EPC contractors, main contractors and steel fabricators from across the Middle East region, particularly in Saudi Arabia, the UAE and Egypt are increasingly turning to the StruM.I.S fabrication and information management system from AceCad Software to manage their steelwork fabrication projects.

StruM.I.S delivers significant business benefits for the steelwork fabricator and one of the latest companies to invest in StruM.I.S is the William Hare Group Ltd who recently signed a corporate agreement to purchase and implement StruM.I.S across their global sites, according to a company spokesman.

StruM.I.S is a complete dedicated management information and production system for steelwork companies; to deliver improved cost efficiencies, increased productivity and profitability. The StruM.I.S system harnesses the information flow and work processes through the steelwork contract between job functions, departments, suppliers and clients; from estimate tendering, through procurement and production and into site construction.

StruM.I.S steel fabrication management software is for engineering and steel fabrication companies who are looking to implement a fabrication management information system for superior performance across their business, including multiple sites or even across supply chains.

“Unlike some generic ERP/MRP systems StruM.I.S is dedicated to steel project fabrication and provides a solution for superior management information and production processing. The system delivers a streamlined workflow and connects all steelwork fabrication functions and departments,” the spokesman says. “This leads to many benefits including increased productivity and profitability, time and materials cost savings, improved accuracy and error reduction. Additional benefits are increased efficiency, automation of repetitive tasks, reduced overhead potential and increased project traceability for quality control.”

StruM.I.S system modules include enquiries and estimating, customers and sales, items and inventory control, purchasing and suppliers, contracts management, QS analysis, production control and document management. Superior integration with structural modelling systems and leading CNC machinery manufacturers, accounting and ERP systems, enables companies to connect and harness their processes.

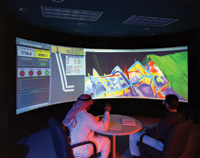

Some of the key aims of the software include workflow and automation advantages leading to greater efficiencies and organisational benefits through systems and processes. With real time tracking facilities via 3D, model multiple project status’s can also be viewed, monitored and controlled more easily.

.jpg)