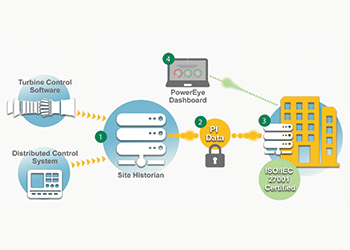

The PowerEye connection architecture maximises the safety of data

The PowerEye connection architecture maximises the safety of data

Armed with intelligence from PowerEye, operators can conduct predictive maintenance and address potential issues before they become costly problems resulting in downtime and equipment failure

Camfil Power Systems has introduced PowerEye, the industry’s first predictive analytics service that quantifies the impact of ambient conditions on the performance of air inlet filtration and combustion turbines. These insights drive higher power output and reduce operational expenses.

The PowerEye engine provides specialised analysis because it pulls from Camfil’s proprietary filtration knowledge base. With years of field-testing experience on a variety of filter types, Camfil has developed algorithms to predict how different filter and atmospheric conditions will react and affect the performance of gas turbines.

Armed with intelligence from PowerEye, operators can conduct predictive maintenance and address potential issues before they become costly problems resulting in downtime and equipment failure.

PowerEye data is delivered through an annual service subscription that is backed by an experienced team of Camfil filtration specialists. These experts provide actionable reports, valuable analysis and critical insights into the status of filters and the performance of gas turbines. Three different subscription levels are available – Lite, Pro and Max – to best accommodate the needs of the operation and budget.

"The information that PowerEye delivers lets power plant operators to maintain better control of their facilities and helps them to make strategic decisions to improve power output across the fleet," said Marc Van den Eynde, Vice President Global Sales and Marketing, Camfil Power Systems.

PowerEye pulls data from three main sources – Camfil’s proprietary PowerEye Air Monitoring Station telemetry device (installed at each facility); the facility site historian and online weather services. Data is securely transferred back to the central PowerEye Server for analysis, then run through the PowerEye Predictive Analytics Engine. The PowerEye engine calculates the impact of ambient conditions on the performance of air inlet filtration and combustion turbines and gives actionable maintenance recommendations to increase plant profitability.

Up to 25 users per site can access PowerEye data and predictions via a web based dashboard. This user-friendly dashboard makes it easy to monitor multiple assets across fleets to spot trends and quickly identify underperforming assets, enabling operators to take appropriate action.