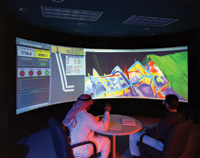

A reservoir simulation in progress

A reservoir simulation in progress

GIGAPOWERS – a Saudi Aramco technology unveiled in 2010 – is the second generation of the company’s reservoir simulator, Powers (parallel oil, water and gas enhanced reservoir simulator).

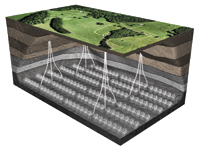

A simulator describes the oil, water, and gas flows inside the porous rocks that contain hydrocarbons.

To do this, relevant physics, chemistry and thermodynamic relationships are integrated as highly complicated mathematical equations.

The solutions to these equations are presented in grid blocks, or cells, that create a detailed visual picture of an oil field.

Simulations are used in all aspects of the oil industry including calculating the optimum number of wells to drill, the placement of those wells, estimating facility specifications, calculating reserve depletion and designing reservoir management strategies.

In the past, frustratingly low resolution meant that the obtained reservoir images contained only limited detail.

Take a digital camera – the higher the number of pixels, the clearer and more accurate the image.

In reservoir simulations, the “pixels” are called “cells,” and pre-GigaPowers technologies severely limited the number of cells that could be characterised.

Until the 1990s, Saudi Aramco industry-standard simulators used a single computer CPU (central processing unit), limiting the scope of the simulation to only 50,000 reservoirs cells.

This meant that large reservoirs had to be divided into very large grid blocks and resulted in very coarse descriptions that ignored the heterogeneous properties of the rock within the field.

“Higher resolution grid blocks were necessary to overcome these limitations – and not just a few tens of thousands, but several orders of magnitude more cells,”explains Mohammad Al Qahtani, executive director of Petroleum Engineering and Development.

“The problem was being able to process such huge volumes of information in a timeframe even vaguely useful for our reservoir engineers’ requirements.

“One pessimist at the time suggested that even if it could be built, running such a mega-model would take years.

“In fact, the reservoir would be depleted before the simulation finishes!” he claims.

|

|

The Saudi Aramco team at Expec Arc |

But not to be thwarted by technological challenges, a team within Saudi Aramco Exploration and Petroleum Engineering Centre’s Advanced Research Centre (Expec Arc) was created and assigned these new goals.

The first generation Powers development team, headed by Dr Ali Dogru, now chief technologist of the Computational Modelling Technology (CMT) Team at Expec Arc, began developing the company’s new reservoir simulator in 1994.

The team has grown and has been breaking records ever since.

By 2000, they broke the one-million-cell record by designing the simulation to run parallel on hundreds of CPUs simultaneously.

The first milestone was the successful visual characterisation of 30 years of production injection performance from the Berri/ Hadriya reservoir.

That equated to 1.3 million cells with 74 vertical layers, run in just a few hours.

Following the Berri/ Hadriya model, Safaniya, Zuluf and Abu Safa were also simulated.

In 2002, the 10-million-cell milestone was achieved with the first full-field simulation of the Ghawar field, Saudi Aramco’s largest and the world’s largest field, which produces roughly 5 million barrels of oil a day.

But, still, the Powers team aimed higher.

“Our next goal was to increase the capacity of the simulator from 10 million cells to 100 million cells by 2010,” explains Samer S AlAshgar, Expec Arc manager.

“That was thought to be an ambitious goal – a 10-fold increase in model size.” But bigger challenges still faced the team.

Billions of cells were required to render Saudi Aramco’s giant oil and gas fields at seismic or near seismic resolution.

“No one in the industry was talking about that sort of capacity. There wasn’t even a name for it. So we decided that not only would we create a billion-cell model, we would do it in the same timeframe as we originally intended for the smaller model – by 2010. And that is how GigaPowers was conceived,” AlAshgar continues.

In 2009, the Powers team broke through the billion-cell, or giga-cell threshold. That advancement is already delivering results for Saudi Aramco’s reservoir management.

Mega-cell simulations of Ghawar and other giants can be completed in less than a day and provide the reservoir management team with unprecedented confidence in their ability to optimise giant field production.

GigaPowers can accurately locate oil that was overlooked by earlier coarsegrid simulations if there is any.

Additionally, in the Shaybah field, the ability to simulate at finer grid spacing makes it possible to plan complex wells, placing each lateral in optimal locations.

These are not the only benefits of the superior processing capabilities of GigaPowers.

The gains in accuracy and productivity achieved by having detailed and fast simulations have substantially raised the bar in optimising development of the largest oil and gas reservoirs in the world.

The journey will continue for the professionals of Expec Arc’s computational modelling team.

They have already set their sights on a raft of new goals. One of these aims to connect GigaPowers to Saudi Aramco’s I-field (intelligent field) centres, the central receptacles where all data relating to an oil field’s operations is received and processed.

Real-time or on-line simulation using I-field data allows for much more accurate management of the reservoirs. In petroleum refineries, computer programs like GigaPowers manage the refining units in obtaining the best yield of gasoline and other products made from the crude feed by adjusting control devices for each refining unit.

In petroleum engineering and I-field applications, GigaPowers will be doing the same, supporting reservoir management decisions with recommendations to adjust remote-control devices placed in wells to control aspects like water or gas production.

“With numerous reservoir aspects to manage, our team has developed a user-friendly product with unique features such as a sound-enabling alert system. For example, there is always a risk that water or gas fingers might break through into wells. In such an instance the simulator may issue the following audio instruction: ‘A water finger will reach well number five in two months. Suggestion: schedule a work over operation,’” illustrates Dogru.

Another goal is to meet the industry’s ever-present need for simulation speed. So far, CPUs have done all the work in high-performance computing. However, despite CPU speeds nearly doubling every six months over the past decade, peak speeds will be reached in just a few years.

Expec Arc is studying ways of maximising computing hardware to accommodate the continuing demand for improved computing speed. Graphical Processing Units (GPUs) are the new frontier. Traditionally used for video games, they can also be used for numerical computations. Studies have shown that GPU is faster than CPU by several orders of magnitude. However, there are issues. GPU cannot work alone, still requiring CPU power.

This poses several problems. One, the GPU programming language is complex and not currently compatible with CPU. Software companies have begun working on new compilers that will allow engineers to write computer codes using their conventional languages to translate those languages into GPU language.

Another issue is creation of a combined CPU-GPU architecture that supports data transfer between the GPU and CPU.

The Expec Arc Computational Modelling Team has already proven they are industry leaders, and it won’t be long before these challenges inspire a wave of new groundbreaking achievements.

.jpg)