THROUGHOUT the years, many leading owner operators have chosen Intergraph’s industry-leading SmartPlant Enterprise integrated suite of tools to manage their dynamic engineering design basis. Building on this success, Intergraph has introduced SmartPlant Enterprise for Owner Operators (SPO), offering preconfigured work processes covering the complete plant life cycle, interoperability with maintenance and other operations’ systems, and a common Web portal designed for owner operators.

Owner operators, says Intergraph, face unprecedented demands to deliver new plants and major expansions of existing facilities more rapidly while utilising finite resources; maintain the highest levels of health, safety, and environmental protection; deliver projects on schedule and within rigid budget constraints; manage time-to-market and deliver a high-quality product in a competitive environment; create facilities flexible enough to meet market demands in production and product offerings;

They also have to avoid adversely impacting the functionality of the existing plant while undertaking complex plant modifications; maintain safe, predictable production levels from existing plants, at the lowest sustainable cost; demonstrate to regulatory authorities the integrity of plant-maintained information; provide assurance that the ‘virtual plant,’ in-plant documentation, and IT systems are consistent with the current physical state of the plant in operation; demonstrate that a controlled management of change (MOC) process with auditable traceability is enforced within plant operations; and retain plant knowledge and experience in the face of increasing rates of workforce retirement.

“One barrier owner operators face in meeting all of these challenges is interoperability or the ability to manage and communicate electronic product and project data between collaborating firms and within an individual company’s design, construction, maintenance, and business process systems,” says a company spokesman.

“Owner operators must find a way to address these interoperability issues, while focusing on their core businesses of exploration and production. Intergraph SPO has been designed to help address the issue of interoperability by providing prepackaged solutions that can be rapidly rolled out, incorporating customer-specific requirements at low risk. SPO will support plant owner operators in effectively delivering capital projects and achieving safe, predictable production at the lowest sustainable cost.”

Intergraph SPO supports the execution of capital projects by supporting asset information management and integrated project execution best practice work processes; providing tools to enable collaboration throughout the value chain; and providing a single, central source of truth in projects.

Intergraph SPO supports plant operation by managing engineering change in plants; ensuring engineering data quality and consistency; providing predefined best practice work processes; and offering easy access to information needed to perform work, independent of where data is held.

Management of the ever-changing engineering design basis throughout the plant life cycle is a key success factor for SPO.

INTEGRATION TECHNOLOGIES

SPO leverages leading integration technologies such as SAP NetWeaver and Microsoft SharePoint. These technologies power the synchronisation of data between the engineering design basis and other operations’ systems, including legacy systems, and provide the role-based Web portal.

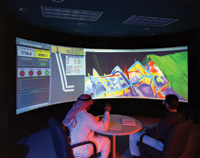

MANAGING CHANGE

SPO offers interoperability between SmartPlant Enterprise and other operations’ enterprise systems. This ensures that information in enterprise resource planning (ERP), reliability, process safety, digital control systems, and more is maintained to reflect change in the dynamic engineering design basis. Information will be presented to the user via a common, role-based Web portal. This portal will filter and structure search results based upon user role and privileges, reducing discovery time and leading to better, faster decision-making.

SUPPORTING ENGINEERING

During the plant design, construction, and completion/startup phase of greenfield or brownfield projects, SPO provides preconfigured processes to support engineering and project execution work processes. These include document and data interdisciplinary review, management of project change, interface management, non-conformities/waiver management, technical queries, and more. These processes are suitable for both Capex projects and turnaround projects.

A secure Web portal promotes easy access to the “single source of truth,” where information and documentation from across the project are assembled in a common, globally accessible repository, eliminating the need for traditional document and data distribution.

COMMON DATA MODEL

SPO is built on Intergraph’s proven, industry-leading, multi-discipline toolset. The SPO core solution includes a site licence for SmartPlant Foundation, SmartPlant Reference Data, SmartPlant Isometrics, and SmartSketch. Other integrated SmartPlant Enterprise tools such as SmartPlant 3D, SmartMarine 3D, SmartPlant Instrumentation, SmartPlant Electrical, and SmartPlant P&ID are licensed separately and can be included as required. These tools are integrated around a common, plant-centric data model and integration hub, ensuring data consistency between tools.

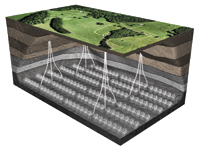

DATA HANDOVER

The handover of data from Capex projects and plant turnarounds can involve the transfer of thousands of documents and millions of individual data items. The handover of a $1-billion Capex project can cost more than $15 million and take more than a year. SPO provides two complimentary solutions that address different aspects of the handover and take-on of data and documentation. These solutions can be both included in a comprehensive information handover strategy to reduce the cost and effort of data take-on.

.jpg)