Sluijs ... workers and facility safety a priority

Sluijs ... workers and facility safety a priority

Only Total Safety has the people, programs and processes to ensure the safety and health of your staff during critical emergency response operations, says Peter van der Sluijs, General Manager MEA, Total Safety

Worksite safety is no easy feat, since it involves protecting valuable life and property. True to its name, Total Safety is a global leader when it comes to keeping workers, facilities and the environment safe, by providing integrated safety solutions. It is focused in the oil and gas industry, where mission critical equipment is used, and where workers’ strength can run in the thousands at any given time.

'At Total Safety we are passionate about fulfilling our mission statement: W3…to ensure the safe Wellbeing of Workers Worldwide®. We strive to be the preferred global integrated safety solution provider,' Peter van der Sluijs, General Manager MEA, Total Safety, tells Abdulaziz Khattak of OGN.

Worker and facility safety solutions that use the latest available techniques, and technology, is at the core of Total Safety’s business and Sluijs says: 'Only Total Safety has the people, programs and processes to ensure the safety and health of your staff during critical emergency response operations. Our expertise in professional safety services including connected worker and workplace solutions, industrial hygiene services, breathing air systems, gas detection solutions and contingency planning, helps you create the ideal environment for well-planned and safe operations.'

'At the core of our systems and processes lies data,' which Sluijs says can be crucial in pinpointing the location of a problem and averting potential disasters. However, this isn’t just any data; it is data collected instantly.

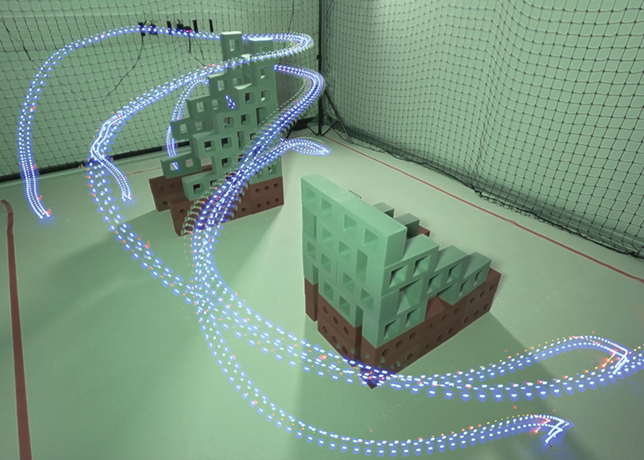

'Total Safety’s Connected Solutions link workers and jobsites to a cloud where important safety data and communication can be monitored from anywhere in real time. This allows us to service our clients from a centralized location on the worksite or remotely without sacrificing worker safety,' says Sluijs.

|

Innovative ... Total Safety's CCSM reduces risk of injury by using less people in |

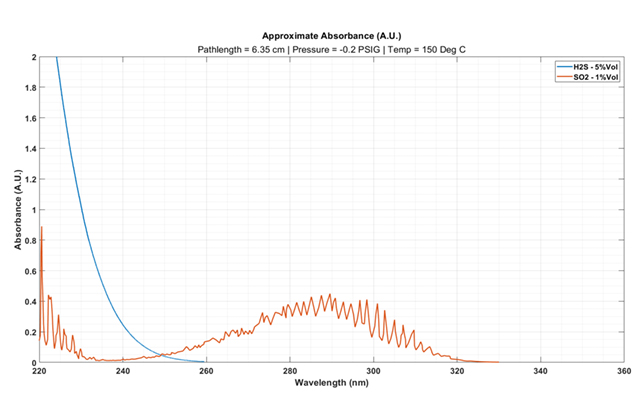

'This technology aims to limit the number of people required to be on-site to perform work since more people mean higher risks.' Sluijs says: 'Usually workers on site carry gas detectors, but they might suppress alarms, or they may not be sure of where the alarm is coming from. This also requires people carrying gas detectors to read and analyze data only after returning from worksites. So, there was a gap for immediate response.

'Because our newest gas detectors allow data logging and analysis in real time, this helps pinpoint the location of the leakage (hazardous gas) allowing operators to resolve the issue immediately to prevent escalation to a dangerous situation,' says Sluijs.

Another benefit of the connected solution technology is that it saves time on productivity and equipment planning. Allowing operators to evaluate the location of people on-site, ensure they are in assigned designated areas, and tracking of all assets on the work site.

SAFETY IN CONFINED SPACES

In 2003, Total Safety founded an innovative confined space monitoring system called Centralised Confined Space Monitoring (CCSM™). CCSM allows companies to reduce risk of injury by using less people in confined space situations. The CCSM model uses a Control Room to monitor confined spaces with innovative and user-friendly risk control process to employ dedicated equipment combined with trained safety operators and technicians. The system utilizes five types of technology: Badge/ID reader technology, fixed gas monitoring, closed-circuit cameras, an alarm system, and communication tools.

|

A Control Room monitors confined spaces with innovative and user-friendly risk |

Sluijs says, 'It’s very important to continuously measure the atmosphere, so as to monitor the level of toxic and/or flammable gases, and oxygen levels. With the old method of recording gas values at night, you couldn’t be sure if the conditions in the confined space would still be the same hours later. This is especially the case in the Middle East where the temperatures of day and night vary drastically.'

'CCSM eliminates the need to manually take readings at worksites before the start of work and repeated every eight hours, allowing us to manage the environment and rescue efforts should an emergency situation arise, and reduces human error.'

'Picture the scenario at a long tower, where workers constantly check in and out. The issue here is to accurately know how many people are in the confined space at any given time. If something untoward is to happen, you need to know how many people are in danger and who they are. Otherwise, you would only be endangering the lives of rescuers,' says Sluijs. The CCSM technology system enables Total Safety to monitor the environment, people, communications, and rescue all from a control room.'

For chemical and petrochemical installations where explosive or toxic gases are likely to occur, Total Safety has the Spider gas detection system, says Sluijs. This system is of great use in partial turnarounds, where only a part of the plant is closed for maintenance. The maintenance area is vulnerable to gases from the operational segments, making it prone to explosions. In such a scenario, the Spider system is placed around the plant and connected to the machines. In an emergency it sounds an alarm and automatically shuts down the equipment.

BRINGING SAFETY CULTURE ON-SITE

Safety in the oil and gas industry has improved tremendously over the past two decades thanks to companies like Total Safety, who are passionate about the safety and wellbeing of people, worksites, and the environment.

To meet the day to day needs of workers, Total Safety provides In-Plant Service Centers (IPSCs), customized to meet the need of each client worksite. This service ensures compliance with local safety standards, by providing personal protective equipment (PPE), personnel training, customised training, educational kits, rental equipment, equipment repair and services, and much more. Today, Total Safety IPSC’s are located in more than 130 plants worldwide.

'The Oil & Gas industry is one of the safest occupations today', says Sluijs. 'However, it’s important to educate workers on workplace regulations through onboarding programs. While these programs might be time consuming for companies, the solution offered by Total Safety is a ‘safety center’, where workers are trained in real life site activities, such as scaffolding, engineering, mechanical work, rescue, CPR and more.'

'There is risk of workers not wearing proper PPE or not having proper training important to performing their job, or proper equipment maintenance which could be devastating. That's where we come in,' says Sluijs.

'The IPSC provides compliance solutions for companies, whose core business does not involve contractor training and management. Total Safety trains the contractors on using PPE, safety procedures and, onboarding. Additionally, Total Safety supplies PPE, such as gas detectors, breathing air components, and gas masks. Our maintenance staff is certified by the manufacturers. All equipment is inspected, serviced and tested after each use and before being re-issued.'

INDUSTRIAL HYGIENE SERVICES

|

Total Safety offers inspections and audits to insure companies are |

Total Safety offers inspections and audits to ensure companies are in compliance with government regulations, industry standards, insurance companies and more. Total Safety follows global regulations such as CE, ATEX, UL, CSA, NFPA, in addition to local requirements like Civil Defense in Saudi Arabia, High Commission of Industrial Security (HCIS).

From choosing the right PPE, measuring occupational noise, chemical, biological or physical hazards, to job site illumination, Total Safety provides solutions and services to make the worker environment safer. Total Safety will document any hazards, provide quality assessments, offer solutions, and create worksite policy and procedures. This reduces the risk of injury or illness to workers and increases productivity.

With the use of historical data Total Safety educates workers by using examples of mistakes made in the past to illustrate what can happen if work is not performed according to protocol. They not only provide comprehensive training, but also instill a safety mindset so workers are aware of safety hazards.

'Before a worker is allowed to enter a worksite, they are required to visit the safety center and pass an onboarding program, which includes training and passing an exam before receiving an access badge,' says Sluijs.

'The onboarding process is especially useful for turnaround projects, when sometimes 300 to 500 people are brought in at the same time.' says Sluijs.

He adds: 'All workers need to be checked for competencies and trained in specific dangers and job duties. We support clients by interviewing, evaluating fit for duty, and training.'

TOTAL SAFETY IN MIDEAST

In the early 2000s, Total Safety expanded into the Middle East. The company’s customer base is growing rapidly and currently serves Saudi Arabia, Qatar, UAE and most recently Oman. They have an employee workforce of 350 people in the Middle East and more than 4,000 people globally.

'More companies are using Total Safety’s technologies and services and acquiring its IPSC concept. In terms of safety levels in the region,' Sluijs says 'The Middle East can do much more. It's difficult for customers to find people, who are trained knowledgeable in safety procedures and technologies. For instance, there aren’t many gas detection specialists in the Middle East. So Total Safety not only provides a technology and smart solutions as a service but is also educating the workforce on the latest safety developments.'

Total Safety is the leading global provider of integrated industrial safety services, equipment and compliance solutions, providing safety equipment, technology and data that make a meaningful difference in the way businesses run. Based in Houston, Texas and operating from 180 locations in more than 20 countries, our nearly 4,000 employees help our customers increase employee health and safety, meet compliance and regulatory requirements, boost productivity and reduce downtime. Driven by our unwavering commitment to our mission …to ensure the safe Wellbeing of Workers Worldwide®, we work across all sectors, including oil and gas, petrochemical and refining, utilities, manufacturing, construction and mining. Visit at www.totalsafety.com to learn more.