Khan ... ‘quality is crucial’

Khan ... ‘quality is crucial’

AES Arabia, a total water and waste water management and solutions provider, is in the process of implementing an aggressive expansion plan for its business in the Mena region.

“In addition to our offices in the US and Europe, we are in the phase of implementing a planned expansion of our business in the Mena region,” says Asad Iqbal Khan, manager, international sales and business development at AES Arabia.

AES Arabia offers custom design manufacturing, turnkey execution, project management and operations and maintenance (O&M) services to its clients in various sectors ranging from municipal, commercial, industrial to oil and gas, petrochemicals as well as power.

With offices in several parts of the world, AES’ regional headquarters and its manufacturing facilities are located in Riyadh, Saudi Arabia. AES occupies an 18,000-sq-m fully equipped manufacturing and warehousing facility in Riyadh area. This facility is probably the largest of its kind in the Middle East region.

The water and waste water management company has an affiliation with American Water Chemicals (AWC), a subsidiary of American Engineering Services, US.

“Our exclusive specialty chemicals for all water treatment applications, are manufactured in our plant in Riyadh with the expertise provided by AWC,” says Khan.

The manufacturing facility for speciality chemicals consists of all the necessary equipment to ensure that highest degree of quality is maintained during the production. The operating procedures and processes are designed to ensure complete safety of operating personnel and are environment friendly, says the company.

“The well-equipped laboratory not only ensures quality control but also facilitates product development/ modification depending on client/ application requirement with the direct supervision of AWC. Our skilled and trained operating staff is supervised by well experienced chemical engineers and chemists,” explains Khan.

Being certified to the highest international standards of quality ISO 9001:2008, ASME and NSF, AES has established high quality objectives to ensure full satisfaction of its customers ensuring highest quality standards in its work, as well as the implementation of the highest international design codes.

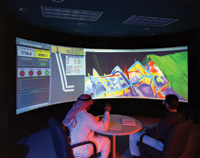

Among its prestigious clients in the Middle East and the rest of the world are Saudi Aramco, Adnoc, Sabic, PDO, Sonatrach, National Oil Production Company of Egypt (EGPC), Syrian Petroleum Co, Total and many more in oil and gas and petrochemical concessions. In addition, AES has been working with some of the major EPC companies over the past two decades, such as Bechtel, Saipem, Technip, JGC, Samsung, SKEC, HDEC, Petrofac and Daelim and others.

As part of the projects undertaken by the company, AES has been given appreciation award from JGC Yokohama for the successful start of a 28,000 cubic metres per day (cmd) sea water reverse osmosis (SWRO) plant for Tanajib sea water treatment facility in Manifa central area where JGC was the main contractor and the end user is Saudi Aramco.

“We are executing projects for the Shaybah LNG project and the Wasit Gas mega projects with Samsung Engineering and SKEC to design, manufacture and supply high brackish water reverse osmosis (HBRO) plants and chemical injection skids,” says Khan.

The company has also secured a $14-million contract to design, manufacture, construct, commission and start-up a dedicated SWRO plant that can produce up to 2,752 gallons per minute (gpm) of fresh water for the King Abdullah University of Science & Technology (Kaust) Research Park.

The contractor for this project is China National Chemical Engineering Company (CNCEC) under the management of Saudi Aramco. AES Arabia was selected in competitive bidding based on its track record and due to its long work experience with Saudi Aramco.

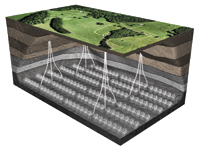

Under this contract, the source of seawater will be from deep open intake and shall be extensively pre-treated before it is pumped into the desalination plant. The desalted water will be further treated for the removal of Boron and consequently re-mineralised to meet the WHO standards. Although built for a research institution, the plant design and manufacturing will be according to the stringent standards followed in all Saudi Aramco oil and gas projects.

AES Arabia previously built an 8,000 cmd MBR sewage treatment plant and participated in the construction of the 52,000 cmd SWRO for Kaust.

According to Khan, residents of many cities in the Middle East enjoy millions of gallons of fresh and potabilised water produced by AES supplied desalination systems.

Power plants, airports, oil and gas plants, military bases and many other industries in numerous locations use AES water treatment systems to meet their process needs or to treat their effluent in compliance with the ever increasing and stiff environmental regulations.

.jpg)