John Long (right) and Mike Weegenhausen

John Long (right) and Mike Weegenhausen

THE fast changing needs of customers in Saudi Arabia’s oil and gas market reflect the rapidly developing nature of the wider Middle East region. OGN puts some questions to John Crane’s John Long, general manager for the Middle East and Mike Weegenhausen, turbomachinery manager for the Middle East, Africa and Asia Pacific to find out how their company is working with its customers to meet those needs.

Excerpts from the interview:

John Crane Saudi Arabia Co Ltd has well-established and long-term relationships with companies such as Saudi Aramco. Do such associations play a part in helping the company become increasingly widely recognised in Saudi Arabia?

That is certainly the case. John Crane’s aim is to become acknowledged as the leading provider of engineered solutions for the process and energy services industries, both in the prominent and rapidly evolving Saudi Arabian market and in the wider Middle East & Africa region. John Crane has been present in Saudi Arabia for more than 20 years and strong partnerships with companies such as Saudi Aramco play a vital role in helping us work towards that aim, particularly by providing direct feedback from our customers in the area.

That feedback is essential in helping us to develop our strategic plans for the Middle East and Saudi Arabia. It helps us ensure that our commitment to the region, and the investment and expansion projects we undertake here, are properly structured so that we can satisfy both the requirements that our customers have today, and those that they will have in the future.

So what level of services and expertise does John Crane currently offer in Saudi Arabia?

We have a very strong local presence in the kingdom, both in terms of providing a wide range of services and equally significantly, as a local manufacturer. We are a Saudi Aramco approved vendor and current levels of Saudisation are 50 per cent, with a clear plan in place to continue to increase this figure, so our links with the area and our local knowledge, are very deeply rooted.

|

John Crane’s Middle East and Africa |

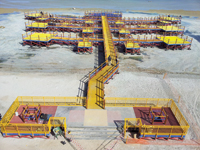

Our Saudi HQ, Service and Manufacturing facility is based in Dammam and our ongoing investment programme in Saudi Arabia has helped us create an impressive range of facilities, including separate strip, inspect, reconditioning and test facilities for both wet seals and dry gas seals. This allows us to test the full range of our dry gas seal installed base in kingdom, which is unique. Dammam also boasts an impressive state-of-the-art CNC machine shop, a large central parts warehouse and a comprehensive refurbishment and balancing capability for our wide range of Metastream power transmission couplings.

Also based in Dammam are our customer service, operations chain and engineering, HR and finance teams. Dammam also has a fully equipped training centre where customers can learn how to optimise their own John Crane equipment. In short, we have everything we need in kingdom, and this allows us to provide customers in Saudi Arabia with everything they need to keep their assets operating at maximum efficiency.

Does this translate into real benefits for your customers?

Generally speaking, our customers aim is to achieve improved levels of reliability, greater operating efficiency and better maintenance programmes which are as efficient and effective as possible. Our facilities in Saudi Arabia mean that they can now access the products and specialist services they need to achieve those aims, quickly and efficiently, from a local source. That results in benefits such as shorter turnaround times on refurbishment work, more rapid access to specialist advice and guidance, and greater availability of spares. These local facilities also give customers easy access to many other products from the John Crane portfolio, such as seal support systems, filtration systems and advanced hydrodynamic bearings.

Different customers have very different requirements, and our teams in Saudi Arabia have a detailed understanding of those requirements and of the characteristics of the different sectors in which those customers operate. As a result of this, we are able to offer each customer a genuinely tailored solution which is suited to their individual needs. We can also help them to comply with the relevant regional, national and international standards on issues such as quality, environmental performance and health and safety.

We have made our wish to work in partnership with our customers in Saudi Arabia quite clear, so it is a natural step for us to provide them with dedicated support and to deliver products and services that are world-class in terms of quality, performance, innovation and support.

Do you have other facilities in Saudi Arabia?

Yes we do. In Jubail we have a fully equipped service centre with full wet seal strip, inspect, reconditioning and test facilities, plus a product and service training centre and a team of field service engineers who are always on hand to provide customers with dedicated on-site support. Our service centre in Yanbu is currently being upgraded to a 500 sq m facility, complete with inventory, to further support the customers on the West coast and reduce lead times.

Together with our Dammam headquarters this means we can support our customers throughout the whole of Saudi Arabia. Our investment and expansion means that we will continue to support Saudi Aramco’s own future plans whilst improving our own in kingdom capabilities, and that can only be good news for our customers.

It’s important to remember that our growth in Saudi Arabia is a part of our expanding offering to the Middle East region. That itself has seen considerable expansion in recent times, such as the opening of our MEA Service & Manufacturing facility in Dubai.

Do customers in Saudi Arabia benefit from this wider network at all?

Again, the answer is a definite ‘yes’. An excellent example of this is our Dubai-based John Crane MEA Turbomachinery Group, which provides specialist turbomachinery support services to customers across the Middle East, Africa and the Caspian region.

The Turbomachinery Group works in partnership with John Crane customers and provides support in a number of different areas. Its overall aim is to significantly improve reliability levels for customers, while providing rapid response times to any service, failure investigation or technical issues those customers might encounter.

The group was created in 2010 in response to a very strong demand in the region for this type of specialist support. The fact that it is the only turbomachinery group of its type that is based in the Middle East reflects John Crane’s commitment to our customers offering unprecedented access to the company’s wealth of expertise on all types of turbomachinery applications.

What services does the group provide?

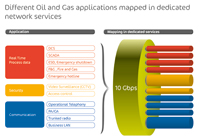

The group members are drawn from various turbo specialist disciplines and have considerable expertise in dry gas seals, filtration, hydrodynamic bearings, thermoplastic labyrinths, high performance couplings and control and gas conditioning systems. They come together to create a multi-skilled and highly focused team that provides a wide range of services such as root cause analysis (RCA), field installation, commissioning, site audits and training, all of which are tailored to suit the specific customer needs.

The group has a range of dedicated resources and processes at its disposal and has already achieved some significant successes. In the Middle East for example, John Crane was recently awarded a number of major turnkey contracts to retrofit the sealing systems for centrifugal compressors, from traditional oil seals to dry gas seals and seal gas control panels. These type of contracts also require rotor dynamic analysis to be conducted, which highlights whether the existing bearing set-up is adequate, as in some cases new damper bearings may also be required due to the change in rotor dynamics. The specialist expertise provided by the Turbomachinery Group played a significant role in winning this new business. That expertise was also key in highlighting the fact that John Crane can undertake the role of prime contractor for this type of project, and provides a proven and integrated package of products that includes dry gas seals, control panels, hydrodynamic damper bearings and power transmission couplings.

When managing complete turnkey seal retrofit projects, the group is able to handle every aspect right from the initial review of the existing system through to the final connections and tie-ins, as well as providing ongoing support for the new installation. It also supports John Crane’s new state-of-the-art gas seal service facility in Dubai, through dry gas seal improvement programmes such as upgrades and seal management programmes.

The Turbomachinery Group team adopts a proactive approach, looking well beyond the immediate seal environment to identify ways in which the customer can optimise the reliability of their plant. This reflects the fact that John Crane can provide full end-to-end solutions for turbomachinery applications that include whatever package of products and services is most appropriate for each individual customer.