Karan ... promising ample non-associated gas

Karan ... promising ample non-associated gas

AS SAUDI ARABIA’S industrial base expands, Saudi Aramco is sharply expanding its natural gas production to support future domestic needs for gas to generate electrical power and provide feedstock for new petrochemical projects.

The Karan gas field, the company’s first offshore non-associated gas project, is a major component of that push.

Over the next two years, that demand is expected to increase several times over. By 2013, Saudi Aramco expects the Karan project will be supplying 1.8 billion cubic feet per day (bcfd) of that vitally needed gas. To accomplish this important goal, the company is combining decades of engineering and construction expertise with the latest technologies.

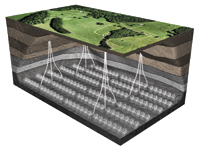

Located far offshore, the Karan gas field will be served by four wellhead complexes using 20-inch offshore pipelines that tie into an 85-km, 38-inch subsea pipeline.

That pipeline goes to the Khursaniyah Beach Isolation Valve and Chemical Injection Station before continuing onshore for about 25 km to the Khursaniyah Gas Plant, where the gas will be processed for distribution.

The offshore projects were awarded to Jay Ray McDermott in March 2009. The engineering phase was completed in February 2010, and the steel work for the phase I start-up, which includes the tie-in platform, one wellhead platform and an auxiliary platform, started in September 2009 and was completed in December 2010.

Work on the phase I installation started in January 2011. The phase I installation was completed on July 6, 2011, and now produces 400,000 scfd. Manifa Development/Karan Upstream Development Department is the operating organisation and has been involved since the start of the project.

The department’s involvement increased significantly during the pre-commissioning phase, when a team of 21 employees was established from different fields, including maintenance technicians, operators, engineers and training evaluators.

An acceptance committee also was established, and departmental employees teamed up with representatives from inspection, loss prevention, fire protection, power operations, marine, project and Northern Area Oil Operations (NAOO) departments to ensure completion and readiness of the facility for commissioning and preparation of systems for startup.

Pre-commissioning started in October 2010 at the contractor fabrication yard and continued after the offshore installations. Following the completion of the Phase 1, the commissioning phase had started with leak testing of the piping system and function testing of the components of the system.

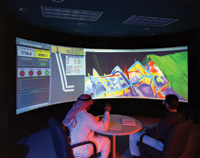

The commissioning team worked long hours to complete commissioning and startup procedures, operator instruction manuals, special instructions manuals, operator checklists, leak test procedures and emergency response procedures. Extensive cooperation and support from other NAOO departments, loss prevention, marine, aviation and fire protection was coordinated through workshops and procedural reviews. To assure readiness of a competent workforce for offshore gas fields, NAOO organised a special training programme for offshore gas operators.

The nine-week programme created certified field service operators after completing this Karan specific training programme both with classroom study and on-the-job training. As the company’s first offshore gas field, both operational and maintenance issues have created huge challenges.

Key challenges faced in operating and maintaining the kingdom’s first offshore non-associated gas field included frequent scraping activities which are needed to remove condensed water from the 38-inch subsea pipeline during early operations. It involves complex material logistics, coordination with Khursaniyah Gas Plant, extensive safety precautions to open scraper traps and system line-up to send scrapers through the line.

In May this year, Aramco announced the successful completion of new gas treatment facilities in Khursaniyah a few weeks ahead of schedule, as part of the second phase of the Karan project. The new facilities can treat 1 billion bcfd from the field. Two more units will be in full operation shortly, increasing the amount of processed gas extracted from the field to 1.8 billion bcfd by 2013.

.jpg)