance, Worley recently published use cases around digital twins for sustainable transformation and EPC 4.0 enablement, illustrating vendor ecosystems that stitch engineering, reality capture, and operations data together.

• AI and cloud collaboration: The traditional way of EPC was in silos that created two different systems for procurement and P&IDs, and a spreadsheet for construction schedules.

Cloud-based platforms, which are offered by Hexagon PPM and Autodesk, are now standard. These platforms unify the schedule, time, and cost, which helps the contractors to have a real-time look at the health of the project.

Recent partnerships between EPC contractors and digital platforms, for instance, Cumulus Digital Systems and Bechtel’s joint venture to deploy a bolted joint management system, demonstrate reductions in punch-list items and commissioninag time.

• Advancements in offsite construction: The updated version of EPC works on modularisation due to multiple factors, including cost efficiency, bridging labour shortages, and enhancing efficiency.

This includes developing standardised facilities and transferring and assembling on time, particularly supporting the logistics.

Aker Solutions, a global EPC firm, invested a hefty amount in these projects in Norway.

By developing intricate topsides in modules at its yard, it dramatically mitigates the risk and cost of offshore projects.

This method also significantly enhances worker safety by moving complex tasks away from a live construction site.

Further, the company also delivered the 5,000-tonne additional module for Equinor’s Johan Sverdrup riser platform in July 2021.

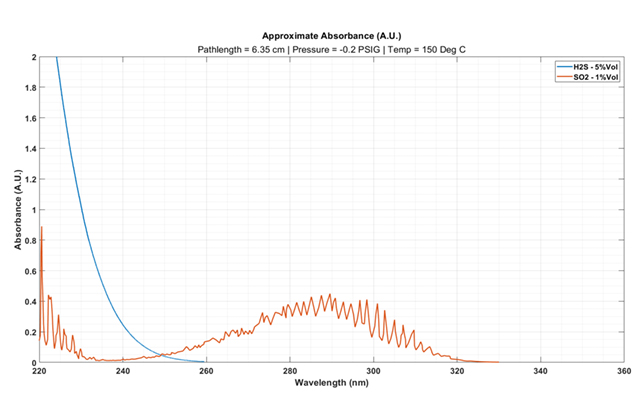

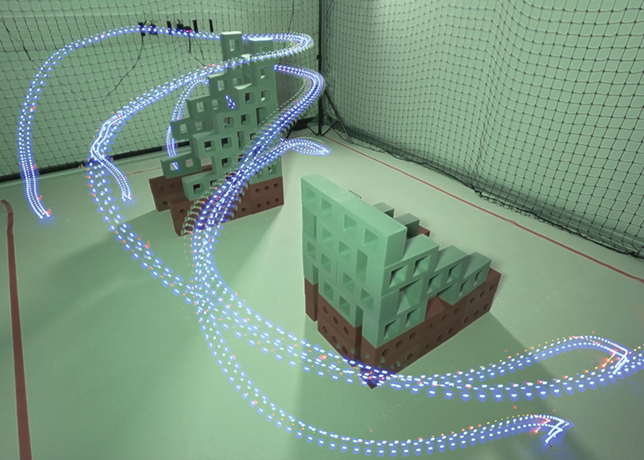

• Inculcation of automation and robotics: For better project monitoring and surveying of areas, the EPC contractors now use high-performance drones, robots, and automated surveying machines that are equipped with high-resolution cameras and AI solutions.

Mapping of an area used to take months manually, which drones perform in a few hours and provide a 3D description as well.

These capacities increase efficiency and reduce the need to visit the site multiple times.

• The Emergence of EPC 4.0: The inculcation of multiple digital tools brought in the inception of a new era of EPC 4.0.

Coined in parallel with Industry 4.0, EPC 4.0 represents a fully integrated, data-driven project delivery model.

It provides seamless sharing of data in different systems, provides real-time access to project information, and helps EPC contractors to get all levels of insights.

Digital workflow has a number of advantages in upstream projects, such as limiting rig-up times, enhancing supervision of materials, and being imperative where movement costs are expensive.

Pipeline projects get a huge advantage from spatial digital twins, which conjoin the survey data with predictive maintenance of the construction site.

This is the future of EPC that looks empowering with having digital twins, AI-enabled project control, and improved construction, and will convert the whole definition of the traditional EPC industry.

EPC digitisation principles transfer to power plants, hydrogen plants, and CCUS facilities, projects that are increasingly co-located with oil and gas assets.

Digitised EPC practices accelerate co-development and reduce interface risk between adjacent projects, enabling integrated energy complexes.

JOURNEY AHEAD

Digitisation in oil and gas EPC is not a tech fad; it’s a structural improvement in how capital projects are planned, bought, built, and operated.

The journey to EPC 4.0 is a strategic imperative. By harnessing digital twins, AI, and modularisation, EPC firms can deliver the capital projects the world still desperately needs.

Oil and gas EPC contractors are not building infrastructure; they are carving the history of the future energy transition.