Hatoum ... ensuring quality control

Hatoum ... ensuring quality control

UNITED Maintenance & Contracting Company (Unimac) is a specialised engineering and contracting company established in Riyadh in the 1970s, focusing exclusively on the design, construction and maintenance of infrastructure.

From the asphalting of roads, highways, airports and general infrastructure, Unimac is a vertically integrated company with control of all raw materials, laboratory testing and transportation to ensure quality delivery on time for its clients.

With its staff of 800 employees and 650 separate items of high-end plant and equipment, Unimac has a high reputation with a proven track record achieved over more than three decades in executing turnkey projects ranging from airport infrastructure to roads, inter-city highways to new urban developments. Unimac operates under internationally recognised project management and quality control organisations such as ASTM, ACI, ISO 9001-2000 and the International Road Federation.

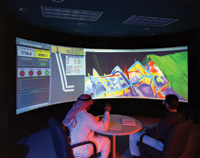

From the design of intercity highways to housing projects infrastructure, landscaping to hardscaping, Unimac employs surveyors, CAD designers, architects and engineers who work side-by-side with clients to provide expert value-engineered solutions.

Its impressive client list includes top contractors such as the Saudi Binladin Group and El Seif, ministries, municipalities, universities, General Authority for Civil Aviation, Royal Saudi Air Force and many others in the public and private sector. Unimac’s landmark projects include the Princess Nora bint Abdul Rahman University in Riyadh (road infrastructure work), King Khaled International Airport (infrastructure work), Abu Bakr Road in Riyadh and King Saud University (infrastructure work).

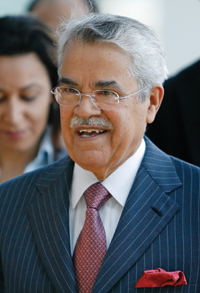

Fadi Aristo Hatoum, general manager of Unimac, assumed the top management role in 2006 when he took over the daily running of the company from his father, Aristo Hatoum. Hatoum Senior established the company in the 1970s and as chairman continues to play an active role in the development of Unimac as the company looks to expand into the Western Province.

Last June, Unimac opened offices in Jeddah with aggregate facilities near Rabigh as part of a wider strategy that will also include capacity expansion into the Eastern Province, as the company establishes its aggregate plant at Saman about 180 km from Dammam.

“Unimac is well established in the Central Province with an excellent reputation but we can see phenomenal growth in the Western Region with infrastructure, housing projects, large educational facilities and developments in Yanbu and Rabigh. Similarly, we are looking to progressively develop Unimac in the Eastern Province too,” Hatoum says.

|

A worker at a Unimac facility |

Unimac has built its considerable reputation by specialisation and operating within a highly structured vertically integrated organisation with attention to detail that covers all aspects of the company’s activities from the production of basic raw materials, quality control, laboratory testing, transportation to project execution. In terms of scale and capacity, on the recent fast-tracked Princess Nora University project in Riyadh, Unimac supplied and executed 3,000 tonnes per day of asphalt during the compressed contract period.

Unimac’s reputation for delivering premium quality asphalt reflects the reliability and longevity of the material to withstand the high traffic loads and temperature fluctuations.

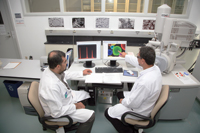

According to Hatoum, many of the asphalt mixes and formulations have been designed and developed in-house and approved for municipal projects and the Ministry of Transport (formerly the Ministry of Communications).

All Unimac’s asphalt production facilities are calibrated and certified to ensure that clients receive a high quality finished product that matches the mix design. All asphalt quantities are calculated through certified plant weighing systems and again crosschecked on an external 100-tonne electronic weigh bridge.

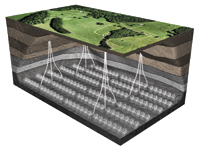

Rock aggregate is also a key raw material that Unimac produces, and is integral in the production of asphalt and concrete. The selection of high quality quarries is implicit prior to installation of the crushers.

Importantly, materials must have low calcium and sulphur content, low abrasive qualities, low water absorption and a high specific gravity. These physical properties are critical to the production of high quality aggregates.

“Over the last five years we have decided to strategically grow the business to cope with increase demand. This involved serious re-investment into the company to acquire new equipment, new sources of raw materials and recruitment of new staff,” says Hatoum.

He continues: “We are in the process of developing more crushing sites for the rock aggregate and will select only the highest quality quarries for mining and extraction. From quarrying to our asphalt and crusher plants, management and control is under Unimac, a quality- assured approach that delivers a premium product and continues to serve the company well.

“Currently we are in the process of opening our first office in Jeddah to serve the Western Region to bring our premium brand across Saudi Arabia. We are also developing our crushing facility at Samam in the Eastern Province about 180 km from Dammam.”

All materials are tested by Unimac’s quality control department at the plant as well as on site, to ensure that the project execution department abides by the most stringent industry standards.

Unimac uses a triple screening process which ensures the removal of almost all harmful dirt and clay from the aggregate during the production. Aggregates are produced with angular edges and in cubic form, suitable for many industrial sectors.

“Unimac can be defined as a medium-size company and we had a turnover of SR140 million ($37.28 million) in 2011. We operate to strict margins and look to grow our capacity in a measured way. One might say we are risk-averse as we have always been very selective in our business approach.

“It is easy to win contracts during a construction boom, but our approach is always on quality products and workmanship and delivery on time for any project, and Unimac will not compromise on this. I am a man of detail like my father who taught me that a job must always be executed right the first time,” he continues.

As the only son, Hatoum was destined to join the business, having received his bachelor’s degree from the American University of Beirut (AUB) in the 1990s, and a masters in business administration (MBA) from the prestigious Boston University in 2003.

“My father is a man of detail and he taught me the business from an early age,” he says. “When I joined Unimac full time, he insisted that I begin work in one of the testing laboratories at our aggregate production sites in Rumah. I lived at the production site and worked in the quality control laboratory for my first year.

“Looking back at this hands-on experience and working in the lab and production facilities side by side with the employees, taught me a great deal not only in terms of quality assurance but also how to communicate with our staff. This experience has helped develop the company as we look to expand and build capacity.

“From blueprint to handover, we are involved with the clients in the design of the roads and highways. Using a value engineering approach, we ensure that the client gets the most out of their investment.”

“Other contractors focus on winning a contract and getting the job done with a healthy profit. Unimac takes it one step further. Our job is not done until our client is absolutely satisfied,” he concludes.

.jpg)