Increased adoption in the oil and gas indsutry is driving the growth in air compressor market

Increased adoption in the oil and gas indsutry is driving the growth in air compressor market

Worldwide air compressor market is expected to gain increased demand due to recovering world economy. Increasing global investments in upstream and midstream oil and gas will further boost the market, says a report

The global air compressor controller market is poised to achieve a steady 5.8 per cent compound annual growth rate (CAGR) from 2014 to 2022 thanks to their increasing use in industries such as energy and mining, oil and gas, and petrochemicals, according to a new report published by Transparency Market Research.

Valued at $3.45 billion in 2014, the global air compressor controller market is forecast to reach $5.44 billion by 2022.

Key factors driving the growth of global air compressor controller market include efficient compressor operation at lower costs, low maintenance of air compressor, rising adoption of variable speed air compressor controllers, and after-market service and retrofitting of existing air compressor systems. The increase in demand from oil and gas industry is another factor driving the demand for air compressor controllers.

Increasing adoption in oil and gas, energy and mining, and petrochemical industries where compressor controllers are used in production activities, is expected to drive the air compressor controller market. Moreover, extraction of natural gas resources from shale gas reserves is expected to surge the demand for compressor controllers and create potential opportunities for this market.

Based on geographic regions, the air compressor controller market is segmented into North America, Europe, Asia Pacific, Middle East and Africa, and Latin America. In terms of regional adoption, Middle East and Africa, and North America were the key contributors to the global air compressor controller market in 2014. The Middle East and African countries such as Saudi Arabia, Iraq, Nigeria, Libya and the UAE, are the largest contributors in terms of oil production to the global economy. The compression control requirement from these countries is high and thus, the demand for air compressor controller is high in these regions. In North America, air compressor controllers are primarily used in the oil and gas, energy and mining, pharmaceutical, and HVAC industries.

The air compressor controller market is moderately consolidated, however, the impact of regional players is significant in the global market. Key manufacturers in this market are continuously striving to improve efficiency and reliability of air compressors. Some of the key manufacturers of compressor controllers include Siemens, GE Measurement & Control Solutions, Compressor Controls Corporation and Emerson Climate Technologies.

These players are primarily involved in acquiring regional players manufacturing compressor control solutions. Besides offering air compressors with integrated control capabilities, these players also provide retrofitting solutions for already installed air compressors. Other significant players in the market include Schneider Electric, Gardner Denver, Rockwell Automation, Johnson Controls, Petrotech, Ingersoll Rand and FS-Elliot Co.

AIR COMPRESSORS

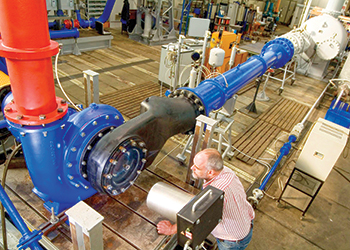

An air compressor is a mechanical device that converts power from electric motor or from an engine into kinetic energy by pressurising and compressing air which releases on quick bursts. Various methods of air compression are positive displacement type and negative displacement type. Positive displacement type of air compressors are piston type air compressors, rotary screw compressor and reciprocating air compressor.

Negative displacement type of compressors includes centrifugal air compressor and axial flow compressor. Positive displacement type air compressors works by pushing air into a chamber whose volume has been decreased to compress the air. Negative type air compressors utilise centrifugal force produced by spinning impeller to increase and decrease air which further pressurises it.

Air compressors are segmented according to the design and principle of operation such as reciprocating type compressor, rotary type compressor and turbo compressor. Reciprocating compressor is further classified such as single stage, two stage, rocking piston type and diaphragm type. Rotary type compressor includes scroll type, rotary helical screw type and rotary sliding vane type

Some of the major drivers of this market are rapid industrialisation and developing economies. However, high operational cost in the manufacturing of air compressors can hamper the growth of the market. Ample opportunities lies for air compressor as large number of industries are coming up in future.

Some of the key players in the business of air compressor are Frank technologies, Bauer group, Oasis Manufacturing, Airtex Compressors, Ingersoll Rand, Bel Aire Compressors, Grainger Company, VMAC Company, Best Aire, and Sullair among others.

CLASSIFICATION

Air compressors can be classified in numerous ways. Based on mobility, air compressors can be stationary or portable. Based on technology, air compressors can be rotary vane, reciprocating, centrifugal, or screw. Based on the requirements of the application, air compressors can be air-cooled, water-cooled, single-stage or multistage, lubricated or non-lubricated, electric driven, or diesel engine driven. Based on the type of lubrication used, air compressors can be oil-based or oil free.

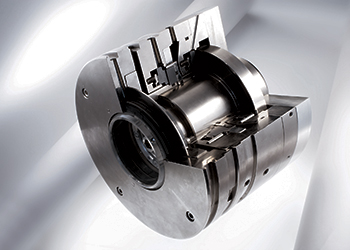

The key raw materials used for manufacturing air compressors are steel, aluminum, and castings. Key finished and semi-finished components used in air compressors include crankshafts, bearings, switches, rotors, gauges, and housings.

The key capital equipment used for manufacturing air compressors include vertical boring machines, horizontal boring machines, CNC machines, 3D measuring units, radial drilling machines, dynamic balancing equipment, and ultrasonic cleaning equipment.

Some of the key businesses operating in the global air compressor market are Atlas Copco, Ingersoll Rand, Mitsubishi Heavy Industries, Sulzer Ltd, Ebara Corp, Elgi Equipment Ltd, KPCL, Kobe Steel, Sullair, and VMAC.