Asiree ... technology focused

Asiree ... technology focused

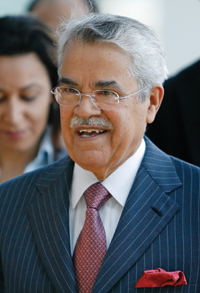

AL QAHTANI Maritime (AQM), one of the leading Saudi companies providing oil, gas and water drilling equipment and services, says it is all set to uphold its lead in the upstream arena by continuing to focus on technology and innovation.

The company, which is a part of the Abdulhadi A Al Qahtani Sons Group, plans to focus on future growth by pursing its tried and tested strategy of introducing new products and services through acquisitions and joint ventures.

“We believe that solid growth demands sound technology and excellent service; we plan to provide both by capitalising on expertise and history of our future partners,” says Hassan Asiree, the general manager of Al Qahtani Maritime. “The strategy has delivered results for AQM in the past and produced successful joint ventures (JV) such as Saipem Saudi Arabia Company (a joint venture with Saipem) and Arabian Minerals & Chemicals Company (a JV with MI-Swaco).”

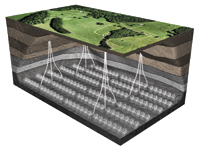

Since its inception, AQM has become a platform for advanced technologies, strategic alliances and precise operations in order to reach the highest level of excellence, both through its products and services. AQM provides services to three industrial sectors: oil, gas and water with reliable drilling solutions that maximise efficiency, minimise cost and eliminate risk in the field. The company is the exclusive agent of leading international brands like TIW (Texas Iron Works), NOV ReedHycalog, WRT, Croda, and ECS Global, which supply to major oil and gas companies such as Saudi Aramco with their drilling and engineering services requirements.

FOCUS ON JVS

AQM has invested in various companies that have distinguished offerings in the oil and gas sectors such as Saudi Arabian Saipem, Arabian Minerals & Chemicals Company, Gulf Salt Company and the National Factory for Can Ends (Nafcel).

Business alliances with international companies such as TIW Corporation, NOV ReedHycalog, WRT and Tekab has balanced the growth for AQM. All these international companies are renowned for establishing world-class technology for the oil industry and these partnerships have ensured that AQM maintains quality in the industry.

FUTURE PLANS

Going forward, Asiree says that the company has identified several areas of growth and in each of these plans to explore and develop partnerships to bring technology and expertise to the Saudi market with an aim to localise manufacturing and services.

|

|

AQM ... a platform for advanced oil and |

“Our commitment to the Saudi economy is to transfer technology and maintain the highest levels of Saudisation by training local manpower and developing locals through all levels,” says Asiree.

Among several practices identified by AQM, Drilling Equipment and Services is still a major core practice. In this area, AQM has recently added a new joint venture with Sledghamer Oil Tools to locally manufacture downhole tools and equipment in Saudi Arabia. In the second strategic core practice identified as Specialty and Performance Chemicals, AQM has partnered with two of the world leaders in specialty chemicals: Croda, which is a world leader in natural based specialty chemicals, and WRTBV, which provides best-in-class additives for oil and refined products to enhance its performance and physical properties.

In the third and most important core area, Corrosion Management, AQM is in the final stages of launching a new joint venture with a technology leader to install two state-of-the-art service facilities in Saudi Arabia. Through the proposed joint venture and the facilities, AQM plans to introduce new technology in corrosion management for the first time in the region and maintain a leading R&D (research and development) facility that can meet the ever-increasing requirements of the oil and gas market in Saudi Arabia. “This JV will be announced before the end of this year once all permits are granted,” says Asiree.

In the long run, AQM’s business objective, says Asiree, is to double its operations in Saudi Arabia in less than five years while maintaining a strong commitment to:

• Hire more Saudis across all aspects of its operation;

• Transferring technology to maintain its lead in the upstream arena; and

• Creating sustainable wealth for its shareholders.

AQM, represented by its board of directors and staff, continues to offer its unwavering commitment to reach this objective, he adds.

Meanwhile, AQM business development manager Nouman Naseem highlights some of the latest products AQM is offering from two of its partners, TIW and NOV Reed Hycalog.

“TIW has been engineering custom solutions for drilling and completion tools for more than 95 years,” he says. “From safety and kelly valves to liner hanger systems and completion tools, TIW is a leader in introducing innovative technologies and tools to the oil and gas industry.”

X-PAK – ADVANCED LINE HANGER

He continues: “The X-Pak expandable liner hanger, which has been in development at TIW for over six years, is designed to provide a true 360-degree metal-to-metal, gas-tight liner seal in high-temperature, high-pressure well environments.

“The ultra-slim design of the X-Pak also provides a greater annular bypass area, helping to lessen the ECD effect. This advanced liner hanger boasts superior burst and collapse characteristics and allows for rotation and reciprocation.”

Other new technologies introduced by TIW – which has a long history of engineering new and innovative tools for the drilling and completion needs – include the CPT (casing pulling tool) and the CTO (casing-tubing opener), Naseem says.

“The CPT is a downhole hydraulic jacking system that allows casing recovery operations. These tools are currently being utilised in the North Sea for slot recovery and can be used for fishing applications as well,” says Naseem. “The CTO is also a downhole hydraulic tool designed and field proven for opening collapsed tubing and casing.”

ADVANCED DRILL BIT TECHNOLOGY

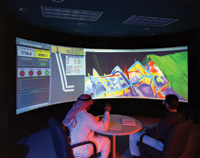

Moving on to NOV ReedHycalog, Naseem says AQM has been supplying the company’s drill bits to Saudi Aramco for over four decades.

“NOV ReedHycalog continuously focuses on research and development and technology advancement and AQM has introduced number of its new products to Saudi Aramco which proved their worth in the following areas of operation,” he says.

• Advanced cutter technology: A 16-inch DSR816M, SN E150261 achieved field longest interval drilled, fastest ROP (rate of penetration) and lowest CPF (cost per foot) record for Saudi Aramco in Manifa field, onshore Saudi Arabia, in the first quarter of 2012;

• System-matched directional solutions: A 6-inch RSR613S, achieved the highest ROP record and lowest CPF for Saudi Aramco in Abu Safah field, offshore Saudi Arabia, in the third quarter of 2012; and

• Large diameter solutions: A 22-inch T41 achieved a new ROP record of 79.9 ft/hr and a low CPF compared to similar runs drilling interval with more than 2000 ft, at Aramco’s Abqaiq field in Saudi Arabia, during the second quarter of 2012.

OBJECTIVES

Elaborating on the role of the 22-inch T41, Naseem continues: “The objective was to vertically drill the 22-inch section from RUS formation (Anhydrite) to +/- 50m into Ahmadi (limestone) run at the best possible ROP whilst maintaining a good wellbore quality in one bit run,” he says.

“The 22-inch T41 bit S/n D158947 was run to drill through heterogeneous formations from 520 ft (RUS) to 3,275 ft (50 ft into Ahmadi).

“The bit drilled a section of 2,755 ft in 34.5 total drilling hours achieving an average ROP of 79.9 ft/hr. The bit was dull graded as 2-2-BT-CM-E-I-TD.”

RESULTS AND BENEFITS

The 22-inch T41 bit achieved the following results, he says:

• 51 per cent faster than the best competitor offset;

• 46 per cent increase in ROP; and

• 28 per cent decrease in CPF compared to the best offset runs drilling a similar interval with more than 2,000 ft.

The benefits, he points out, were:

• Increased load carrying capability and longer bearing life;

• Low torque - reduced seal friction and longer life;

• Superior gauge durability;

• Reduced bit body wear and enhanced stability;

• Improved gauge protection; and

• Superior abrasion resistance on teeth.

.jpg)