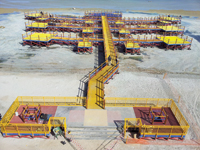

The group has made huge investments in pipe corrosion control services

The group has made huge investments in pipe corrosion control services

ESTABLISHED in 1940s, Abdel Hadi Abdullah Al Qahtani Group of Companies is considered to be one of the largest and most reputed privately-owned companies in Saudi Arabia with excellent relationships in both government and commercial sectors.

Headquartered in Dammam, the biggest city in the Eastern Province of Saudi Arabia, the group has over the decades, diversified and expanded to cover various business activities broadly divided into trading and contracting; industry; services; farming and overseas services.

The group initially started its business with its first company – Abdel Hadi Abdullah Al Qahtani & Sons Co in the early 40s as a wholesaler and supplier of food products. As the business grew and expanded, it diversified into supplying other industries including petrochemicals, oil and gas exploration and gathering systems, refineries, fertiliser plants, desalination and other energy related fields.

Apart from energy related and industrial supplies and the long established wholesale food division, the group furnishes medical instruments and supplies, recreational equipment, computer software and hardware, other IT services, consumer products and vehicles and machinery.

The group has gradually moved towards oil and gas and non-oil and gas related activities. Huge investment and facilities in pipe corrosion control services, manufacturing of medium and large diameter steel pipes, water treatment chemicals, nails and galvanised wire manufacturing, industrial and medical gases, water bottling, and bulk food packaging now form a major part of the group’s activities.

From time to time, it has also added new activities such as insurance, travel and tourism, transportation and custom clearance, besides the other specialised services such as pipe inspection, environmental protection, real estate investment, car parking services and others.

Al Qahtani group has established a presence in the contracting and construction industry also. It is a leader in new technologies and is associated with well-known industries to carry out major projects in the kingdom.

Furthermore, the group owns vast areas of agricultural land used for wheat and cereal farming, fruit tree plantations, and breeding of cattle and pure Arabian horses.

On the other hand, the group in order to diversify its investment portfolio in the early 70s established offices in the GCC, the Middle East, Europe and the US to help promote business within the area and enhance the image of the group.

The group is involved with international firms in joint venture manufacturing projects.

A staff of highly qualified and dedicated professionals operates the business. Customer service is a priority and is facilitated by a wide variety of technical expertise and experienced personnel employed by the group.

The group is managed by leaders with vision and ambition, dedicated to developing further opportunities in partnership with new and existing clients.

Today, the group’s business activities have extended to other Middle Eastern countries. The group has an excellent reputation as a long established supplier of materials, equipment, engineering services and other products to Saudi Aramco, SEC, Sabic, SWCC and many other government agencies as well as the private sector.

OIL FIELD SUPPLIES & SERVICES

The division is involved since early 50s in supply of oil field products and services in the kingdom. Saudi Aramco and other oil companies, petrochemical industries, utility companies, EPC/pipeline contractors, military and educational institutions have been its main clients.

Construction and engineering division: The company established a construction and engineering division in the early 90s to execute its projects in the field of mechanical, civil, electrical and instrumentation disciplines associated with major international companies to execute several projects in Saudi Arabia.

The division has completed a few projects during the last few years involving: Supply and erection of cooling towers at the King Fahd Military Medical Centre; engineering design, supply and installation of fuel gas dust/liquid separator equipment in SEC Qurayyah power plant; grease and seal wellhead valves in the Saudi Aramco industry; refurbishment of waste-water tanks at King Fahd Military Medical Centre; study of corrosion, engineering and supply of heat exchangers / boiler tube shield and their installation in Saudi Aramco and Sabic Industries.

Environmental engineering services division: The company has taken the initiative of expanding in the field of environmental engineering services. In a common trend with other countries there is a growing concern for safeguarding the environment and clean up of hazardous waste in the Middle East.

It has acquired and set up a complete facility to treat oily waste through state-of- the-art technology. The facility’s equipment is manufactured by one of the world leader’s in centrifugal separation technology. The latest technology is part of their wide range of separation equipment.

The company by executing several projects for Saudi Aramco in the kingdom, is well placed and equipped with the machinery, systems, qualified manpower and logistical support to carry out oily waste recovery and clean-up projects.

Pipe & Well Services Establishment: PWS, an ISO 9001 certified company, was incorporated in 1992 to provide a wide range of inspection, testing and certification services to the oil and petroleum industry. There was a need in the market to provide high quality services at very competitive rates through a professionally organised company, which enjoys the reputation and creditability of overseas inspection companies.

PWS is the tubular inspection specialist company in the group which has grown up in multiples in last ten years matching with latest technologies and development.

PWS is successfully continuously serving Saudi Aramco since 1996. Recent achievement of the fourth contract from Saudi Aramco has added a feather in its cap. The company is serving other industries as well other than the oil and petroleum industry.

• Services: PWS offers various services to industry through inspection teams consisting of qualified and certified inspectors (ASNT certified) and have performed inspection jobs throughout Saudi Arabia. The company is accepted as a well-reputed organisation related to inspection, testing and certification services.

Al Qahtani Pipe Coating terminal: Saudi Arabia has experienced major developments in the pipeline industry. To meet the demands of the harsh environment and for the protection of cross-country and sub-sea oil, water and gas pipelines against corrosion, Al Qahtani Pipe Coating terminal was established in 1954.

Since those early days when coat and wrap was used, the company has rapidly moved to new technological advantages available today and has three separate facilities in the kingdom equipped with the latest coating technology.

Internal fusion bonded epoxy (FBE) coating: Al Qahtani Pipe Coating applying FBE to internal surfaces of pipes, fittings, spools and downhole tubular’s FBE can apply for sizes from 2-1/2-inch to 80-inch OD. Internal fusion bonded epoxy coating can be used for treated seawater service, sour gas, Gtude service, Wasia water service and potable water.

Double jointing: Since 1978 the double jointing plant utilises a five station double – jointing system to join two 40 foot sections of pipe into one 80 foot section for diameter of 10-inch to 60-inch.

Double jointing contributes to substantial transportation savings and reduces the number of field weld by one – half. After the welding is completed 100 per cent X-Ray is performed. Al Qahtani’s radiographic film processing facility is equipped with two fully automatic film processing units for speed and reliability.

Internal shop or field girth weld coating: Al Qahtani Pipe Coating developed the capability to coat the internal girth weld area of the coated pipe from 10-inch and up to 60-inch diameter.

Capabilities can be developed for larger diameters if so required by clients. The service contributes to providing an end-to-end corrosion protection system with fusion bonded epoxy using.

Coating for heat exchangers, vessels and boilers: Applied coating on internal and external surface of tube bundles, vessels, tanks to prevents foulings and incrustation in the heat exchangers and enhances life of the same. Maintenance/cleaning costs are greatly reduced due to less maintenance requirement.

Al Qahtani Pipe Coating was the first to offer sakaphen coating technology in the Middle East.

Fabrication (welding) of spools, sleeves: Shop welding has advantages over field welding. Spools can be welded and coated in the location in ideal conditions.

Pipeline Rehabilitation: Al Qahtani Pipe Coating line travel equipment for hydro-blast cleaning grit preblasting, spray liquid coating of the external surface of pipe. Pipelines where tape coatings or similar coating has failed can be field rehabilitated in situ techniques to remove failed coating and reapplied with liquid coating.

External fusion bonded epoxy coating: Al Qahtani Pipe Coating was the first applicator in the Middle East to apply external fusion bonded epoxy coating from 2-inch and up to 80-inch, single layer or dual system for stander and high temperature.

• Services: Concrete coating by compression method is applied to pipe diameters from 3-inch and upto 60-inch with coating thicknesses ranging from 1-inch to 6-inch and concrete densities is 190 pounds per cubic foot. The compression method can apply concrete coating over any type of corrosion coating FBE, collar and three layer polyethylene or polypropylene.

External three-layer polyethylene/polypropylene: Al Qahtani Pipe Coating was the first in the world to apply three layer polyethylene coating on 80-inch diameter pipe for SWCC (Saline Water Conversion Corporation) Water Pipeline Project. Three layer polyethylene or polypropylene can be applied from 3-inch and upto 80-inch diameter.

Custom coatings: Al Qahtani has the most modern and technically advanced facility which includes enclosed manual blasting with automatic speed control for applying external/internal, high temperature liquid and powder coating, to all types of fabricated spools, fittings, bends and valves.